Light stabilizer for weather-resistant polyvinyl chloride (PVC) material, and preparation method and application thereof

A technology of polyvinyl chloride and light stabilizer, which is applied in the direction of organic chemistry, can solve the problems of limiting the scope of use of polyvinyl chloride, poor light resistance, etc., achieve improved thermal stability, less environmental and human hazards, and realize industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

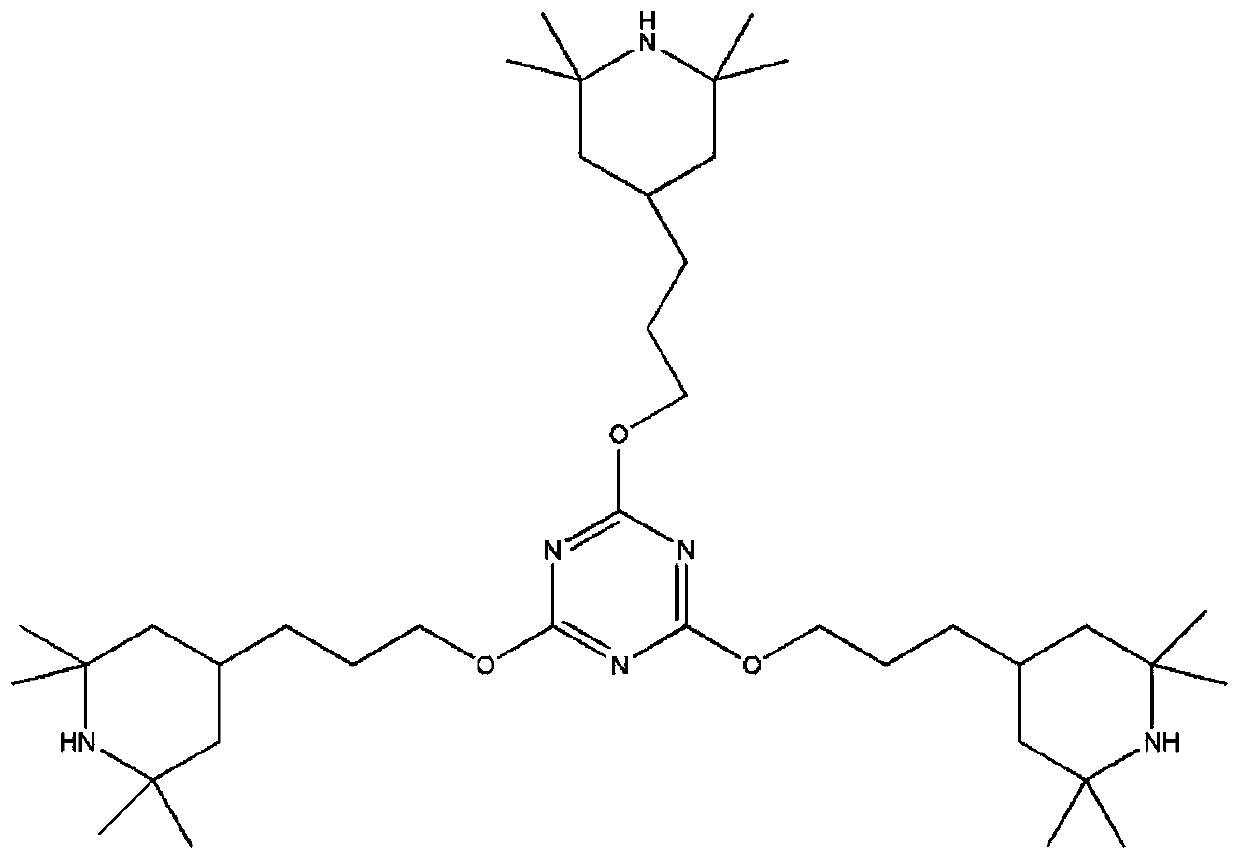

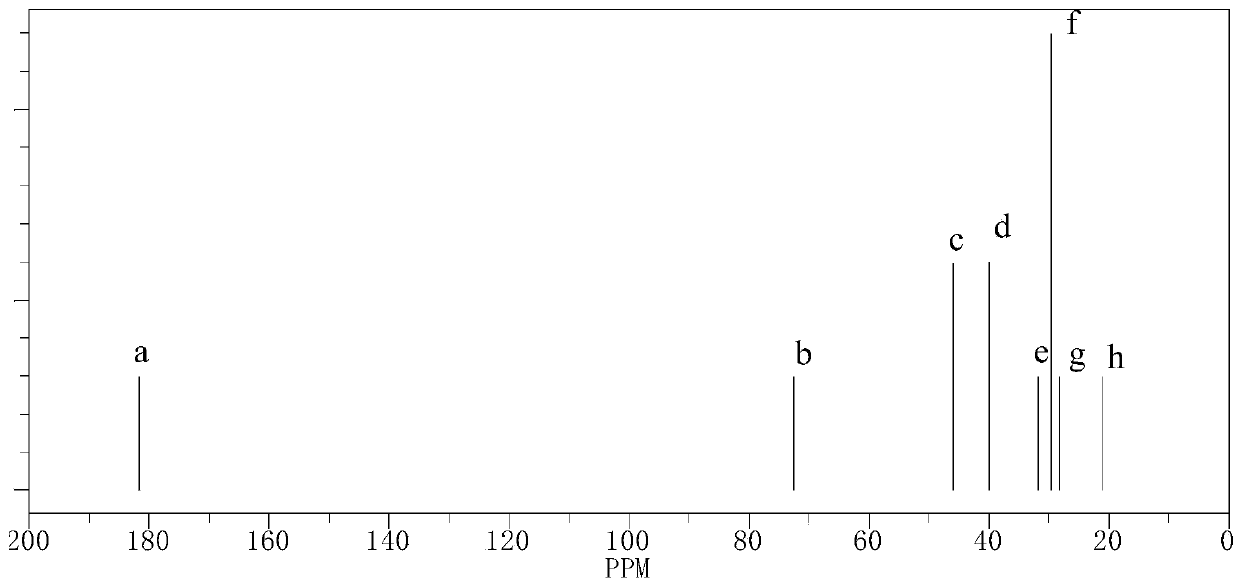

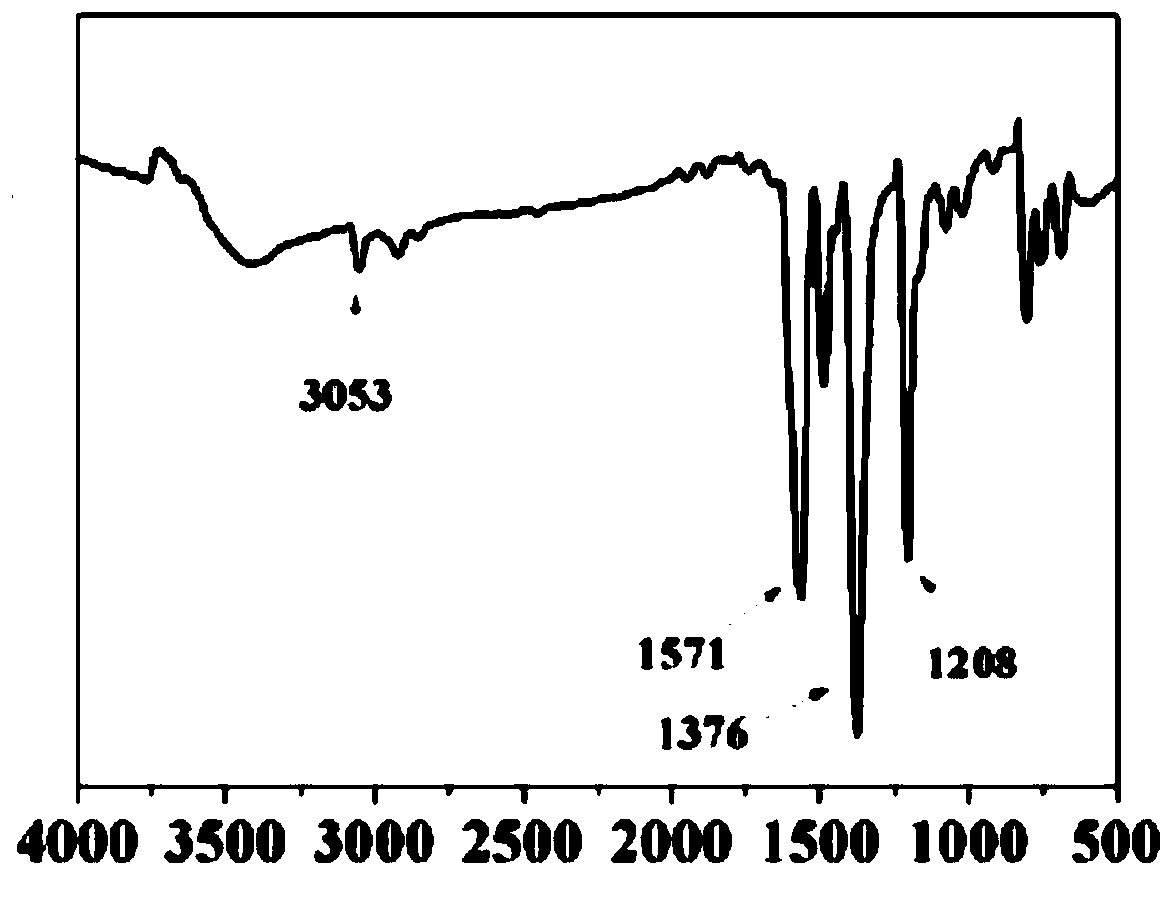

[0033] Step 1: Weigh 1.845g (0.01mol) of cyanuric chloride and 4.42g (0.032mol) of potassium carbonate into a 100ml three-neck flask, add an appropriate amount of tetrahydrofuran solvent to dissolve, heat up to 65°C under magnetic stirring, and dissolve 6.82g in 20ml of tetrahydrofuran (0.032mol) 2,2,6,6-methylpiperidine-4-n-propyl alcohol and the dropping funnel, drop it slowly within 30min, react at a constant temperature of 70°C for 6h, wait for the reaction solution to cool to room temperature, The crude product was obtained by suction filtration, washed several times with hot water at 80°C, and dried in an oven at 60°C overnight. The target product 2,4,6-tris[2-(2,2,6,6-tetramethylpiperidine)-propoxy]-1,3,5-triazine was obtained.

[0034] According to the thermogravimetric analysis, the decomposition temperature of the target product 2,4,6-tris[2-(2,2,6,6-tetramethylpiperidine)-propoxy]-1,3,5-triazine is 280°C, which is much higher than the processing of PVC in the prese...

Embodiment 2

[0044] Step 1: Weigh 1.845g (0.01mol) of cyanuric chloride and 4.55g (0.033mol) of potassium carbonate in a 100ml three-neck flask, add an appropriate amount of tetrahydrofuran solvent to dissolve, heat up to 70°C under magnetic stirring, and dissolve 7.27g in 25ml of tetrahydrofuran (0.032mol) 2,2,6,6-methylpiperidine-4-n-butyl alcohol and the dropping funnel, drop it slowly within 20min, react at a constant temperature of 80°C for 7h, wait for the reaction solution to cool to room temperature, The crude product was obtained by suction filtration, washed several times with hot water at 80°C, and dried in an oven at 60°C overnight. The target product 2,4,6-tris[2-(2,2,6,6-tetramethylpiperidine)-butoxy]-1,3,5-triazine was obtained.

[0045] MS: m / z=686.5

[0046] Elemental analysis: C, 69.93%; H, 10.86%; N, 12.23%; O, 6.99%

[0047] Step 2: Tin methyl mercaptide, rare earth stabilizer xt-1 (Shandong Youso Chemical Technology Co., Ltd.), calcium zinc stabilizer G-30 (Guangzhou...

Embodiment 3

[0050] Step 1: Weigh 1.845g (0.01mol) of cyanuric chloride and 4.42g (0.032mol) of potassium carbonate into a 100ml three-neck flask, add an appropriate amount of tetrahydrofuran solvent to dissolve, heat up to 70°C under magnetic stirring, and dissolve 8.2g in 20ml of tetrahydrofuran (0.034mol) 2,2,6,6-methylpiperidine-4-n-pentyl alcohol and the dropping funnel, slowly drop it within 30min, react at a constant temperature of 80°C for 8h, and wait for the reaction solution to cool to room temperature, The crude product was obtained by suction filtration, washed several times with hot water at 80°C, and dried in an oven at 60°C overnight. The target product 2,4,6-tris[2-(2,2,6,6-tetramethylpiperidine)-pentyloxy]-1,3,5-triazine was obtained.

[0051] MS: m / z=700.5

[0052] Elemental analysis: C, 70.24%; H, 10.93%; N, 11.99%; O, 6.85%

[0053] Step 2: Tin methyl mercaptide, rare earth stabilizer xt-1 (Shandong Youso Chemical Technology Co., Ltd.), calcium zinc stabilizer G-30 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com