MOSFET device with silicon carbide inverted T-shaped masking layer structure and preparation method thereof

A masking layer, silicon carbide technology, applied in the field of microelectronics, can solve the problems affecting the forward blocking characteristics of the device, and achieve the effects of reducing the JFET effect, reducing the electric field concentration, and improving the breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

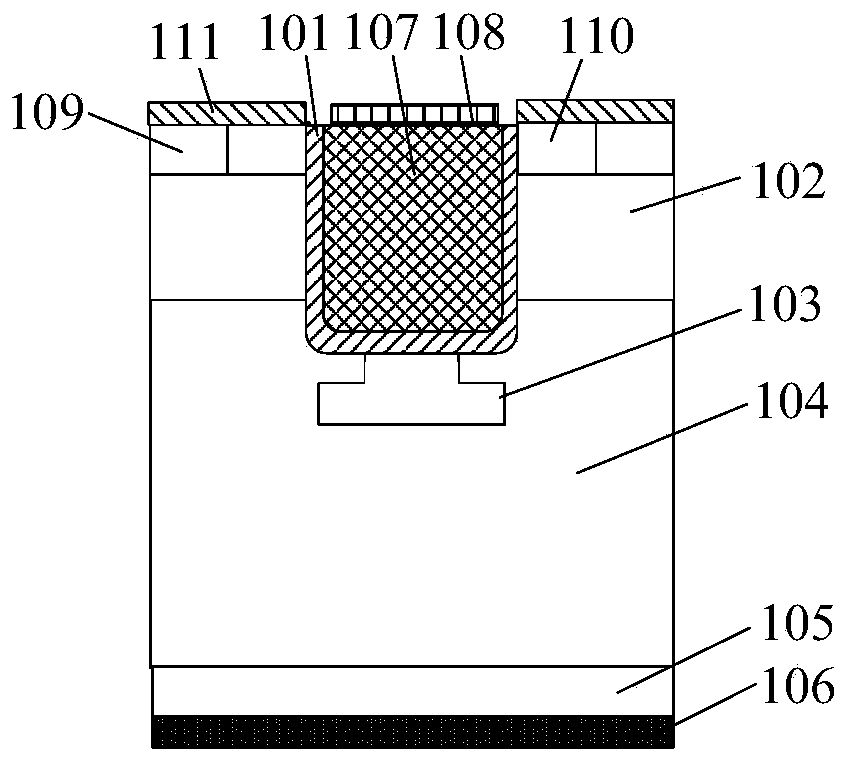

[0049] See figure 1 , figure 1 A schematic cross-sectional structure diagram of a MOSFET device with a silicon carbide inverted T-shaped mask layer structure provided by an embodiment of the present invention.

[0050] A MOSFET device with a silicon carbide inverted T-shaped masking layer 103 structure, comprising:

[0051] gate dielectric layer 101;

[0052] a base region 102 located on both sides of the gate dielectric layer 101;

[0053] a masking layer 103 located on the lower surface of the gate dielectric layer 101;

[0054] a drift layer 104 located on the lower surface of the base region 102 and the masking layer 103;

[0055] a substrate layer 105 located on the lower surface of the drift layer 104;

[0056] The drain 106 is located on the surface of the substrate layer 105;

[0057] a polysilicon layer 107 located on the inner surface of the gate dielectric layer 101;

[0058] The gate 108 is located on the upper surface of the polysilicon layer 107 .

[0059...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com