Polypropylene sheet

A polypropylene and sheet technology, applied in the field of polypropylene plastics, can solve problems such as easy deformation of polypropylene, and achieve the effect of reducing lifespan and reducing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

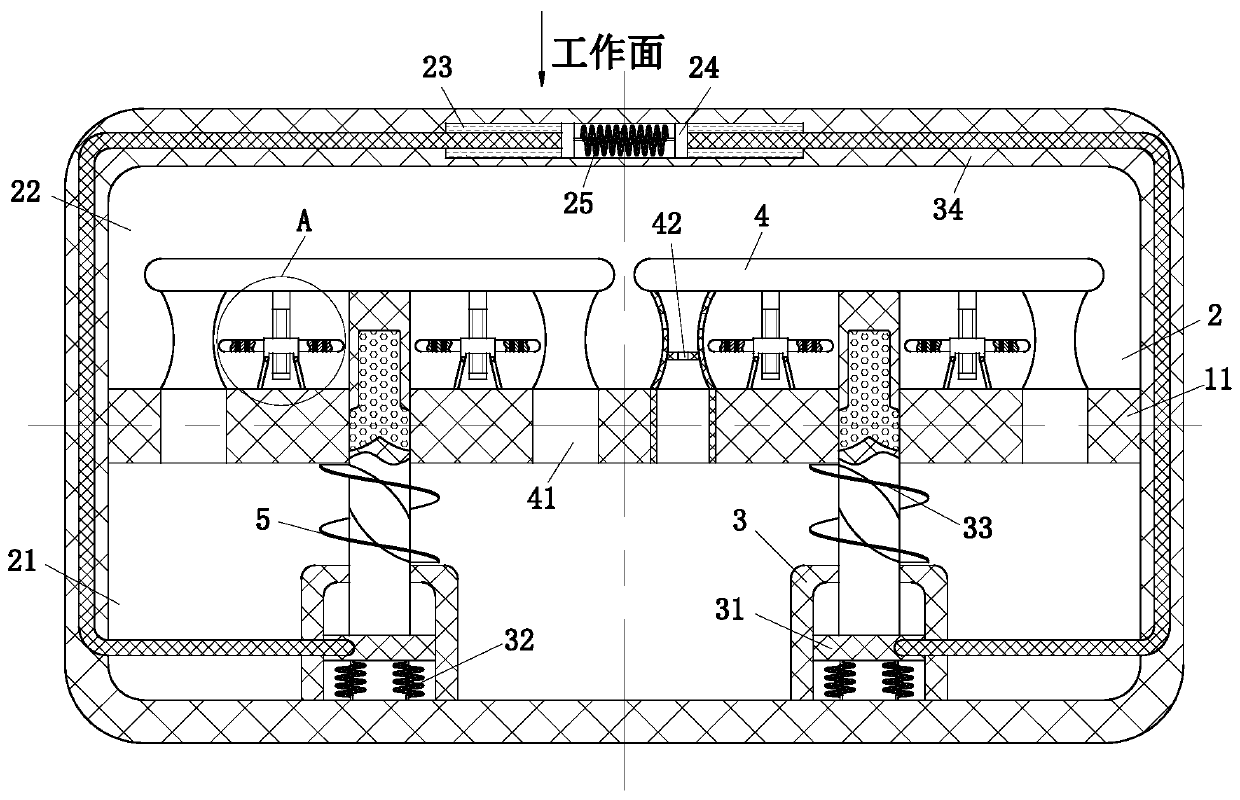

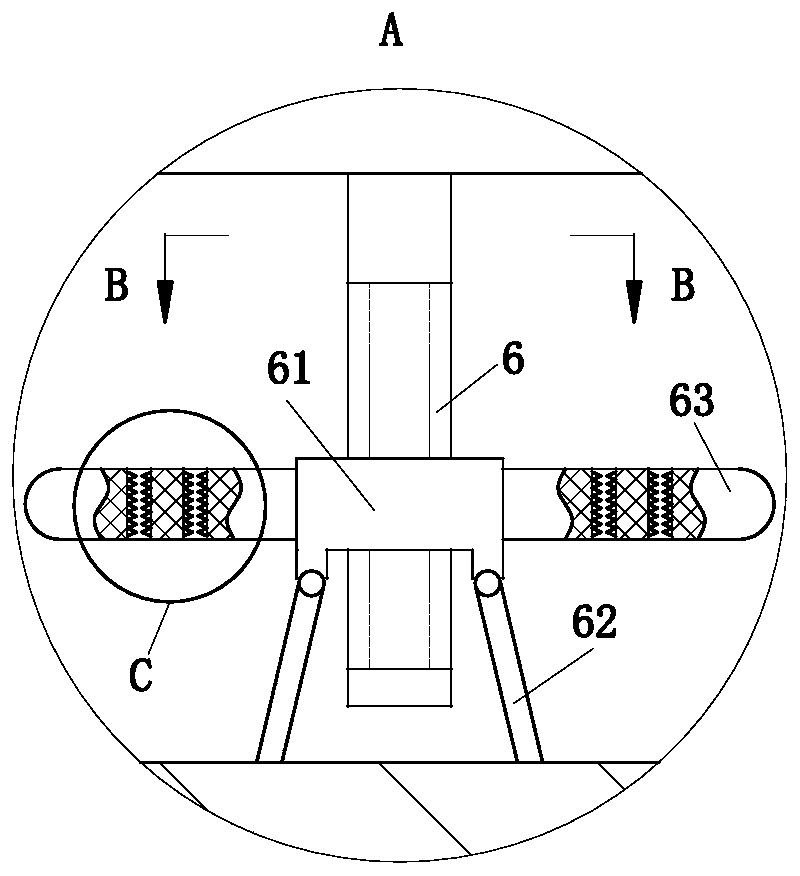

[0023]As a specific embodiment of the present invention, one end of the vertical plate 33 located in the second chamber 22 is fixedly connected with a moving plate 4, and the two sides below the moving plate 4 are fixedly connected with an airbag 41, and the airbag 41 is far away from the moving plate 4. One end of the airbag 41 runs through the horizontal plate 11, and air holes 42 are provided on both sides of the airbag 41. When the moving plate 4 moves up with the vertical plate 33, the airbag 41 stretches to bring the gas in the first chamber 21 into the second chamber 22; When the plate 33 moves up, it drives the moving plate 4 to move up. After the moving plate 4 moves up, the air bag 41 is stretched. After the air bag 41 is stretched, the gas in the first chamber 21 enters the second chamber through the air hole 42 on the air bag 41 In the chamber 22, because the eight-hydrate barium hydroxide crystal and the ammonium chloride crystal in the second chamber 22 react to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com