Sound insulation floor and manufacturing method thereof

A technology of sound insulation and floor slabs, which is applied in the field of sound insulation floor slabs and sound insulation floor slabs, and can solve problems such as floor surface cracking, inconvenience, and reduced floor sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

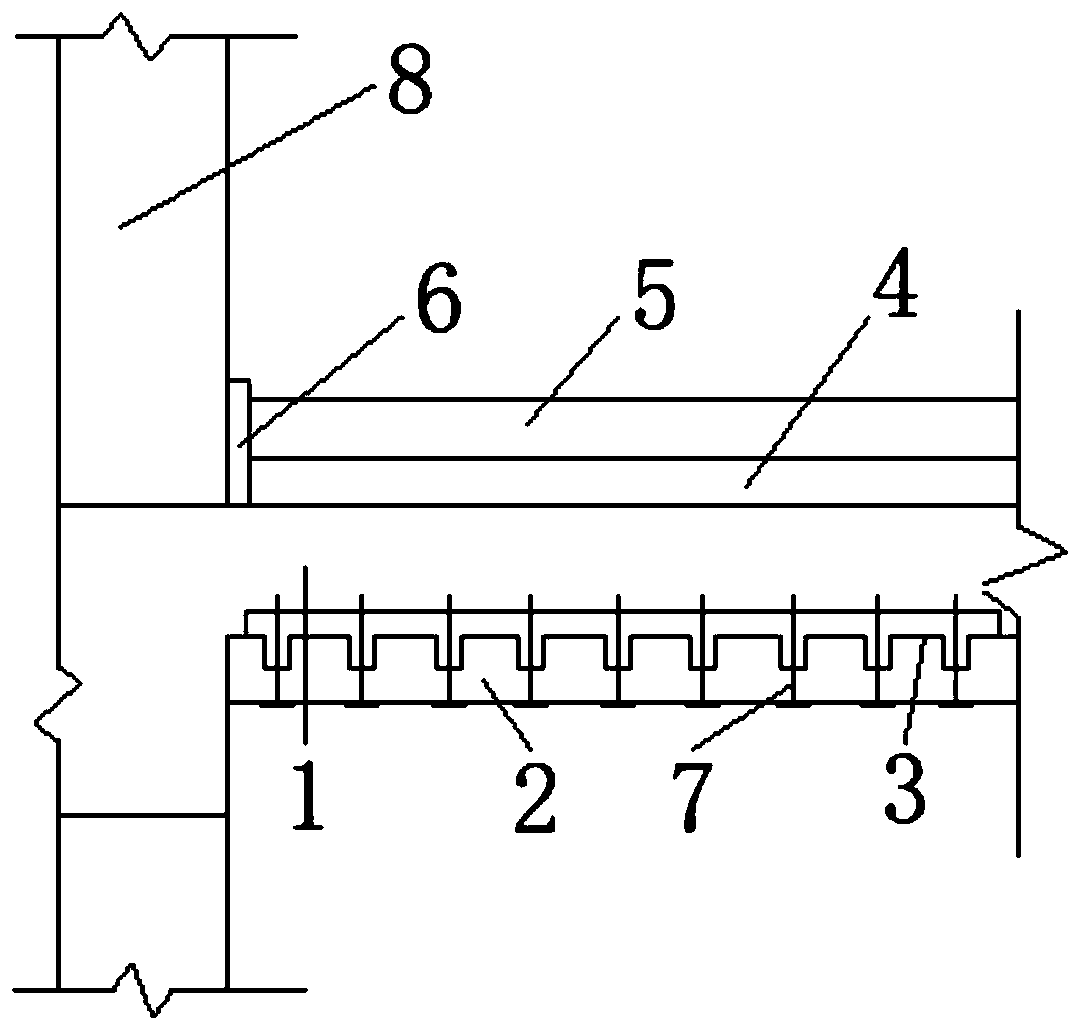

[0046] This embodiment provides as figure 1 A sound insulation floor is shown, which includes a concrete base 1, a sound insulation layer 2, a connecting bracket 3, a waterproof protection layer 4, a leveling layer 5, a vertical sound insulation sheet 6 and a ground decoration layer.

[0047] The sound insulation layer 2 in this embodiment is arranged on the side of the concrete base 1 away from the ground. It should be noted that the side away from the ground on the concrete base 1 refers to figure 1 The lower side of the concrete in the figure 1The top layer above constitutes the ground. The sound insulation layer 2 is composed of a sound insulation and sound absorption insulation board, and the sound insulation and sound absorption insulation board includes inorganic materials, organic materials and several cavities, wherein the inorganic materials wrap the organic materials, and the cavities are formed on the organic materials in the area wrapped by the inorganic materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com