High-end bearing steel material for machine tool and production process thereof

A production process and bearing steel technology, applied in the field of high-end bearing steel materials and production processes for machine tools, can solve the problems of wear resistance and contact fatigue strength that cannot meet the requirements of high-end CNC machine tools, and achieve uniform carbide distribution and carbonization. The effect of improving the material level and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

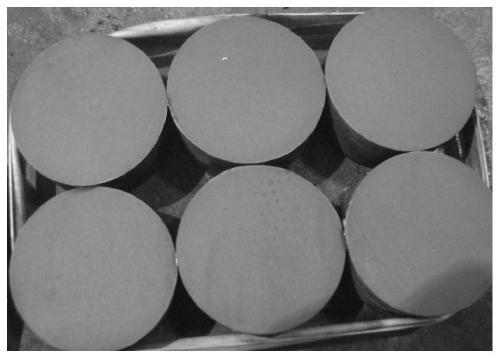

Image

Examples

Embodiment 1

[0050] This embodiment provides a high-end bearing steel material for machine tools, the chemical components contained in it include C: 0.95-1.05%, Si: 0.15-0.35%, Mn: 0.25-0.45%, Cr: 1.45- 1.60%, Ni: 0.05~0.10%, Mo: 0.02~0.06%, Al: 0.010~0.050%, Cu: 0.06~0.10%, P≤0.010%, S≤0.008%, Nb: 0.010~0.045%, Y≤ 0.020%, Ce≤0.010%, Ti≤0.0015%, O≤0.0020%, As≤0.040%, Sn≤0.030%, Sb≤0.0050%, Pb≤0.0020%, Ca≤0.0010%, the rest is Fe and unavoidable impurities .

[0051] Carbon is an important element that affects the performance of steel, and is one of the important elements to ensure that bearing steel can have sufficient hardenability, hardness and wear resistance. The carbon strengthening effect is very high, the carbon content in the steel increases, the yield point and tensile strength increase, but the toughness is significantly reduced. In order to improve the safety and reliability of the bearing steel, while increasing the carbon, through alloying Improve the strength, that is, from ...

Embodiment 2

[0060] This embodiment provides a production process of high-end bearing steel materials for machine tools. The production process includes electric furnace → LF refining and VD process → die casting → hot delivery / cover cooling → primary heating and rolling blanking → slow cooling → two Secondary heating and rolling → spheroidizing annealing;

[0061] In the electric furnace process:

[0062] Put pig iron, molten iron or steel material into the electric furnace, when the temperature of the molten steel is ≥1580°C and the C content is ≥0.30%, the generated oxidized slag is released, and the electric furnace begins to tap steel. New composite slag, aluminum ingot, alloy and lime;

[0063] In the LF refining and VD process:

[0064] After the molten steel reaches the refining position, the temperature is raised to 1550°C, and ferrosilicon and new composite slag are added to form slag. After the slag is melted, diffusion deoxidizer is added in batches for slagging. When the sla...

Embodiment 3

[0074] The difference between this embodiment and Embodiment 2 is only that in the electric furnace process of the production process of high-end bearing steel materials for machine tools in this embodiment:

[0075]Put pig iron, molten iron or iron and steel materials into the electric furnace according to the weight ratio of 4:6, and the iron and steel materials use non-Ti-containing steel grade materials; when the molten steel temperature is ≥ 1580 °C and the C content is ≥ 0.30%, the oxidation slag is released, and start Electric furnace tapping, the amount of steel remaining in the electric furnace is more than 7 tons during the tapping process, to prevent the oxidation slag from being carried out during the tapping process, if the oxidation slag is brought in during the tapping process, the FeO, P in the oxidation slag 2 o 5 、TiO 2 It will be reduced to P and Ti during the refining process, resulting in the return of phosphorus and titanium in the molten steel, so it mu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com