Grinding process technology for casting aluminum-nickel-cobalt magnetic steel

A grinding process, AlNiCo technology, applied in the direction of manufacturing tools, grinding workpiece supports, metal processing equipment, etc., can solve the problems of large consumption of grinding wheels, poor cutting ability, low dimensional accuracy, etc., to achieve high processing efficiency, grinding The effect of small cutting amount and convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

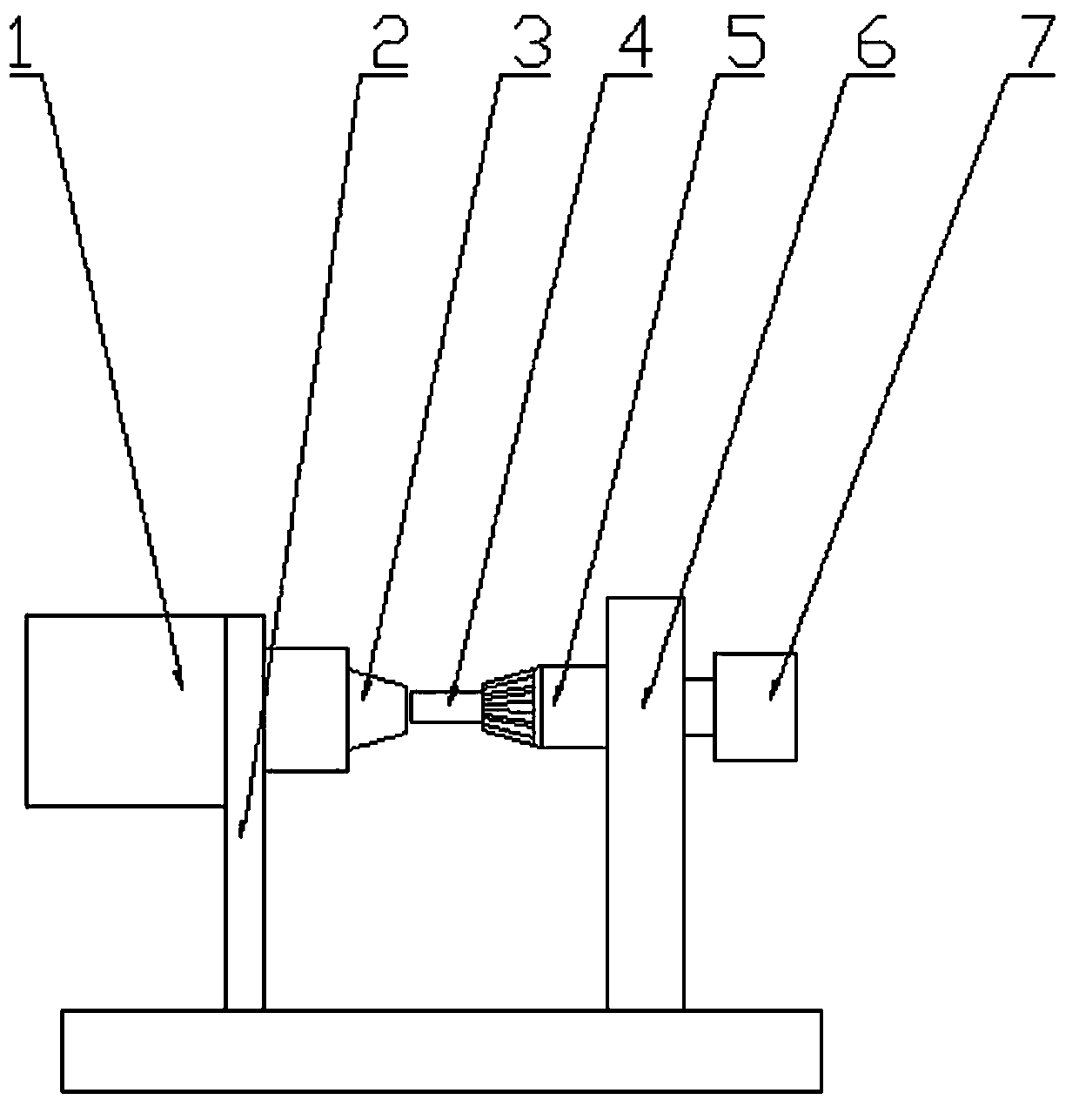

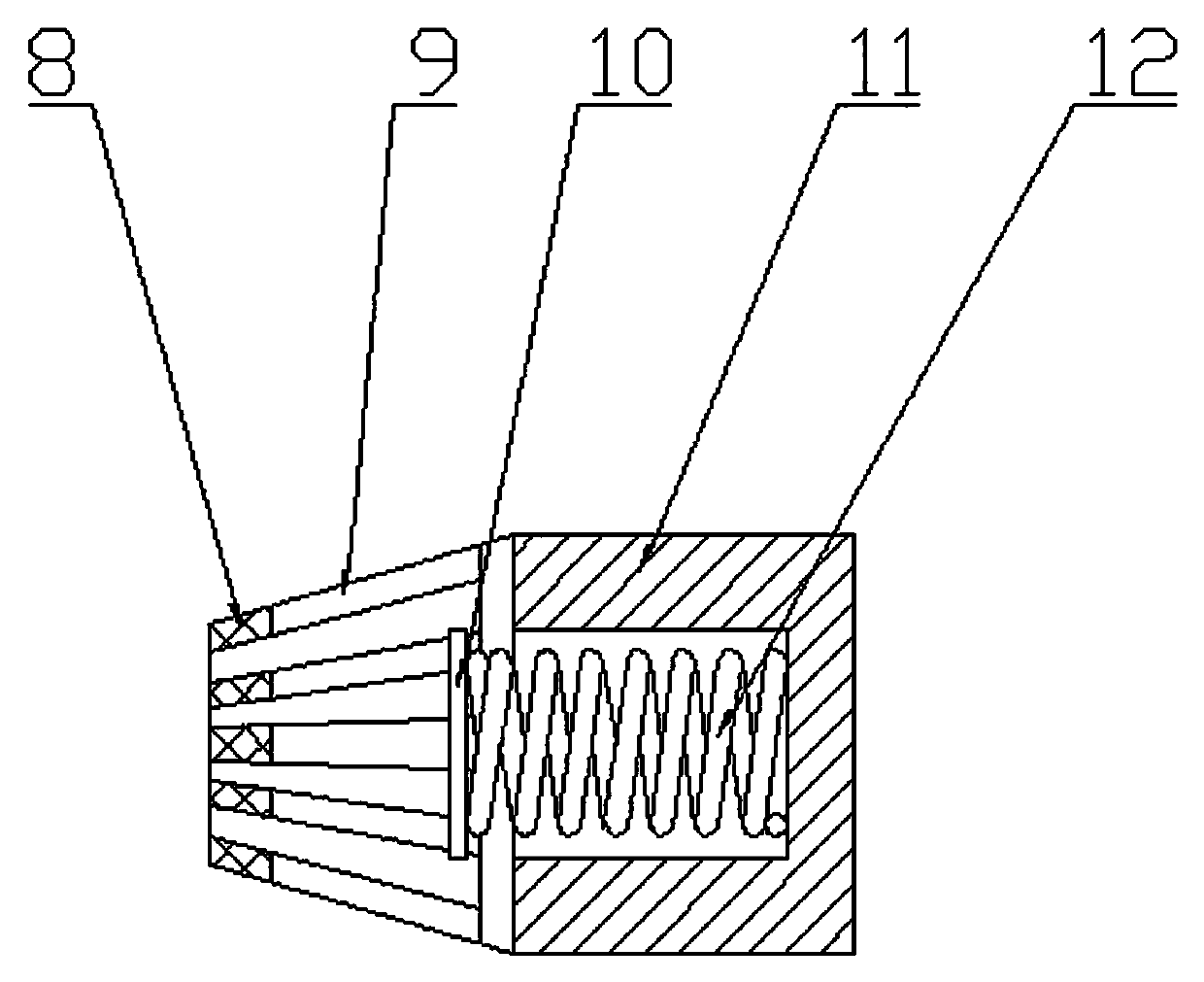

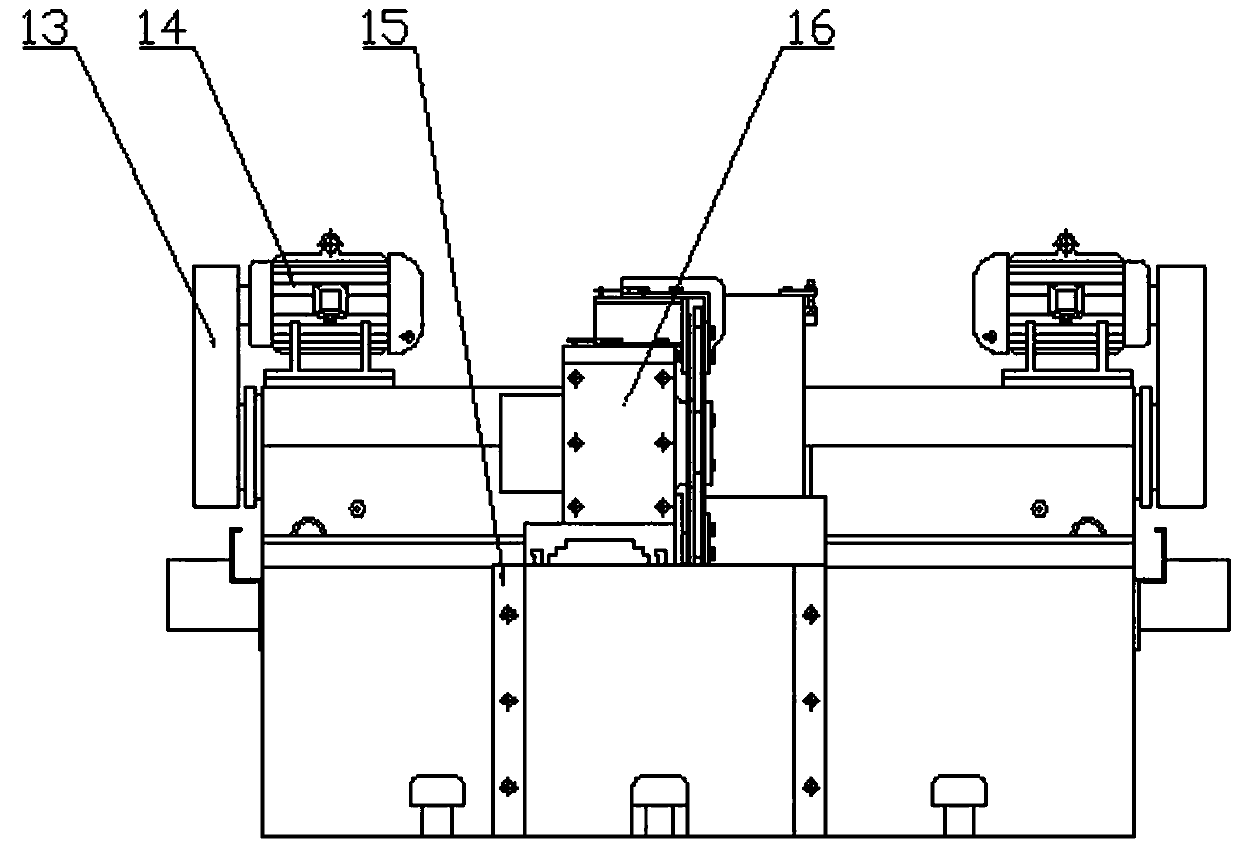

[0031] Example: such as Figure 1-6 Shown, a kind of casting alnico magnetic steel grinding process, according to the following steps:

[0032] Step 1: Mix and stir the raw materials of the magnetic steel 4 evenly, and then use an intermediate frequency furnace to melt and cast them. Among them, the components and mass percentages of the raw materials of the magnetic steel 4 are: 50% iron, 25% nickel, 12% Aluminum, 9% cobalt, 3% copper, 1% chromium.

[0033] Step 2: Insert the poured and cooled magnetic steel 4 into the cylindrical grinding jaw assembly 5 on the jaw mounting bracket 6, and then drive the motor 7 to drive the cylindrical grinding jaw assembly 5 to rotate. At this time, the telescopic cylinder The hydraulic telescopic cylinder 1 on the support 2 stretches and pushes the grinding cone 3 at the end, so that the grinding cone 3 pushes the magnetic steel 4 to feed the sliding grinder to process the outer circle in the outer grinding jaw assembly 5 .

[0034] When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com