A lightweight prefabricated composite wall

A prefabricated wall, lightweight technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of hanging and affecting the construction period, and achieve the effect of avoiding wet work, good fireproof and sound insulation performance, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

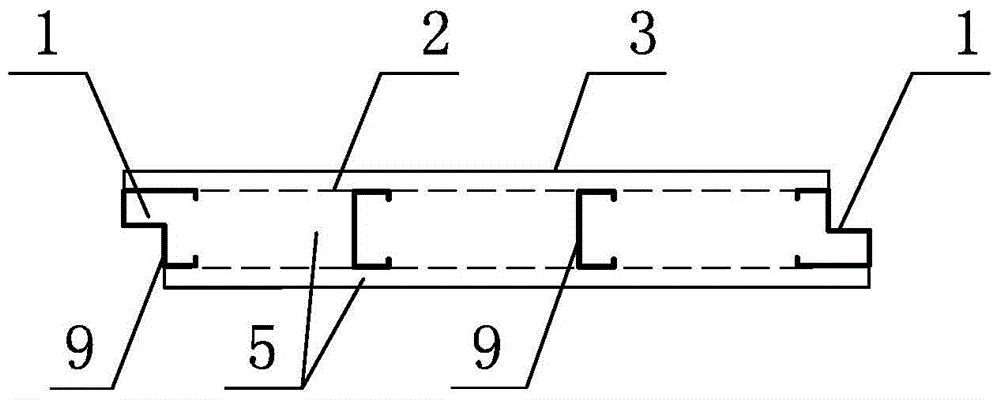

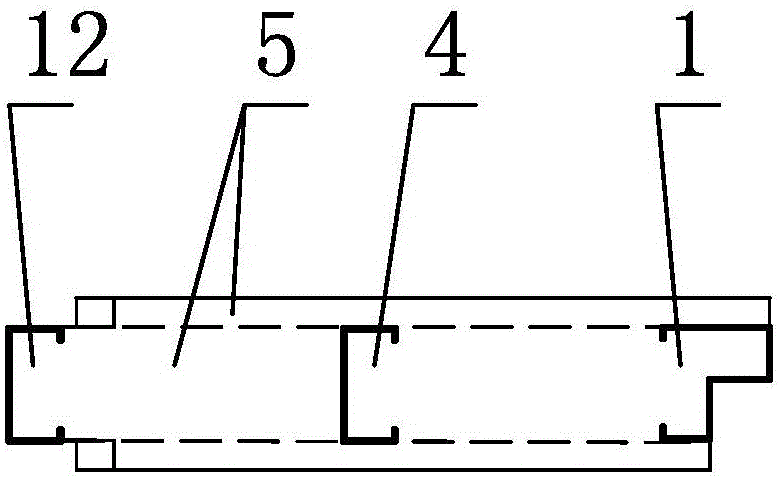

[0038] The present invention is further described below in conjunction with accompanying drawing and embodiment: described lightweight prefabricated composite wall body, such as Figure 11 As shown, it is composed of three kinds of light prefabricated wall sections 3 with the same composition, the cross-shaped wall is spliced through the transfer steel column 7, and the straight wall, L-shaped wall and T-shaped wall are directly spliced by bolts or self-tapping screws 8 Multi-segment lightweight prefabricated wall segment 3 of type wall.

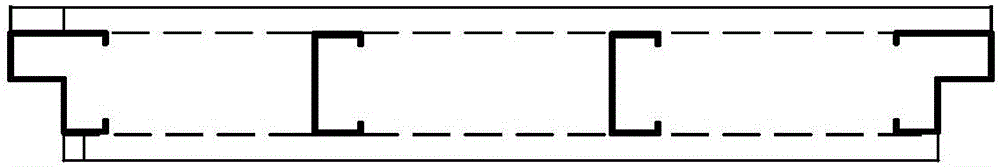

[0039] Such as figure 1 , 2, 3 are the horizontal section structures of three kinds of lightweight prefabricated wall sections 3, the lightweight prefabricated wall section 3 is a straight wall section as a whole, and consists of a plurality of vertically arranged steel wall columns 9, horizontally on the top of each steel wall column The connected upper guide rails 2 and the lower guide rails 10 connected horizontally on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com