Methanol rectifying tower

A technology of methanol rectification tower and tower body, which is applied in the field of methanol rectification tower, can solve the problems of difficult recycling, poor condensation effect, heat energy consumption, etc., and achieve the advantages of easy recycling and reuse, favorable cooling treatment, and reduced contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

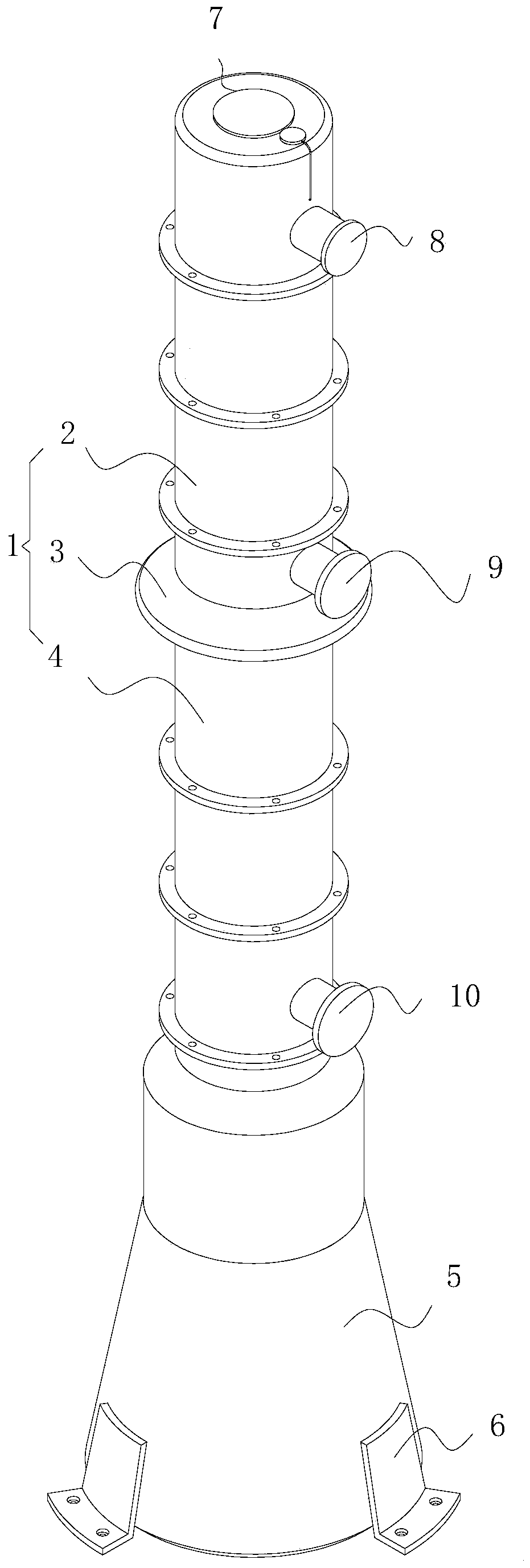

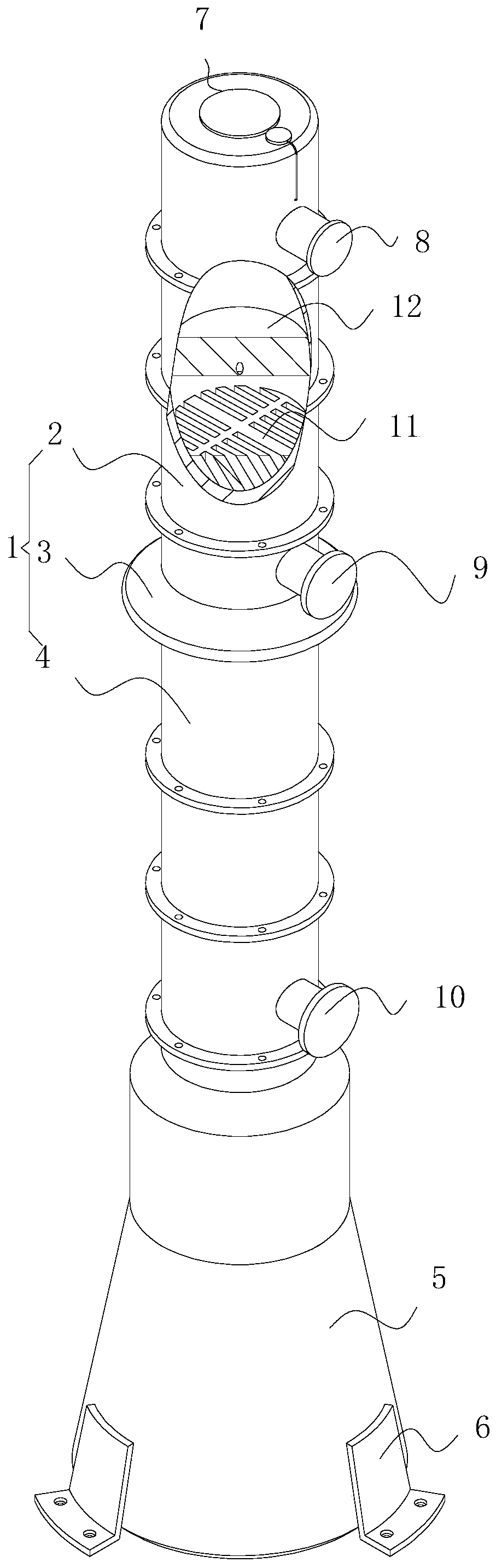

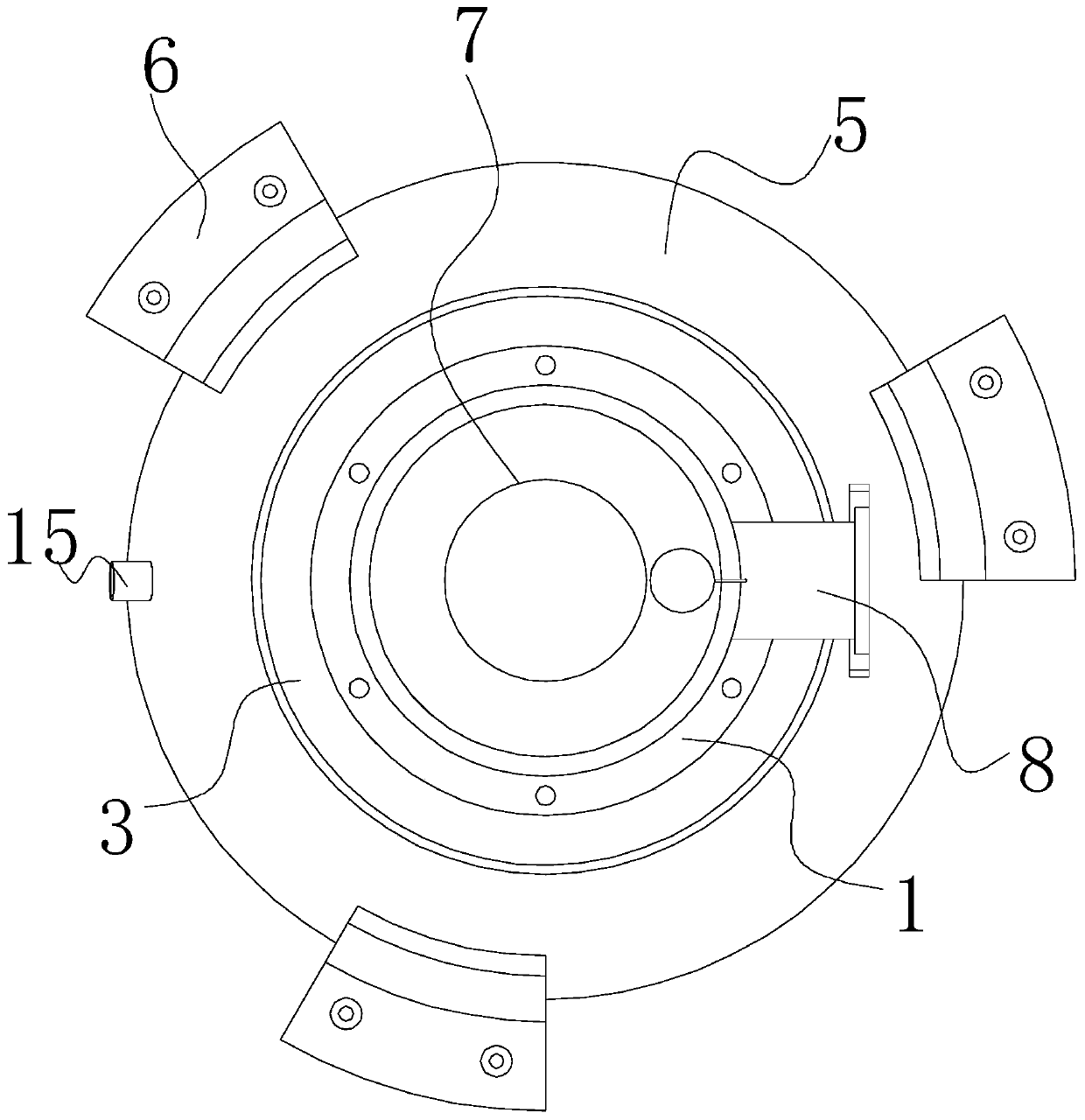

[0038] Such as Figure 1-7 As shown, the present invention provides a technical solution: a methanol rectification tower, comprising a tower body 1, the upper part of the tower body 1 is a packed tower section 2, the middle part of the tower body 1 is a connecting tower section 3, and the connecting tower section 3 It can be installed to reduce or avoid the residual part of the inner wall, and effectively recycle. The lower part is a plate tower section 4, the lower part of the tower body 1 is fixedly connected with a concrete base 5, and the side of the concrete base 5 is welded with a plurality of reinforced angle steel seats 6. It can be easily installed stably. The top of the tower body 1 is also provided with a steam outlet 7, which can facilitate the discharge of heat energy. The side of the tower body 1 is provided with a reflux liquid inlet 8, a methanol liquid inlet 9 and a mixture inlet 10 in sequence from top to bottom. The inner wall of the packed tower section 2 i...

Embodiment 2

[0041] The connecting tower section 3 includes an connecting body 301, a flow-to pipe 302 and a cooling fin 303, and the connecting body 301 is composed of a similar upper circular platform A30101 and a similar lower circular platform B30102. It is connected and the interior is hollow, and the upper circular platform A30101 and the lower circular platform B30102 are oppositely arranged. The combination of the upper circular platform A30101 and the lower circular platform B30102 is set, and the liquid refined methanol falls from the inner wall of the packed column section 2 to the connecting column. Section 3, from the upper circular platform A30101 to the lower circular platform B30102, and from the lower circular platform 30102, falls to the inside of the plate column section 4, which can effectively reduce the contact of liquid refined methanol on the inner wall of the plate column end 4, which can facilitate recovery and Reuse, and the upper end of the similar upper round pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com