High-wettability sulfide-based composite electrolyte with 'sandwich' structure, and preparation method and application of high-wettability sulfide-based composite electrolyte

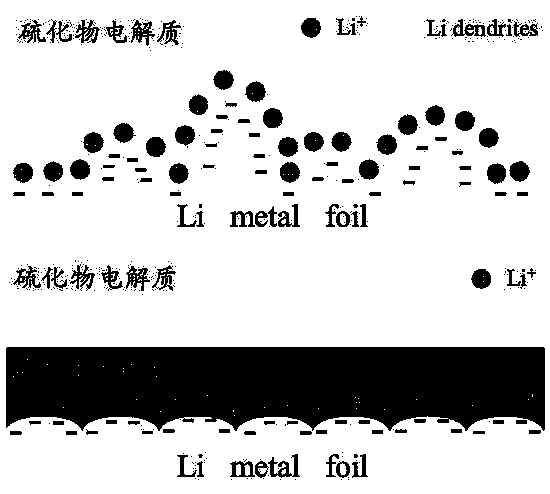

A composite electrolyte, high wettability technology, applied in composite electrolytes, solid electrolytes, non-aqueous electrolytes, etc., can solve the problems of poor sulfide interface contact, unstable sulfide electrolyte, low ionic conductivity, etc. Effects of improved electrochemical stability, improved wettability and compatibility, high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

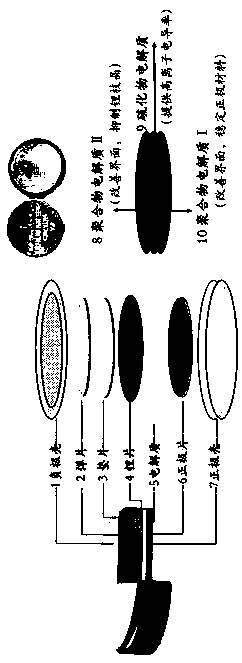

[0031] The preparation steps of the "sandwich" structure high wettability sulfide-based composite electrolyte provided in this example are as follows:

[0032] (1) Will Li 2 S and P 2 S 5 High-energy ball milling at a molar ratio of 70:30 to obtain Li with high ionic conductivity 7 P 3 S 11 sulfide solid electrolyte.

[0033] (2) The sulfide solid electrolyte obtained in step (1) was heat-treated at a high temperature of 240 °C for 1 h, and then ground to obtain a solid electrolyte powder.

[0034] (3) The solid electrolyte powder was pressed into a sulfide solid electrolyte sheet in a glove box.

[0035] (4) Dissolve polyvinylidene fluoride and lithium dioxalate borate LiBOB in an appropriate amount of acetonitrile solution at a molar ratio of 10:1, and stir at room temperature for 10 hours to obtain polymer electrolyte solution I.

[0036] (5) Combine polyvinylidene fluoride and lithium nitrate LiNO 3 Dissolve in an appropriate amount of acetonitrile solution at a mo...

Embodiment 2

[0039] (1) Will Li 2 S and P 2 S 5 According to the molar ratio of 75:25, high-energy ball milling was carried out to obtain Li with high ionic conductivity. 3 P.S. 4 sulfide solid electrolyte.

[0040] (2) The sulfide solid electrolyte obtained in step (1) was heat-treated at a high temperature of 260 °C for 1 h, and then ground to obtain a solid electrolyte powder.

[0041] (3) The solid electrolyte powder was pressed into a sulfide solid electrolyte sheet in a glove box.

[0042] (4) Polyethylene oxide and lithium difluorooxalate borate LiODFB were dissolved in an appropriate amount of acetonitrile solution at a molar ratio of 18:1, and stirred at room temperature for 24 hours to obtain polymer electrolyte solution I.

[0043] (5) Polyethylene oxide (PEO) and lithium nitrate LiNO 3 Dissolve in an appropriate amount of acetonitrile solution according to a molar ratio of 18:1, and stir at room temperature for 24 hours to obtain a polymer electrolyte solution .

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com