A kind of color double-sided antistatic polyester film and preparation method thereof

A polyester film, antistatic technology, applied in the field of color double-sided antistatic polyester film and its preparation, can solve the problems of short service life, decreased surface resistance of the film, detachment of the coating base film, etc., and achieves low humidity sensitivity. , Long service life and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

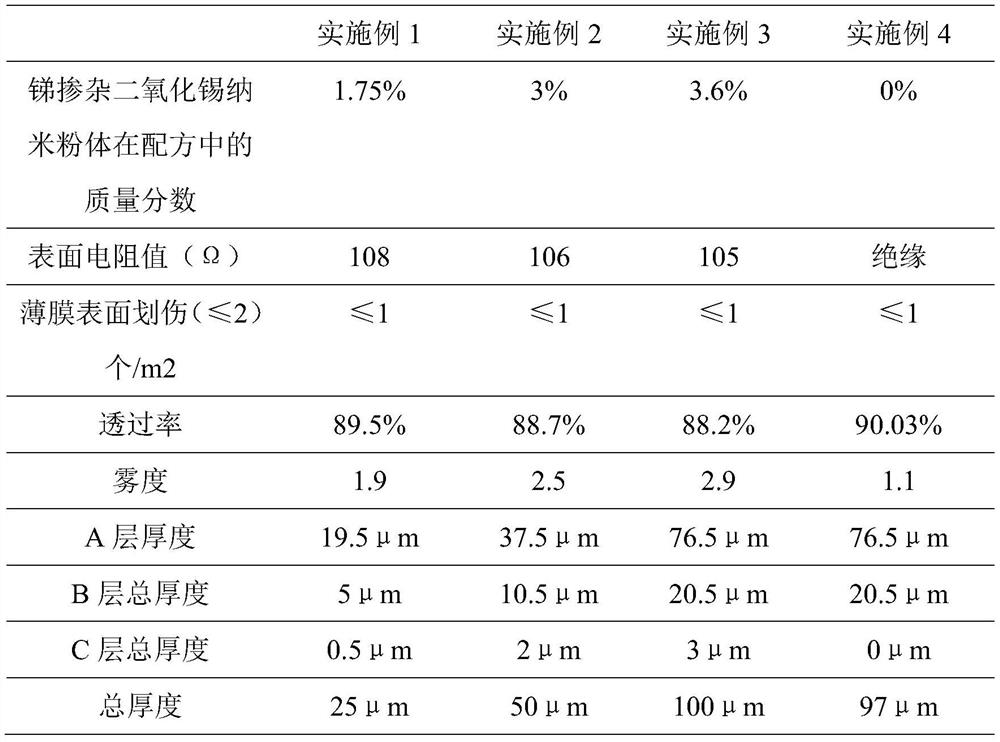

Embodiment 1

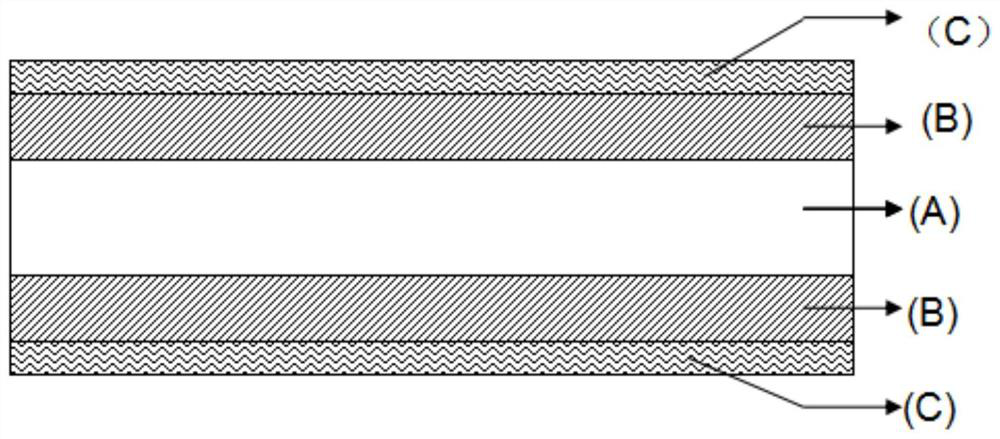

[0101] Color double-sided antistatic polyester film structure such as figure 1 Shown, preparation method comprises the following steps:

[0102] (1), the preparation of the antistatic coating, polyurethane resin, antimony-doped tin dioxide nano-powder, isopropanol, butanone and diphenyldimethoxysilane according to the weight ratio of 40:30 at normal temperature: 11:11:3 Stir evenly, set the stirring speed at 90r / min, stir continuously for 15min, prepare 5kg of antistatic stock solution, add 90kg of deionized water, 5kg of absolute ethanol, stir for 30min at a speed of 120r / min, and prepare antistatic Static paint spare;

[0103] (2), the polyester film is prepared by three-layer co-extrusion biaxial stretching equipment, the A-layer raw material (using lake blue color masterbatch, the added mass fraction is 5%, and the added mass fraction of Daguang PET particles is 95%) ) is sent to the corresponding silo of the main extruder through the suction system, the main extrusion v...

Embodiment 2

[0109] The preparation method of colored double-sided antistatic polyester film comprises the following steps:

[0110] (1), the preparation of the antistatic coating, polyurethane resin, antimony-doped tin dioxide nano-powder, isopropanol, butanone and diphenyldimethoxysilane according to the weight ratio of 45:30 at normal temperature: The ratio of 12:9:4 was added in the beaker and stirred evenly, and 10 kg of antistatic stock solution was prepared, 75 g of deionized water, 15 kg of absolute ethanol were added, and stirred at a speed of 120 r / min for 35 minutes to prepare an antistatic coating for later use;

[0111] (2), the polyester film is prepared by three-layer co-extrusion biaxial stretching equipment, and the A-layer raw material (using rose red color masterbatch, the added mass fraction is 2.5%, and the added mass fraction of Daguang PET particles is 97.5%) ) is sent to the corresponding silo of the main extruder through the suction system, the main extrusion volum...

Embodiment 3

[0116] (1), the preparation of the antistatic coating, polyurethane resin, antimony-doped tin dioxide nanopowder, isopropanol, butanone and diphenyldimethoxysilane according to weight ratio 50:25 at normal temperature: The ratio of 12:13:2 was added to the beaker in order to mix and stir evenly to prepare 15kg of antistatic stock solution, add 65kg of deionized water, 20kg of absolute ethanol, and stir for 40min at a speed of 120r / min to prepare an antistatic coating for later use;

[0117] (2), the polyester film is prepared by three-layer co-extrusion biaxial stretching equipment, and the A-layer raw material (using golden yellow color masterbatch, the added mass fraction is 1%, and the added mass fraction of Daguang PET particles is 99% ) is sent to the corresponding silo of the main extruder through the suction system, the main extrusion volume is 1050kg / h, the ratio of raw materials is controlled by a metering pump, melted and extruded at a high temperature of 285°C, and v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com