High-pressure grinding roller installation construction technology

A high-pressure roller mill and construction process technology, applied in assembly machines, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult to guarantee installation quality, slow installation progress, complex construction process, etc., and achieve easy control of heating quality and installation. The effect of increasing error and ensuring assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

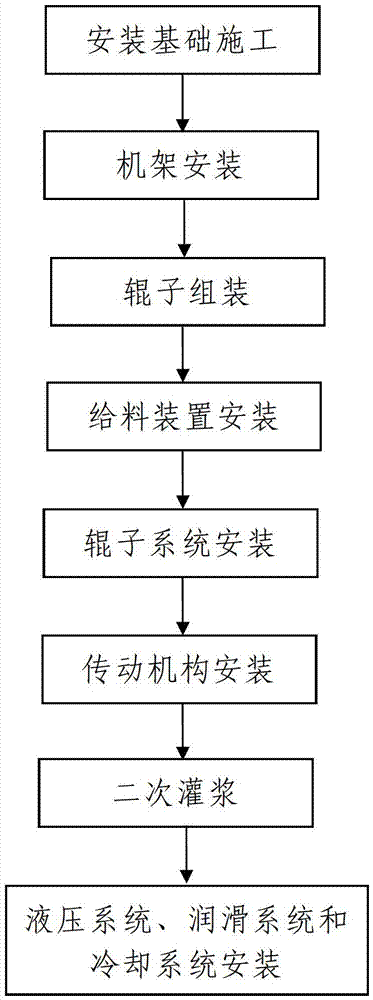

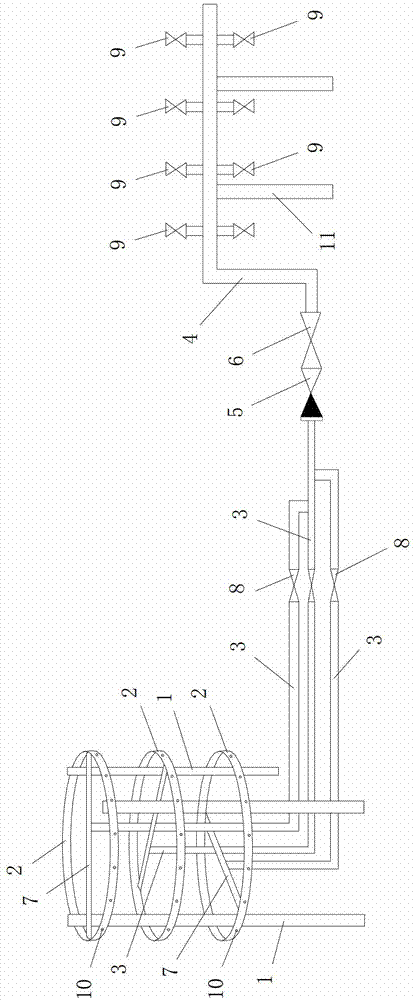

[0056] Such as figure 1 A high-pressure roller mill installation construction process is shown, the installed high-pressure roller mill includes a frame and a feeding device, a roller system, a lubrication system and a cooling system installed on the frame, and the roller system includes A moving roller and a fixed roller, and the frame is provided with a hydraulic system that drives the moving roller to slide back and forth, the moving roller is connected to the hydraulic system, and the moving roller and the fixed roller pass through the transmission mechanism Carry out transmission connection with the electric driving mechanism; the structure of the moving roller and the fixed roller is the same and both include a roller tire and a roller core coaxially sleeved in the roller tire. The installation and construction process of the high pressure roller mill includes the following step:

[0057] Step 1. Installation foundation construction: use concrete pouring to shape the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com