Manufacturing process of sprue bushing provided with special water channel device

A production process and water channel technology, applied in the direction of manufacturing tools, welding equipment, heat treatment equipment, etc., can solve the problem of no temperature adjusting device, etc., and achieve the effect of simple production process and reasonable water channel layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

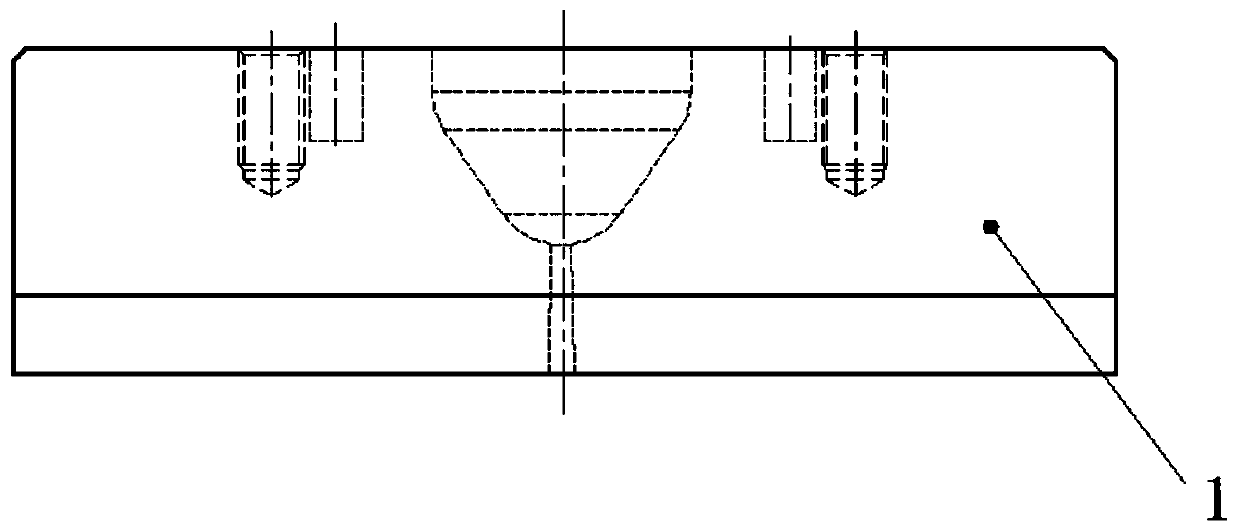

[0033] The manufacturing process of the nozzle provided with the special water channel device of the present invention is applicable to various cavity molds.

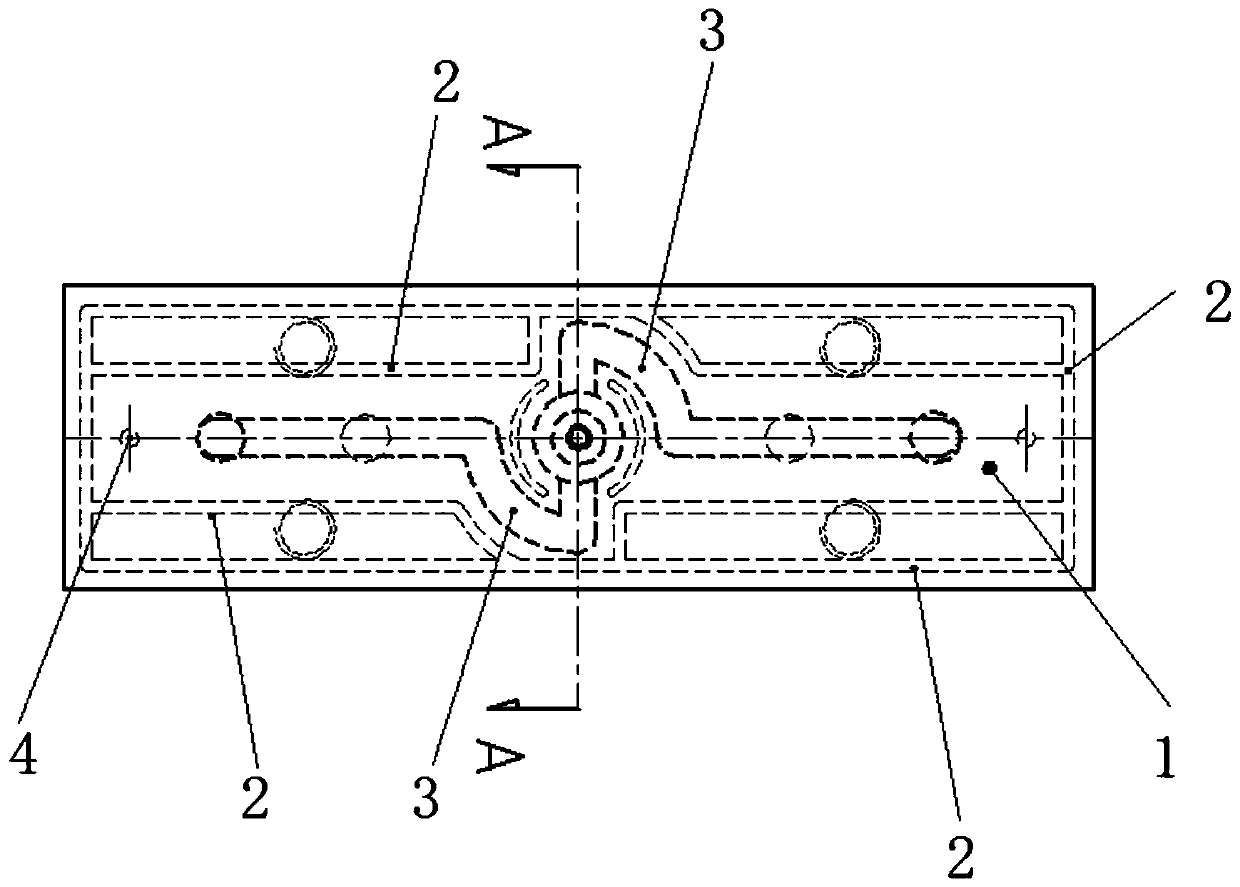

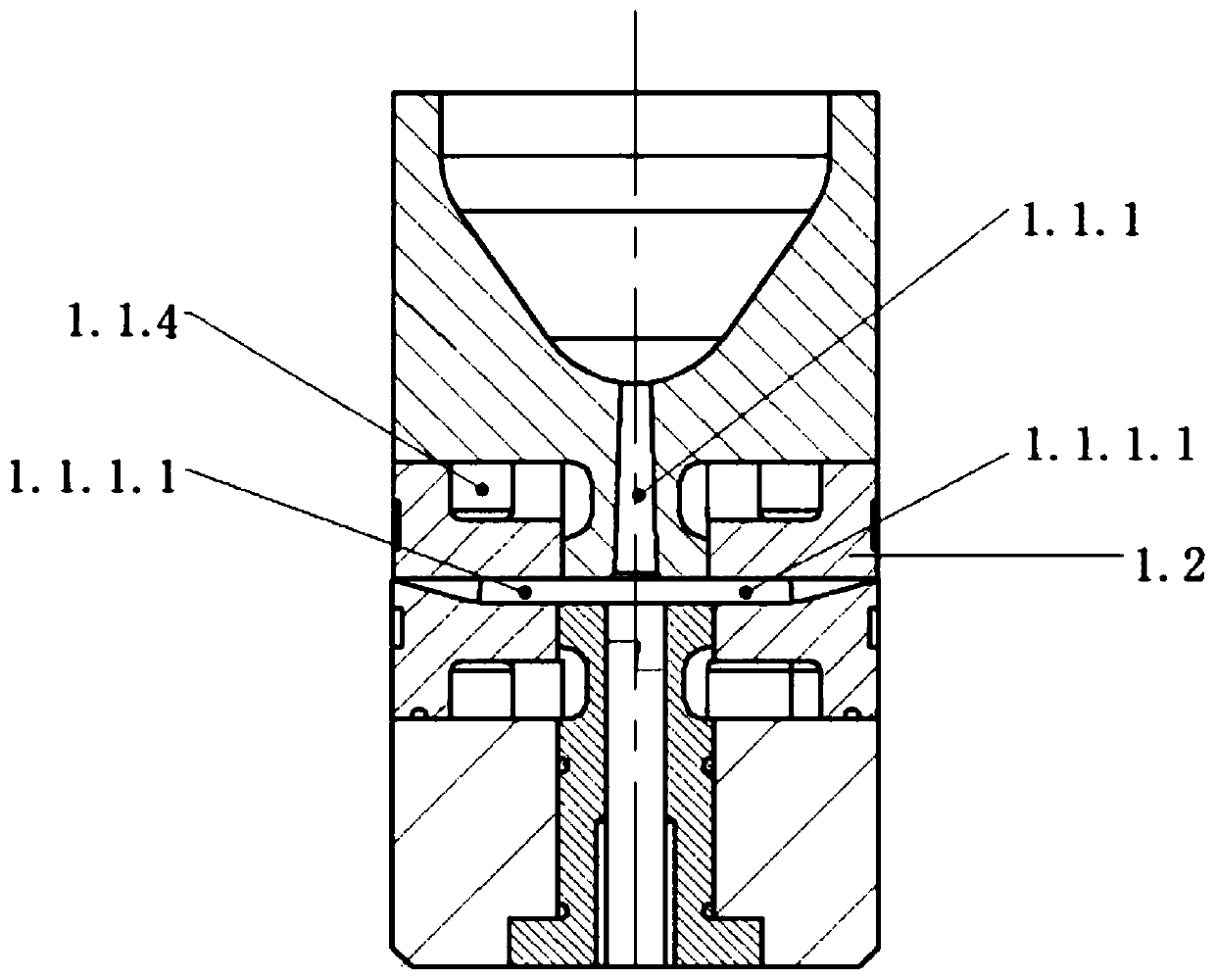

[0034] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 , to describe in detail the preferred embodiment and other embodiments of the manufacturing process of the nozzle provided with the special waterway device of the present invention.

[0035] The present invention provides a manufacturing process of a nozzle provided with a special waterway device, which is characterized in that it includes the following steps:

[0036] (1) Make the nozzle seat module 1.1 and the water channel module 1.2 respectively.

[0037] (2) Coating brazing filler metal on the nozzle seat module 1.1 and between the water channel module 1.2.

[0038] (3) Clamp the nozzle seat module 1.1 and the water channel module 1.2.

[0039] (4) In a hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com