Production method of cellulose-based hydrogel adsorber used for treating heavy metal wastewater

A hydrogel adsorbent and cellulose-based technology, which is applied in the field of preparation of cellulose-based hydrogel adsorbents, can solve the problems such as the inability to realize the recovery and reuse of cellulose-containing textile waste resources and the limited adsorption capacity of heavy metal ions. , to achieve the effect of strong heavy metal adsorption capacity, excellent hydrophilicity, efficient and rapid removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

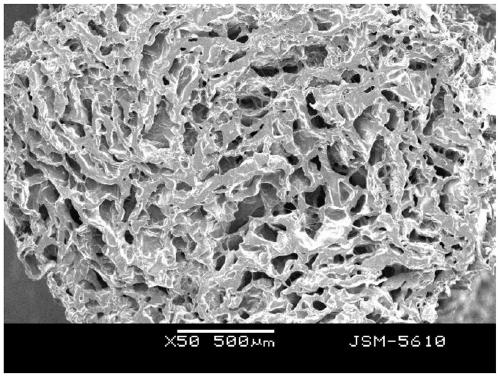

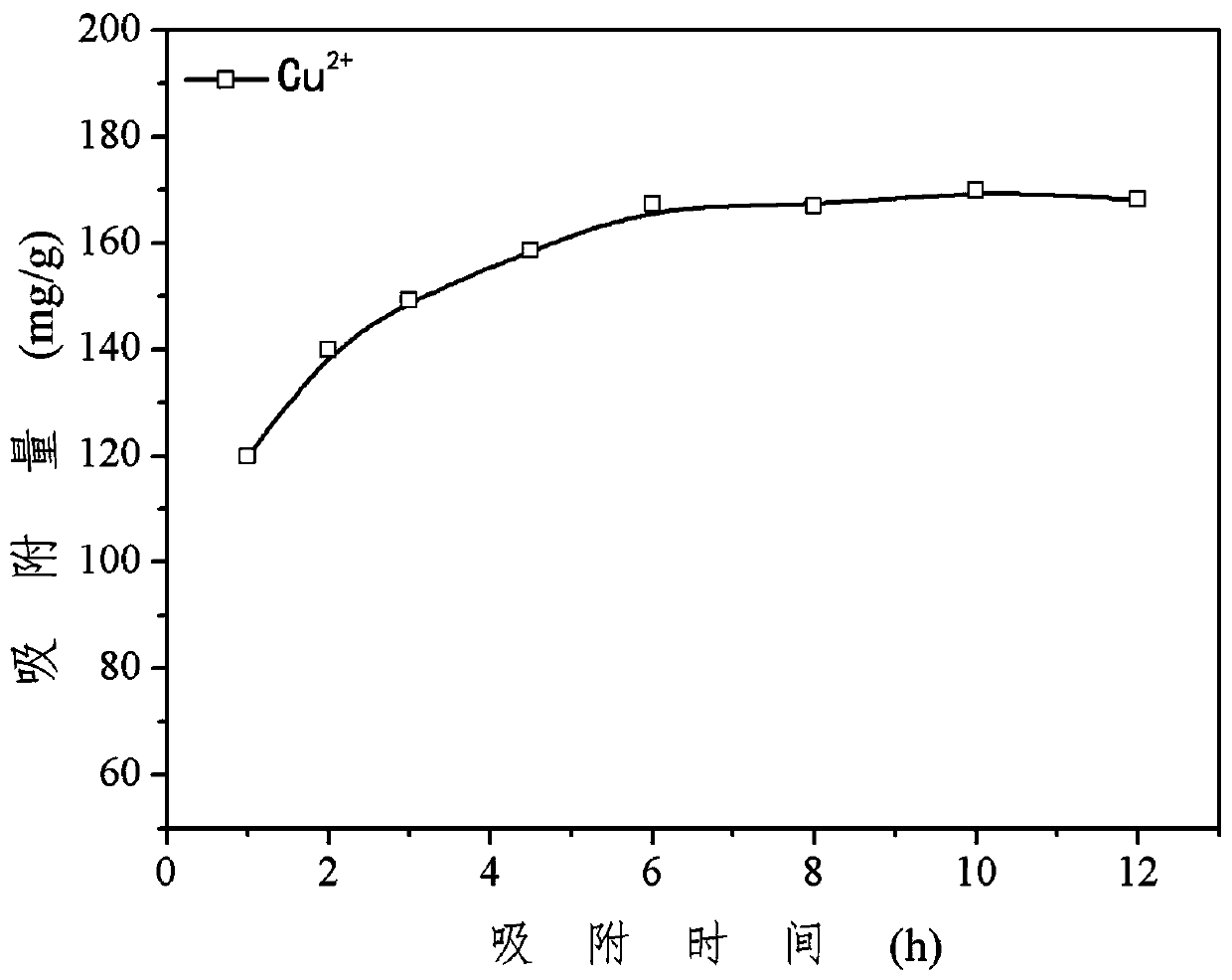

Image

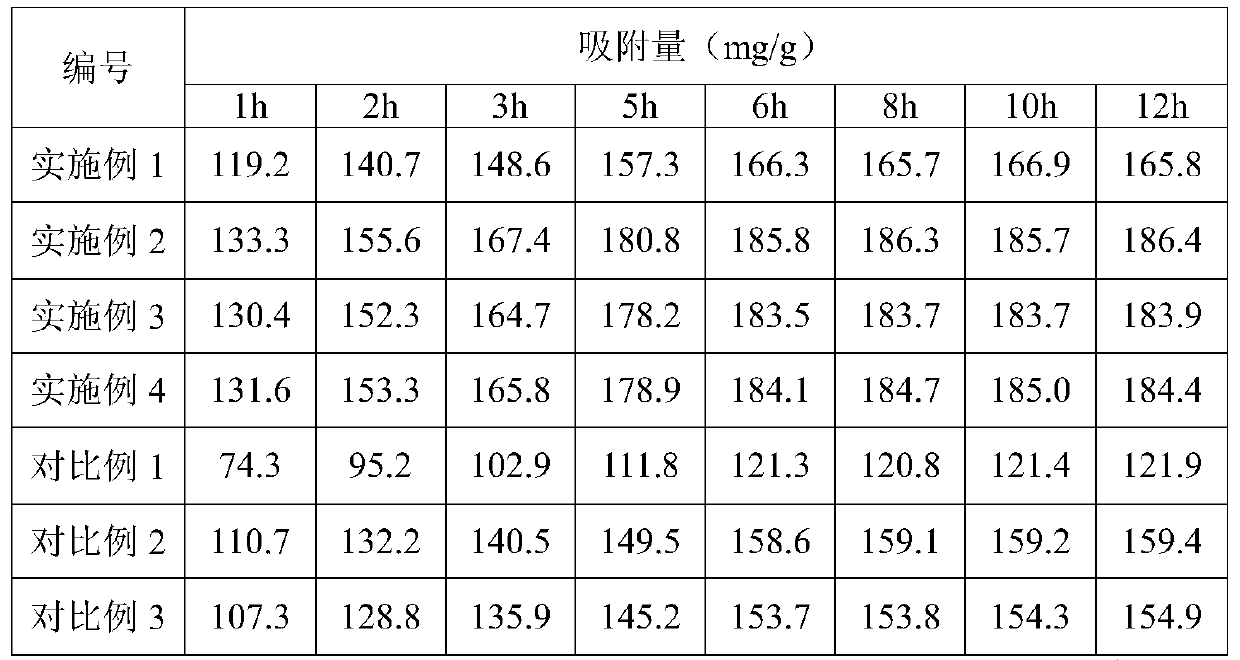

Examples

Embodiment 1

[0031] Preparation of cellulose solution: Weigh the dried cotton yarn and place it in the cellulose solution (a mixed solution of 7wt% NaOH and 12wt% urea), stir and disperse fully, and freeze at -15°C for 2 hours to obtain the cellulose solution. Cotton yarn and fiber The mass ratio of the solution solution is 1:15.

[0032] Preparation of modified solution: Add sodium hydroxide to the mixed solution of dimethyl sulfoxide, epichlorohydrin and triethylenetetramine, stir evenly to obtain a modified solution, sodium hydroxide, dimethyl sulfoxide, epoxy The mass ratio of chloropropane and triethylenetetramine is 1:50:4:4.

[0033] Preparation of gel-like polymer: Add 60g / L polyvinyl alcohol solution to the cellulose solution, mix well, then add ammonium persulfate, acrylic acid monomer and N,N-methylenebisacrylamide in sequence, at 25°C Stir and polymerize for 20 hours to obtain a gel-like polymer; the mass ratio of cellulose solution, polyvinyl alcohol solution, ammonium persul...

Embodiment 2

[0036]Preparation of cellulose solution: Weigh the dried cotton yarn and place it in the cellulose solution (a mixed solution of 7wt% NaOH and 12wt% urea), stir and disperse fully, and freeze at -15°C for 2 hours to obtain the cellulose solution. Cotton yarn and fiber The mass ratio of the solution solution is 1:15.

[0037] Preparation of modified solution: Add sodium hydroxide to the mixed solution of dimethyl sulfoxide, epichlorohydrin and triethylenetetramine, stir evenly to obtain a modified solution, sodium hydroxide, dimethyl sulfoxide, epoxy The mass ratio of chloropropane and triethylenetetramine is 1:50:4:4.

[0038] Prepare modified activated carbon: add activated carbon to 8M nitric acid solution, the mass volume ratio of activated carbon to nitric acid solution is 1g:20mL, stir at 65°C for 9h, filter and wash, then dry at 90°C to obtain oxidized activated carbon; in the obtained oxidized activated carbon Add thionyl chloride to the mixture, the mass ratio of oxid...

Embodiment 3

[0042] Preparation of cellulose solution: Weigh the dried cotton yarn and place it in a cellulose solution (a mixed solution of 5wt% NaOH and 10wt% urea), stir and disperse fully, and freeze at -20°C for 1 hour to obtain a cellulose solution. Cotton yarn and fiber The mass ratio of the solution solution is 1:10.

[0043] Preparation of modified solution: Add sodium hydroxide to the mixed solution of dimethyl sulfoxide, epichlorohydrin and triethylenetetramine, stir evenly to obtain a modified solution, sodium hydroxide, dimethyl sulfoxide, epoxy The mass ratio of chloropropane and triethylenetetramine is 1:60:5:5.

[0044] Prepare modified activated carbon: add activated carbon to 10M nitric acid solution, the mass volume ratio of activated carbon to nitric acid solution is 1g:40mL, stir at 75°C for 11h, filter and wash, then dry at 110°C to obtain oxidized activated carbon; in the obtained oxidized activated carbon Thionyl chloride was added to the mixture, the mass ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com