Environment-friendly self-repairing lubricating grease and preparation method thereof

A self-repairing and lubricating grease technology, applied in the field of lubricating grease, can solve the problems of equipment downtime, labor, waste, dryness, etc., and achieve good elasticity and flexibility, good extreme pressure and anti-wear properties, and good chemical stability.

- Summary

- Abstract

- Description

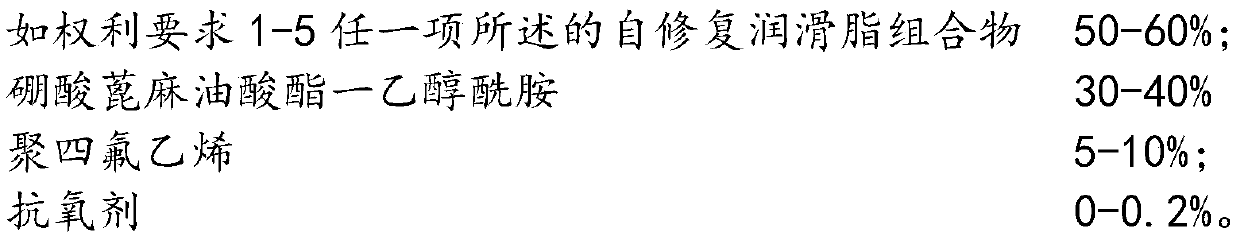

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1: Weigh 929.26g (1mol) of castor oil, 174.11g (1.5mol) of maleic acid, and 5.5g of neodymium oxide and add them into the reaction kettle together, stir and heat to 200°C, fully react for 3 hours, and discharge the water under reduced pressure;

[0035] Step 2: When the temperature is lowered to 100° C., add 1.5 g of the introduction agent lauroyl peroxide, continue to stir and fully react for 10 hours, and the self-healing grease composition is obtained. It can be directly used as environmentally friendly self-repairing grease.

[0036] Apply the environmentally friendly self-repairing grease prepared in this example on the guide rail of a multi-functional drilling and milling machine (model: ZXTM-40) (the guide rail of the equipment was originally lubricated with a certain brand of 0# grease, because the guide rail has been used for a period of time, wear and tear, The jitter is large and the noise is obvious. After cleaning the original used grease and applying ...

Embodiment 2

[0038] Step 1: Weigh 929.26g (1mol) of castor oil, 139.28g (1.2mol) of fumaric acid, and 1.5g of neodymium oxide into the reaction kettle together, stir and heat to 180°C, fully react for 4 hours, and discharge the water under reduced pressure;

[0039] Step 2: When the temperature is lowered to 120° C., add 0.7 g of introducing agent tert-butyl hydroperoxide, continue to stir and fully react for 8 hours, and the self-healing grease composition is obtained.

[0040] Weigh 500g of self-repairing grease composition, 400g of boric acid ricinoleate monoethanolamide, and 100g of polytetrafluoroethylene at a temperature of 60°C. After stirring for 30 minutes, put it into a homogenizer and homogenize for about 30 minutes. An environmentally friendly self-healing grease.

[0041] The preparation method of above-mentioned boric acid ricinoleate monoethanolamide:

[0042] Step 1: Weigh 298.46 g (1 mol) of ricinoleic acid and 61.08 g (1 mol) of monoethanolamine and add them together int...

Embodiment 3

[0045] Step 1: Weigh 929.26g (1mol) of castor oil, 116.07g of maleic acid (1mol), and 2.5g of neodymium oxide into the reaction kettle together, stir and heat to 190°C, fully react for 3.5 hours, and discharge the water under reduced pressure;

[0046] Step 2: When the temperature was lowered to 110° C., 1 g of the introducing agent perazobisisobutyronitrile was added, and the stirring was continued to fully react for 9 hours, and the self-healing grease composition was obtained.

[0047] Weigh 600g of self-repairing grease composition, 300g of boric acid ricinoleic acid ester monoethanolamide, 98g of polytetrafluoroethylene, and 2g of antioxidant (Irganox L57). Homogenizing in a quality machine for about 30 minutes is an environmentally friendly self-repairing grease.

[0048] The preparation method of above-mentioned boric acid ricinoleate monoethanolamide:

[0049] Step 1: Weigh 298.46 g (1 mol) of ricinoleic acid and 30.54 g (0.5 mol) of monoethanolamine into a blender, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com