Reaction kettle device for high-performance polyphenylene sulfide composite material

A technology of polyphenylene sulfide and composite materials, applied in chemical/physical/physicochemical fixed reactors, cleaning methods and utensils, cleaning hollow objects, etc., to achieve efficient stirring, high-efficiency stirring effect, and avoid the effect of raw material accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

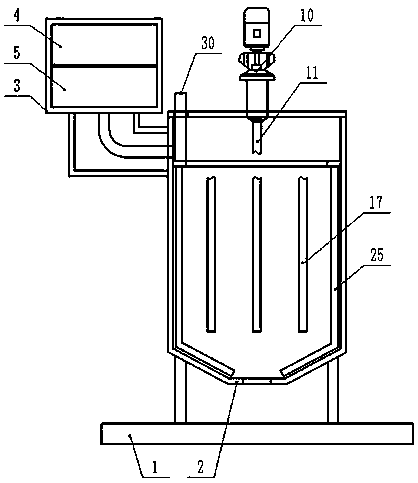

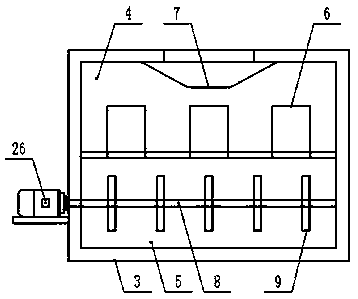

[0016] Example 1: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6, a reactor device for a high-performance polyphenylene sulfide composite material provided by the present invention is now described, including a base base 1 and a reactor body 2 provided on the upper end of the base base 1, and the lower end of the reactor body 2 is connected to the Support columns are evenly arranged between the upper ends of the base base 1, the upper end of the reaction kettle body 2 is hollow cylindrical, and the lower end is hollow mud bucket-shaped, and a material preparation box 3 is arranged on the outer side of the top of the reaction kettle body 2. The middle side of the inner cavity of the material preparation box body 3 is horizontally provided with an interlayer and the interlayer divides the inner cavity of the material preparation box body 3 into an upper guide material grinding chamber 4 and a lower stirring and drying chamber 5, and the upper guide ma...

Embodiment 2

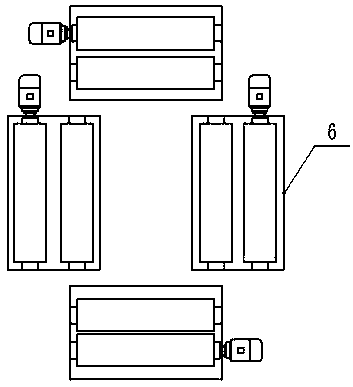

[0017] Example 2: see figure 1 , figure 2 , image 3 , a kind of reactor device for high-performance polyphenylene sulfide composite materials provided by the present invention will now be described, and a support installation frame is provided between the outer bottom end of the material preparation box 3 and the outer end wall of the top of the reactor body 2 , the collection bin 7 is a hollow truncated circular shape with an open upper end and a cover plate at the lower end. The bottom end of the inner cavity is evenly connected with a guide pipe and the discharge end of the guide pipe is respectively connected to the upper port of the guide cylinder 6. The guide cylinder 6 is hollow and rectangular, and the guide cylinder 6 A group of grinding rollers are respectively arranged in parallel at horizontal intervals inside, and first motors are respectively provided on the outer end walls of the material guide cylinder 6, and the output shafts of the first motors extend int...

Embodiment 3

[0018] Embodiment 3: see figure 1 , Figure 4 , Figure 5 , a kind of reactor device for high-performance polyphenylene sulfide composite materials provided by the present invention is now described, the middle part of the bottom end of the reactor body 2 has a discharge port, the solid raw material feeding port, the inner end of the liquid raw material feeding port Each is detachably equipped with a cover plate, the inner cavity at the bottom of the lower stirring and drying chamber 5 communicates with the inner cavity at the top of the reaction kettle body 2 through a pipeline, and the inner end of the discharge port and the bottom of the lower stirring and drying chamber 5 The inside of the discharge end is respectively equipped with an electric control switch valve, the drive assembly 10 includes a drive motor, a reducer and a magnetic coupler, the top end plate of the reaction kettle body 2 is detachable, and the strip groove 14 The adjacent ends are respectively connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com