Deck tube bundle unit mounting method

An installation method and deck technology, applied in the direction of pipeline support, transportation and packaging, pipes/pipe joints/pipe fittings, etc., can solve the problems of frame deformation, affecting installation accuracy, etc., and achieve convenient installation and positioning, controllable installation accuracy, and convenient production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further illustrated below by means of examples, but the present invention is not limited thereto within the scope of examples.

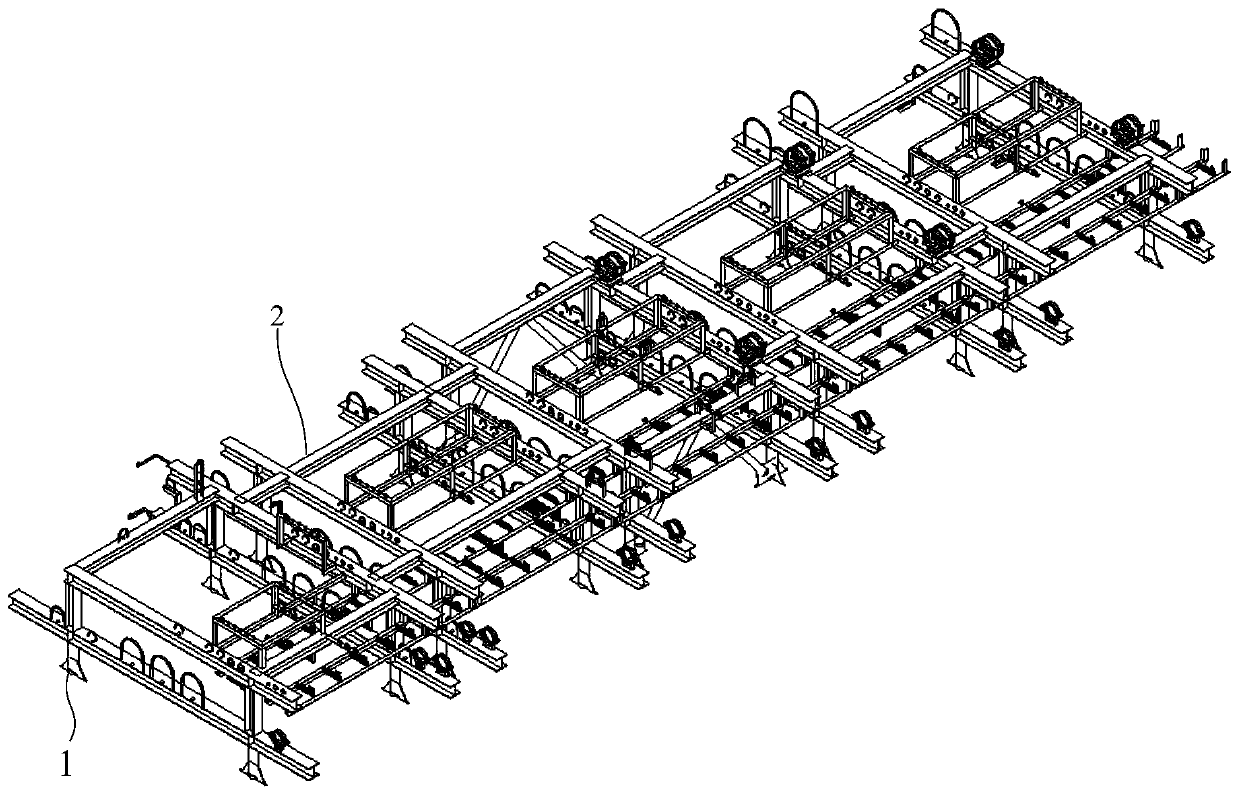

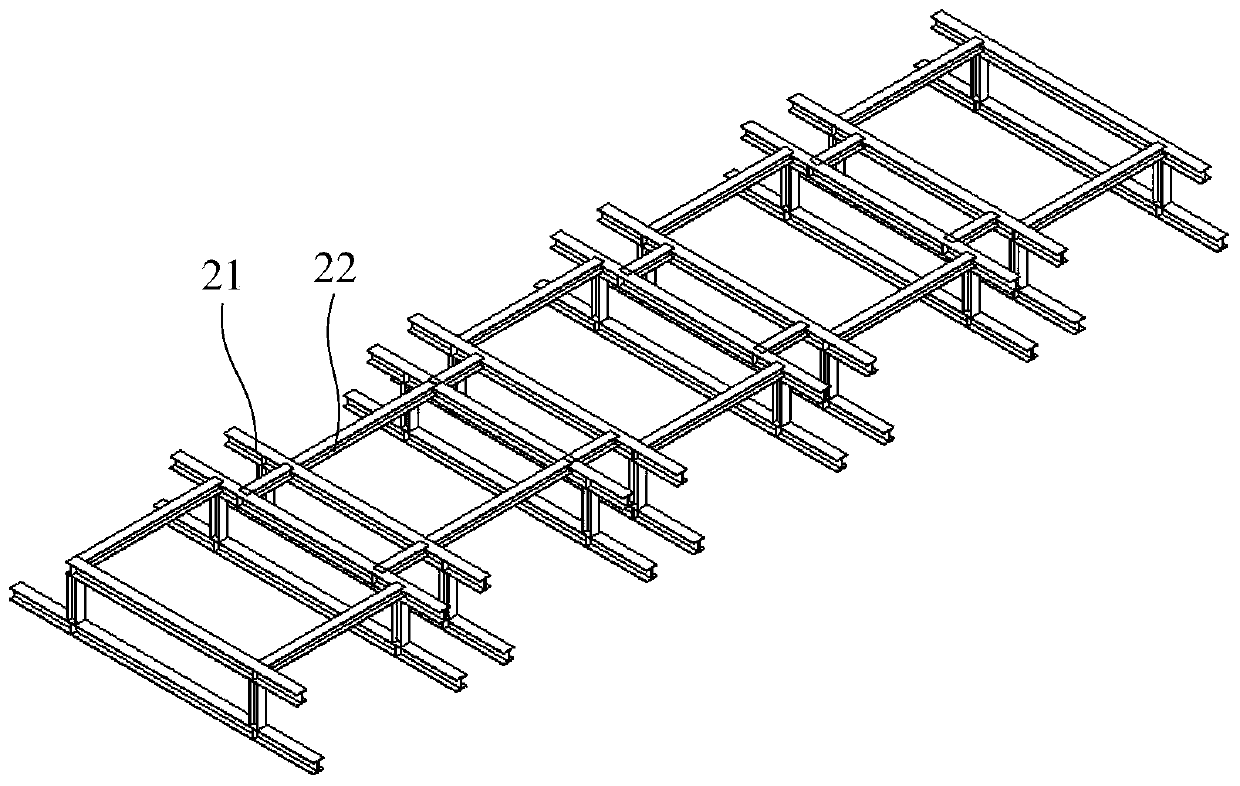

[0027] Such as figure 1 with figure 2 Shown, a kind of deck pipe bundle unit installation method of the present invention comprises the following steps:

[0028] S11. Mark the fixed position of the outrigger 1 at the installation position of the tube bundle unit on the deck. After fixing the outrigger 1 on the deck, use a bracket to connect the root of the outrigger 1 to the deck. Each outrigger 1 There are two brackets, which are arranged symmetrically, and the number of brackets can also be 3 or 4, which are evenly distributed and arranged in the circumferential direction of the leg 1;

[0029] S12. Weld the legs 1 of the tube bundle unit to the corresponding fixed position on the deck, level the top of the legs 1 uniformly, cut off the margin, and make the tops of the legs 1 on the same level;

[0030] S13 , hoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com