Method for preparing foam material by microwave hydrogel foaming

A foam material and microwave foaming technology, which is applied in the field of preparing foam materials by microwave foaming of hydrogel, achieves the effects of good versatility, low energy consumption, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

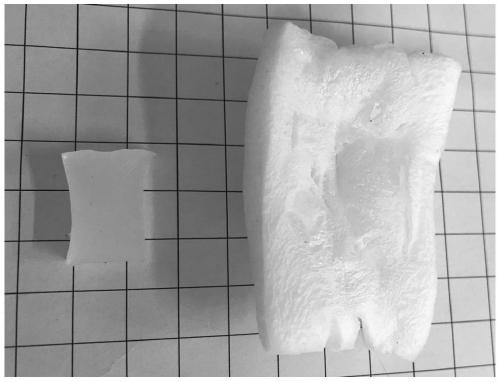

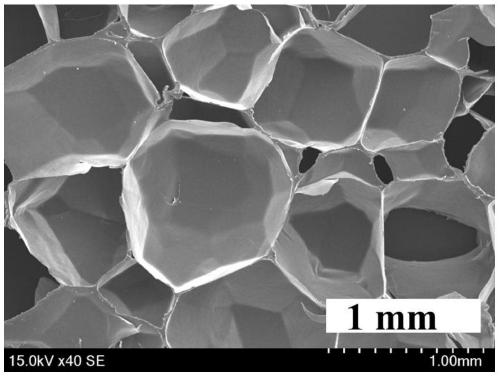

Embodiment 1

[0029] Disperse 1.2g lithium diatomite in 60.0g deionized water, then add 30.0g monomeric acrylamide to the lithium diatomaceous earth dispersion respectively, after stirring for 15min, add 10.0mL 20mg / mL initiator persulfuric acid respectively under ice-water bath Potassium KPS and 300.0 μL catalyst tetramethylethylenediamine TEMED, finally, transfer the solution into a square PE box, seal it and place it in a water bath at 10°C for polymerization for 48h to obtain a nanocomposite hydrogel, and dry the hydrogel To a water content of 25wt%, microwave foaming under the condition of microwave power 100W for 2min to obtain a gel-based foam with a foam density of 0.102g / cm 3 .

Embodiment 2

[0031]Disperse 1.2g lithium diatomaceous earth in 60.0g deionized water, then add 30.0g monomer acrylamide to the lithium diatomaceous earth dispersion respectively, after stirring for 15min, add 10.0mL 20mg / mL initiator persulfuric acid respectively under ice-water bath Potassium KPS and 300.0 μL catalyst tetramethylethylenediamine TEMED, finally, the solution was transferred to a square PE box, sealed and placed in a water bath at 10°C for polymerization for 48h to obtain a nanocomposite hydrogel, and the hydrogel was dried To a water content of 35wt%, microwave foaming under the condition of microwave power 100W for 2min to obtain a gel-based foam with a foam density of 0.87g / cm 3 .

Embodiment 3

[0033] Disperse 1.2g lithium diatomaceous earth in 60.0g deionized water, then add 30.0g monomer acrylamide to the lithium diatomaceous earth dispersion respectively, after stirring for 15min, add 10.0mL 20mg / mL initiator persulfuric acid respectively under ice-water bath Potassium KPS and 300.0 μL catalyst tetramethylethylenediamine TEMED, finally, the solution was transferred to a square PE box, sealed and placed in a water bath at 10 °C for polymerization for 48 h to obtain a nanocomposite hydrogel. Dry the hydrogel to a water content of 10wt%, microwave foaming under the condition of microwave power 100W for 2min, and obtain a gel-based foam with a foam density of 0.96g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com