Preparation method for block oligomeric dihydric alcohol with controllable structure

A technology of polyglycol and glycol, which is applied in the field of preparation of block-type oligomer glycol, can solve the problem of inability to synthesize segment block-type oligomer glycol and the like, and achieves a double metal cyanide catalyst. The effect of low concentration, low viscosity and moderate price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

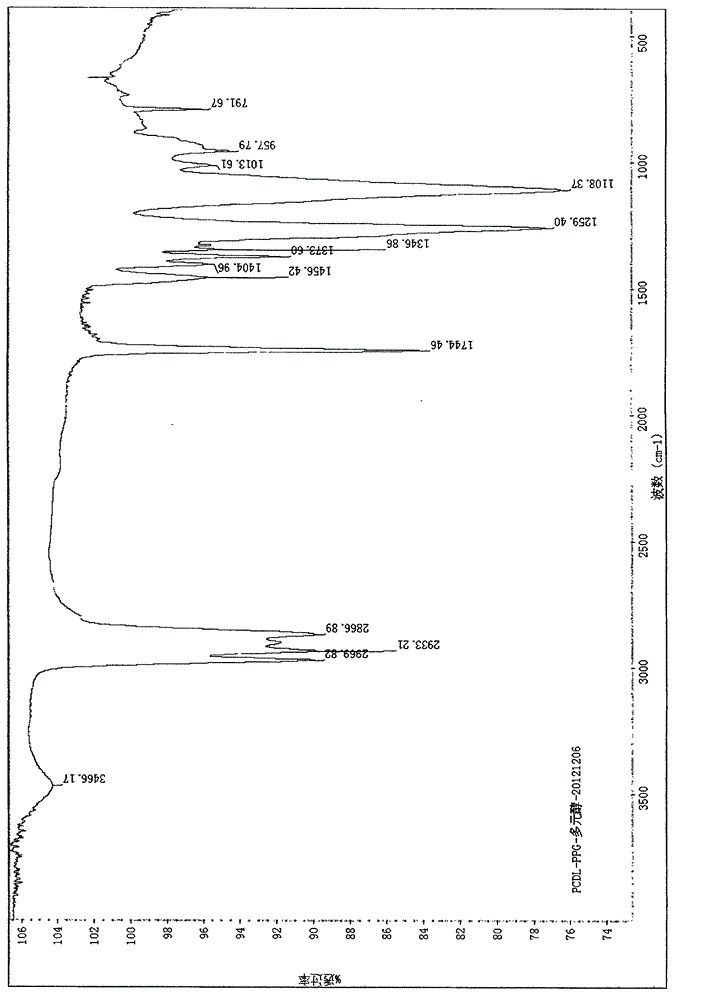

Image

Examples

preparation example Construction

[0040] The preparation method of polycarbonate diol is as follows:

[0041] Carbonic acid ester and dibasic alcohol are metered and thrown in the reaction kettle according to the ratio in the following table 1 according to a certain molar ratio, then add tetrabutyl titanate whose consumption is 0.25wt% of the dibasic alcohol feeding amount, pass into N 2 To exclude the air in the reaction system, heat the reaction system under normal pressure to gradually increase the temperature of the reaction system to 120° C., and react for 2 hours. Then gradually increase the temperature of the reaction system to 160°C, and react for 6 hours; finally, raise the temperature of the system to 180°C, then gradually reduce the absolute pressure of the system to 8kPa, keep the absolute pressure at 8KPa for 4h, and then cool to obtain a certain relative molecular mass. polycarbonate diol (PCDL).

[0042] Table 1 material ratio

[0043]

[0044] Polyester polyol:

[0045] 7. Polybutylene ad...

Embodiment 1

[0052] Embodiment 1: the preparation of a kind of block type oligomeric glycol, its preparation method is:

[0053] (1) Add 200g of polycarbonate diol PCDL-1 and 0.0123g of double metal cyanide complex catalyst DMC-B into a pressure-resistant stainless steel reactor with a volume of 1L, replace the air with nitrogen twice, start stirring, and heat to 110°C, remove moisture in vacuum for 1h.

[0054] (2) Then heat up to 120°C, first add 53g of propylene oxide to the reaction kettle in the above (1) for induction reaction, after the induction reaction is completed, gradually add the remaining 158g of propylene oxide dropwise, after the reaction is completed, remove Unreacted propylene oxide, to obtain block-type oligomeric diols, the yield is 99.2%, and the hydroxyl value measured by the phthalic anhydride-pyridine method (GB / T12008.3-2009) is 56.8mg KOH / g, and the average molecular weight is 1975.

[0055] The product structure formula is:

[0056]

Embodiment 2

[0062] Embodiment 2: the preparation of a kind of block type oligomeric glycol, its preparation method is:

[0063] (1) Add 200g of polycarbonate diol PCDL-2 and 0.628g of double metal cyanide complex catalyst DMC-A into a pressure-resistant stainless steel reactor with a volume of 1L, replace the air with nitrogen for 3 times, start stirring, and heat to 120°C, remove moisture under vacuum for 1h.

[0064] (2) Then heat up to 130°C, first add 128g propylene oxide to the reaction kettle in the above (1) for induction reaction, after the induction reaction is completed, gradually add the remaining 300g propylene oxide dropwise, after the reaction is completed, remove Unreacted propylene oxide, obtain block type oligomeric diol, yield is 98.8%, measure hydroxyl value by phthalic anhydride-pyridine method (GB / T12008.3-2009) 25.2mg KOH / g, average molecular weight is 4452.

[0065] The product structure formula is:

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com