Storage unit manufacturing method and apparatus

A manufacturing method and memory technology, applied in semiconductor/solid-state device manufacturing, electrical components, transistors, etc., can solve problems such as high contact resistance and leakage current deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

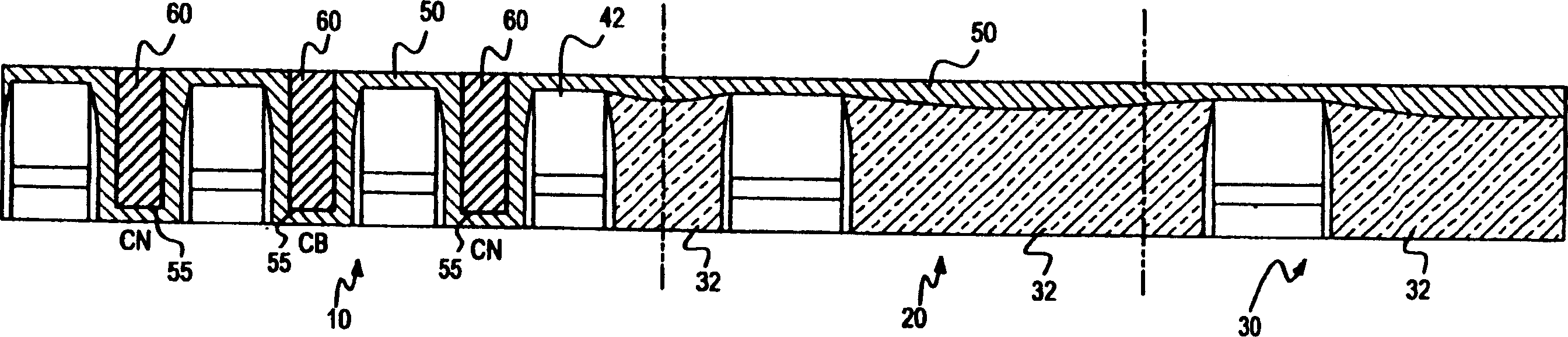

[0018] The main object of the present invention is to form a double-layer plug containing polysilicon layer and tungsten metal in the memory cell area inside the memory, so that the memory cell area has both low leakage and low contact resistance characteristics, and achieves the purpose of improving the speed of the memory. The front-end manufacturing process of forming memory cells and the back-end manufacturing process of forming capacitors, interconnection wires, and passivation layers are not the object of protection of the present invention, so the following descriptions are only briefly described and not repeated.

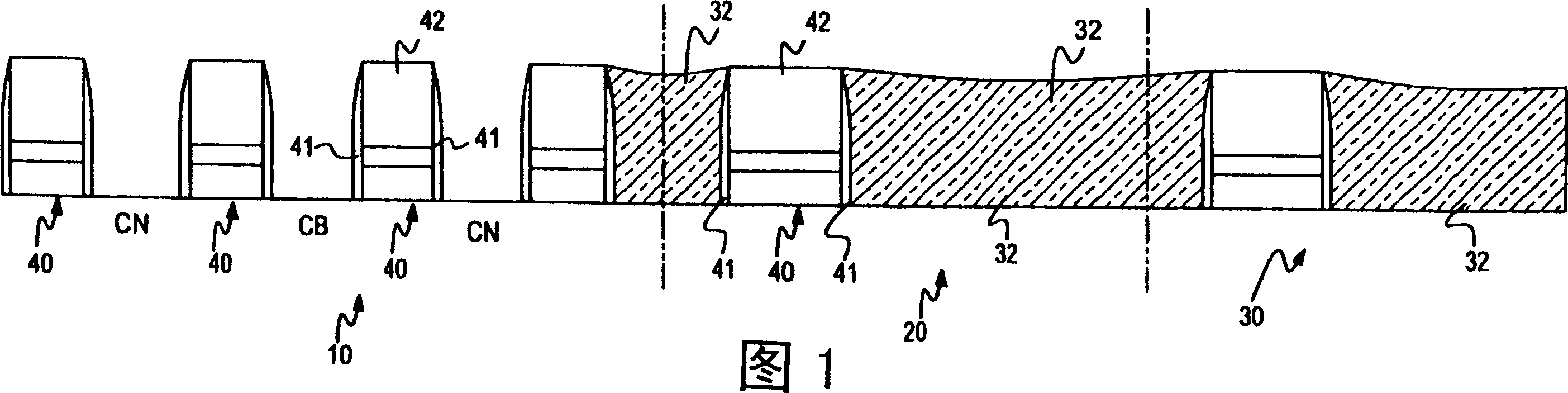

[0019] Referring to FIG. 1 , it is a schematic cross-sectional view of a memory. Firstly, the substrate area with DRAM memory cell area 10, DRAM peripheral area 20, and logic circuit area 30 is formed on a silicon substrate, wherein the transistors in each area are formed in the substrate through the previous manufacturing process, which can be seen in FIG. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com