System of using LNG cold energy in spray cooling of air cooling tower

A technology of spray cooling and air cooling tower, which is applied in water shower coolers, applications, household appliances, etc. It can solve the problems of low heat transfer efficiency of air cooling towers, achieve the effects of lowering temperature, improving heat transfer performance, and improving heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with accompanying drawing and example:

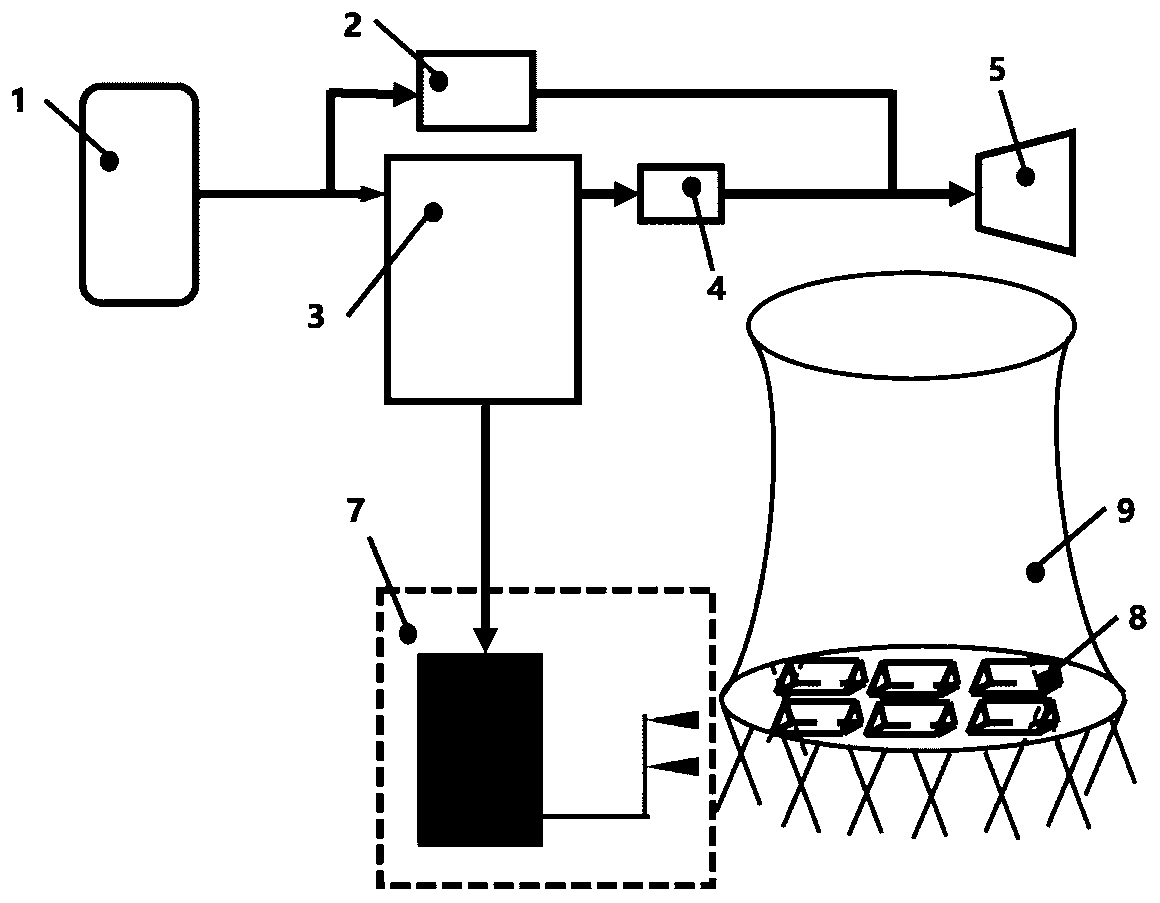

[0025] Such as figure 1 Shown, a kind of LNG cold energy provided by the present invention is used for the system of air-cooling tower spray cooling, comprises:

[0026] The LNG gasification system arranged beside the LNG storage tank 1. The LNG gasification system is connected in parallel with the LNG cold energy utilization system 3 . When the cold energy of LNG is utilized, part of the LNG enters the high-pressure water-bath gasifier 2 for gasification, and then enters the gas turbine 5 as fuel.

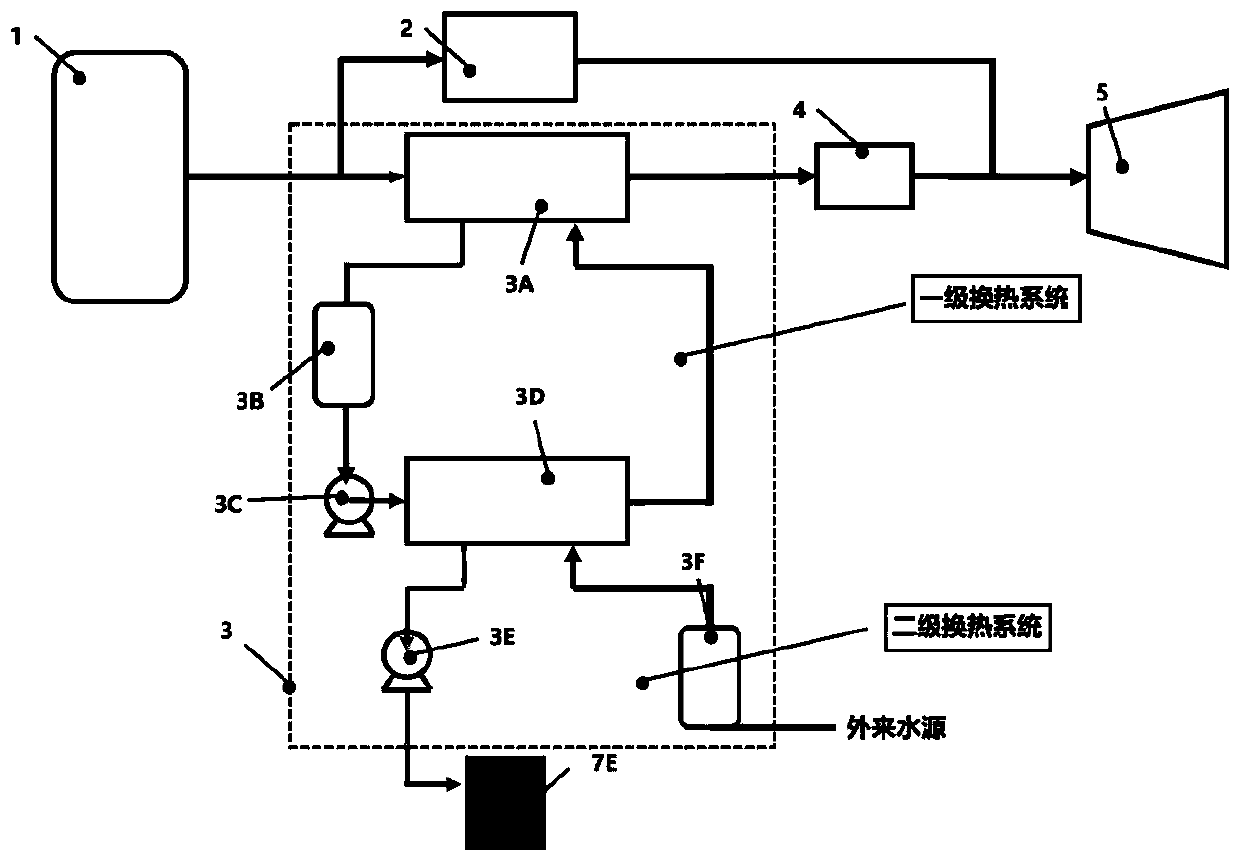

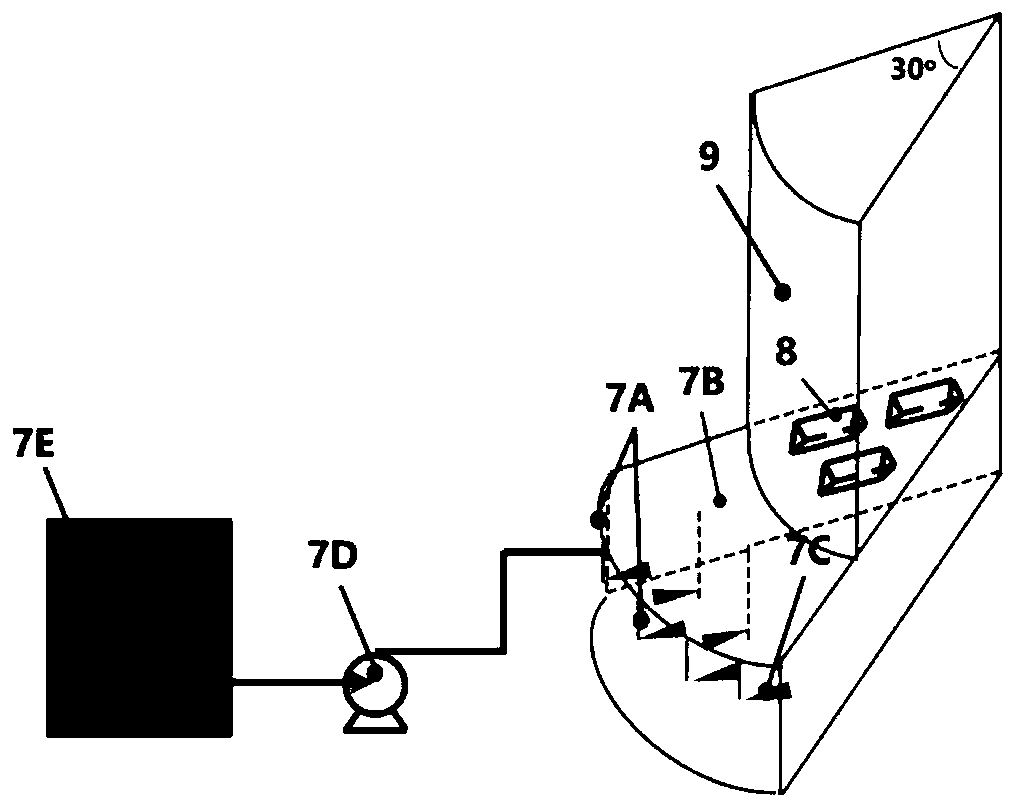

[0027] Such as figure 2 As shown, the LNG cold energy utilization system 3 includes a two-stage heat exchange system. Under normal operating conditions, the refrigerant in the refrigerant storage tank 3B of the primary heat exchange system passes through the refrigerant pump 3C of the primary heat exchange system and enters the heat exchanger 3A of the primar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com