Preparation method and application of fireproof antibacterial cardboard

An antibacterial card, fireproof layer technology, applied in special paper, fireproofing agent addition, papermaking and other directions, can solve the problems of human safety that is still in question, harmful to human health, poor heat resistance, etc., and achieves safe and harmless raw materials and safe ingredients. Harmless, good paint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Slowly add 60 parts of red phosphorus and 40 parts of aluminum hydroxide to 150 parts of oxidized dextrin solution at room temperature, and stir for 20 minutes at 7500 rpm with a high-speed mixer to obtain a dispersion mixture of wall material and core material;

[0035] Prepare 2250 parts of simethicone oil and heat it to 75-85°C, slowly add the obtained wall material and core material dispersion mixture into the simethicone oil, and add 3.5 parts of cocamidopropyl betaine; then use a high-speed mixer Stir at 1500rpm, adjust the pH value between 3 and 5, and gradually cool the solution to room temperature within 30min, adjust the speed to 125rpm and continue stirring for 10min to obtain a microcapsule suspension;

[0036] The resulting microcapsule suspension was filtered and separated, the filter cake was washed with an aqueous solution of cocamidopropyl betaine, and dried in a drying oven at 75°C to obtain microcapsules; then 450 parts of ethanol was added to obtain t...

Embodiment 2

[0042] Slowly add 65 parts of red phosphorus and 35 parts of magnesium hydroxide to 145 parts of phenolic resin pre-condensed body at room temperature, and use a high-speed mixer to stir at 7500 rpm for 20 minutes to obtain a dispersion mixture of wall material and core material;

[0043] Prepare 2300 parts of simethicone oil and heat it to 75-85°C, slowly add the obtained wall material and core material dispersion mixture into the simethicone oil, and add 3.5 parts of cocamidopropyl betaine; then use a high-speed mixer Stir at 1500rpm, adjust the pH value between 3 and 5, and gradually cool the solution to room temperature within 30min, adjust the speed to 125rpm and continue stirring for 10min to obtain a microcapsule suspension;

[0044] The resulting microcapsule suspension was filtered and separated, the filter cake was washed with an aqueous solution of cocamidopropyl betaine, and dried in a drying oven at 75°C to obtain microcapsules; then 460 parts of ethanol was added ...

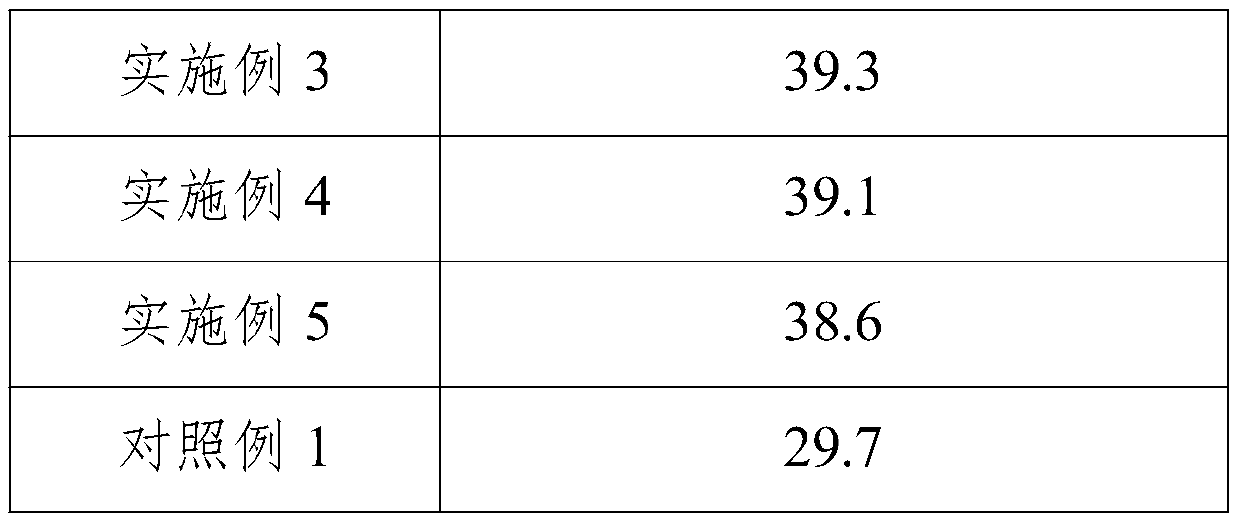

Embodiment 3

[0050] Slowly add 55 parts of red phosphorus and 45 parts of graphite into 145 parts of polyimide precondensed body at room temperature, and stir for 20 minutes at 7500 rpm with a high-speed mixer to obtain a dispersion mixture of wall material and core material;

[0051] Prepare 2250 parts of simethicone oil and heat it to 75-85°C, slowly add the obtained wall material and core material dispersion mixture into the simethicone oil, and add 3 parts of cocamidopropyl betaine; then use a high-speed mixer Stir at 1500rpm, adjust the pH value between 3 and 5, and gradually cool the solution to room temperature within 30min, adjust the speed to 125rpm and continue stirring for 10min to obtain a microcapsule suspension;

[0052] The resulting microcapsule suspension was filtered and separated, the filter cake was washed with an aqueous solution of cocamidopropyl betaine, and dried in a drying oven at 75°C to obtain microcapsules; then 450 parts of ethanol was added to obtain the micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com