Large span cable bridge rack installation mold and installation method thereof

A cable bridge and large-span technology, which is applied in the direction of cable installation device, cable installation, electrical components, etc., can solve the problem that the large-span bridge cannot use the factory building driving and truck crane, so as to reduce manpower input and construction cost , The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

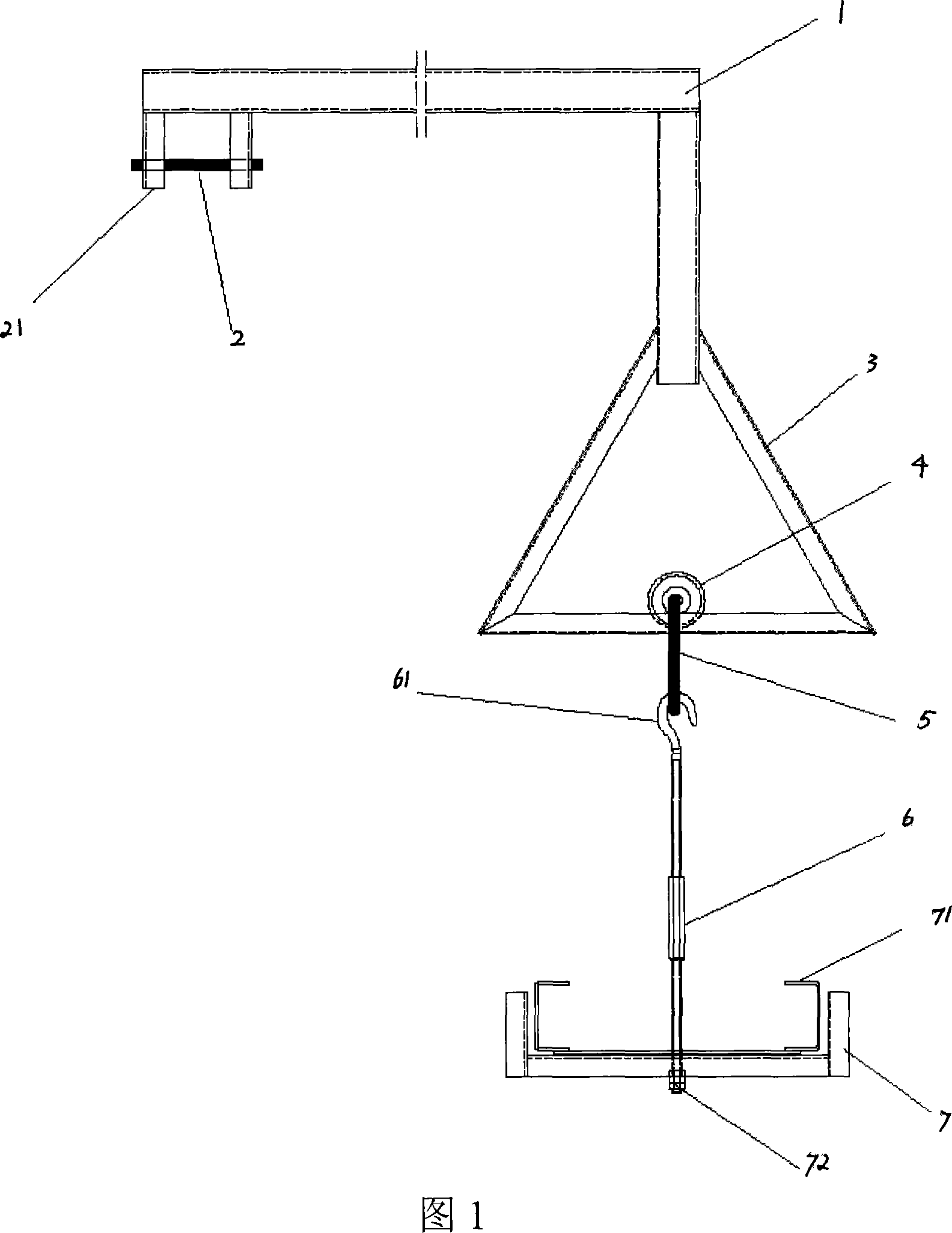

[0029] Such as figure 1 Shown: a long-span cable tray installation mold, which includes:

[0030] Right angle cantilever 1;

[0031] A bolt 2, the end of the horizontal side of the right-angled cantilever 1 is provided with a bolt bracket 21 oppositely arranged to support the bolt 2 horizontally;

[0032] A spreader sliding bracket 3, which is an isosceles triangle, its top is fixedly connected to the vertical edge of the right-angled cantilever 1, and its bottom edge has a U-shaped groove (not shown in the figure);

[0033] A bearing 4, which is arranged in the groove of the bottom edge of the said spreader sliding bracket 3 and can roll left and right; The clamping plate of above-mentioned bearing 4 (not shown in the figure);

[0034] A circular ring 5, which passes through the center of the bearing 4 and surrounds the bottom edge of the spreader sliding bracket 3;

[0035] A rigging turnbuckle 6, the top end of which includes a hook 61, and is hooked on the ring 5 by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com