Light-emitting electrochemical cell and preparation method thereof

A technology of light-emitting electrochemical cells and light-emitting materials, which is applied in the field of preparation of light-emitting electrochemical cells, can solve the problems of poor stability and low light-emitting performance, and achieve the effects of improving device performance, reducing crystallinity, and improving phase separation of thin films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

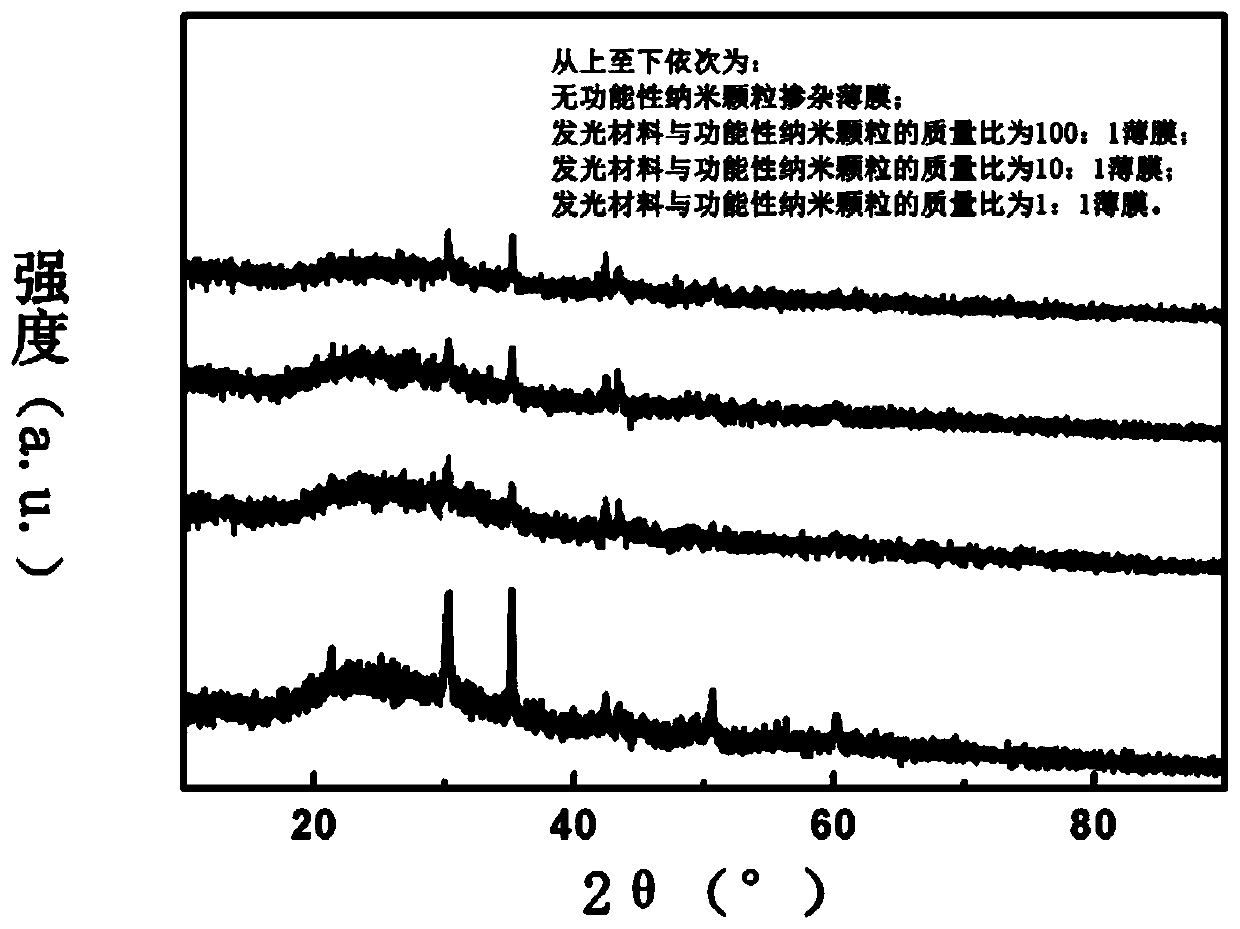

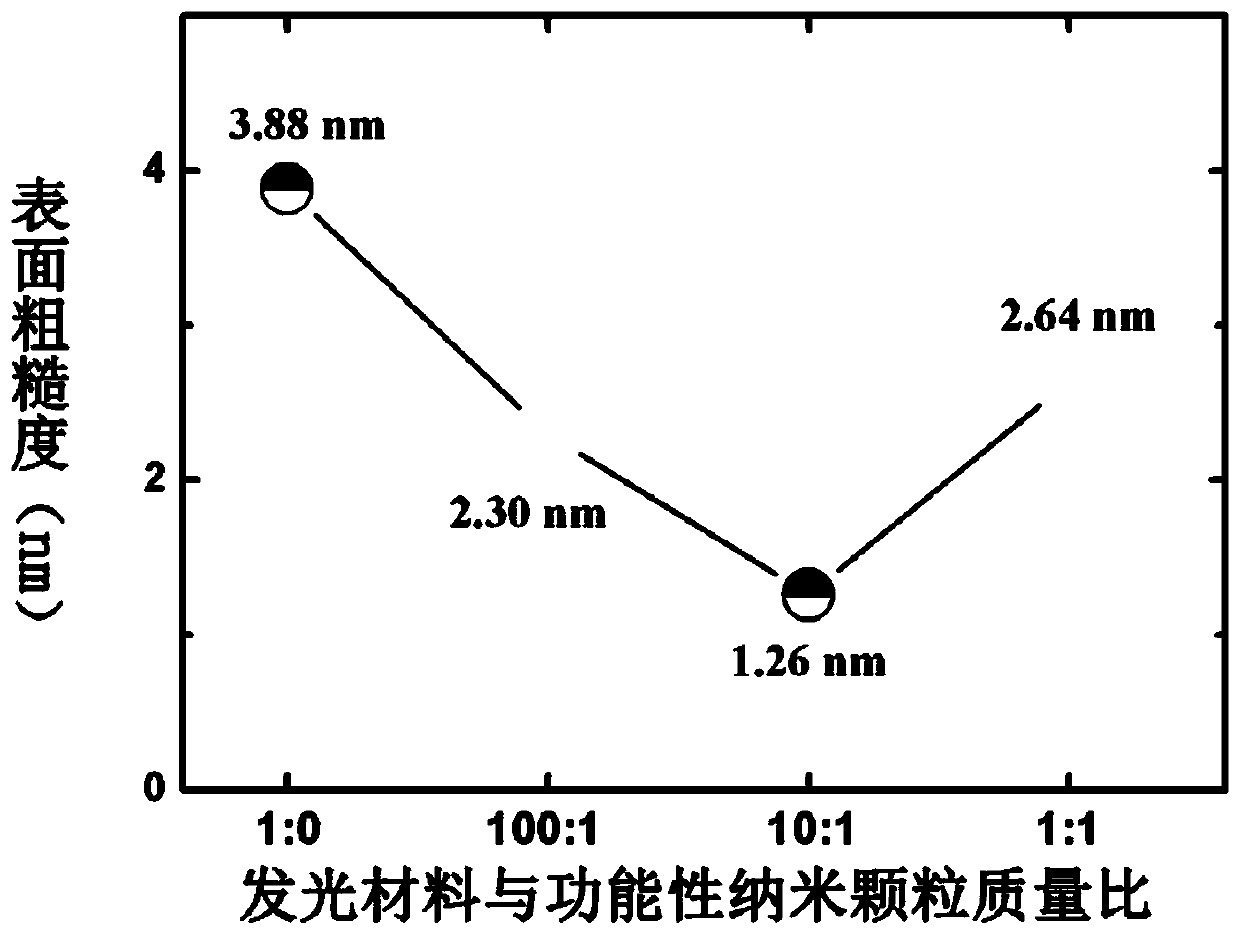

[0024] The first step: dissolve polyethylene oxide, ethoxylated trimethylolpropane triacrylate, lithium trifluoromethanesulfonate, and carbon quantum dots in a binary solvent with a volume ratio of cyclohexanone and tetrahydrofuran of 3:1 In, the solution concentration is 10mgmL -1 . Subsequently, 0.2 mL of polyethylene oxide solution prepared above, 1 mL of ethoxylated trimethylolpropane triacrylate solution, 0.2 mL of lithium trifluoromethanesulfonate solution, and 0.1 mL of carbon quantum dot solution were added to 10 mg of poly[ 2-Methoxy-5-(2'-ethyl-ethoxy)-1,4-styrene luminescent material was further dissolved with 0.5 mL of the above-mentioned binary solvent, stirred overnight at 80°C with 0.22 um's organic filter to form printing ink.

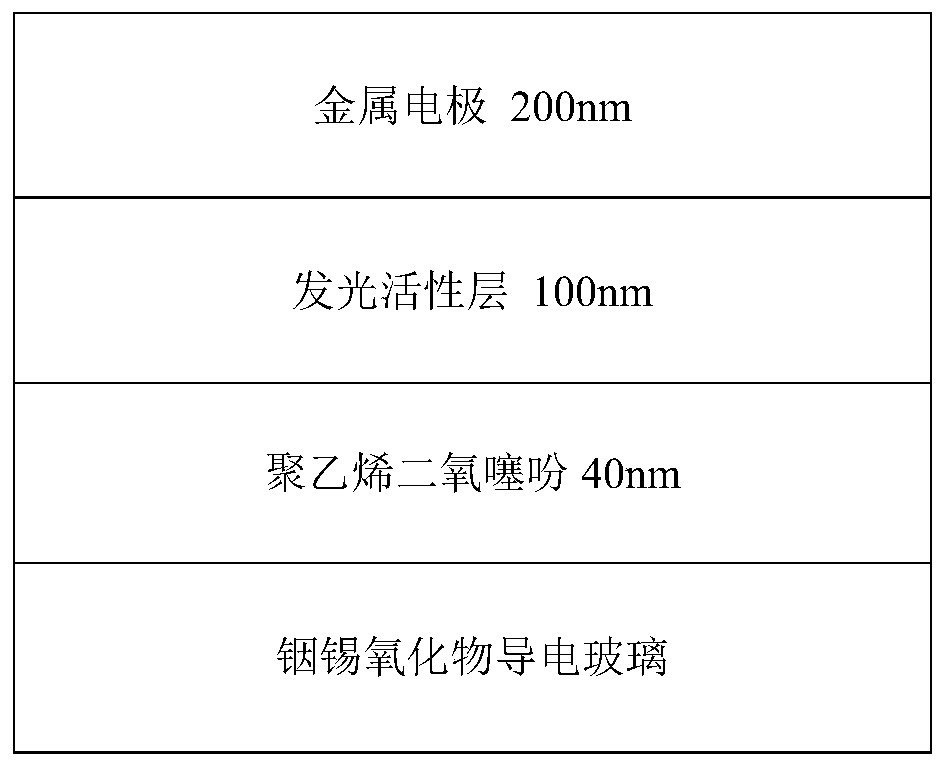

[0025] Step 2: The indium tin oxide substrate is subjected to plasma treatment for 5 minutes, and a 40nm thick polyethylene dioxythiophene film is printed on it, at a printing speed of 20m s -1 Under certain conditions, the ink was p...

Embodiment 2

[0029] The first step: dissolve polyethylene oxide, ethoxylated trimethylolpropane triacrylate, lithium trifluoromethanesulfonate, and carbon quantum dots in a binary solvent with a volume ratio of cyclohexanone and tetrahydrofuran of 3:1 In, the solution concentration is 10mg mL -1 . Subsequently, 0.2 mL of polyethylene oxide solution prepared above, 1 mL of ethoxylated trimethylolpropane triacrylate solution, 0.2 mL of lithium trifluoromethanesulfonate solution, and 0.01 mL of carbon quantum dot solution were added to 10 mg of poly[ 2-methoxy-5-(2'-ethyl-ethoxy)-1,4-styrene luminescent material was further dissolved with 0.59 mL of the above-mentioned binary solvent, stirred overnight at 80°C with 0.22 um's organic filter to form printing ink.

[0030] Step 2: The indium tin oxide substrate is subjected to plasma treatment for 5 minutes, and a 40nm thick polyethylene dioxythiophene film is printed on it, at a printing speed of 20m s -1 Under certain conditions, the ink wa...

Embodiment 3

[0034] The first step: dissolve polyethylene oxide, ethoxylated trimethylolpropane triacrylate, lithium trifluoromethanesulfonate, and carbon quantum dots in a binary solvent with a volume ratio of cyclohexanone and tetrahydrofuran of 3:1 In, the solution concentration is 10mg mL -1 . Subsequently, 0.2 mL of polyethylene oxide solution prepared above, 1 mL of ethoxylated trimethylolpropane triacrylate solution, 0.2 mL of lithium trifluoromethanesulfonate solution, and 0.1 mL of carbon quantum dot solution were added to 10 mg of poly[ {2,5-bis(3',7'-dimethyloctyloxy)-1,4-phenylethynyl}-co-{3-(4'-(3",7"-dimethyloctyloxy base)phenyl)-1,4-phenylacetylene}-co-{3-(3'-(3",7"-dimethyloctyloxy)phenyl)-1,4-phenylacetylene}] luminescence The material was further dissolved with 0.5mL of the above-mentioned binary solvent, stirred overnight at 80°C and then filtered with a 0.22um organic filter to form a printing ink.

[0035] Step 2: The indium tin oxide substrate is subjected to plasm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com