A method for on-line state monitoring of igbt module bonding wires

A technology for bonding wires and power modules, which is applied in the fields of power electronics and electronic information science, and can solve the problems of IGBTs that do not consider changes in working conditions, low accuracy, and no description of the measurement of the collector-emitter voltage drop of IGBT modules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

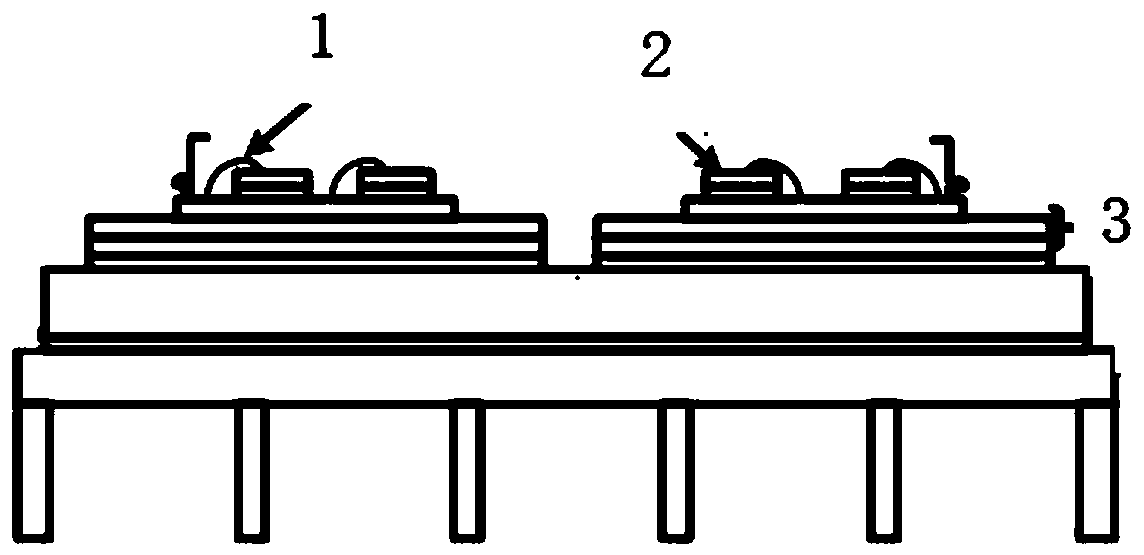

[0054] In this embodiment, the SKM50GB12T4 power module of the SEMKRON series is used for experimental verification, and six bonding wires are used to connect the chip and the substrate in parallel.

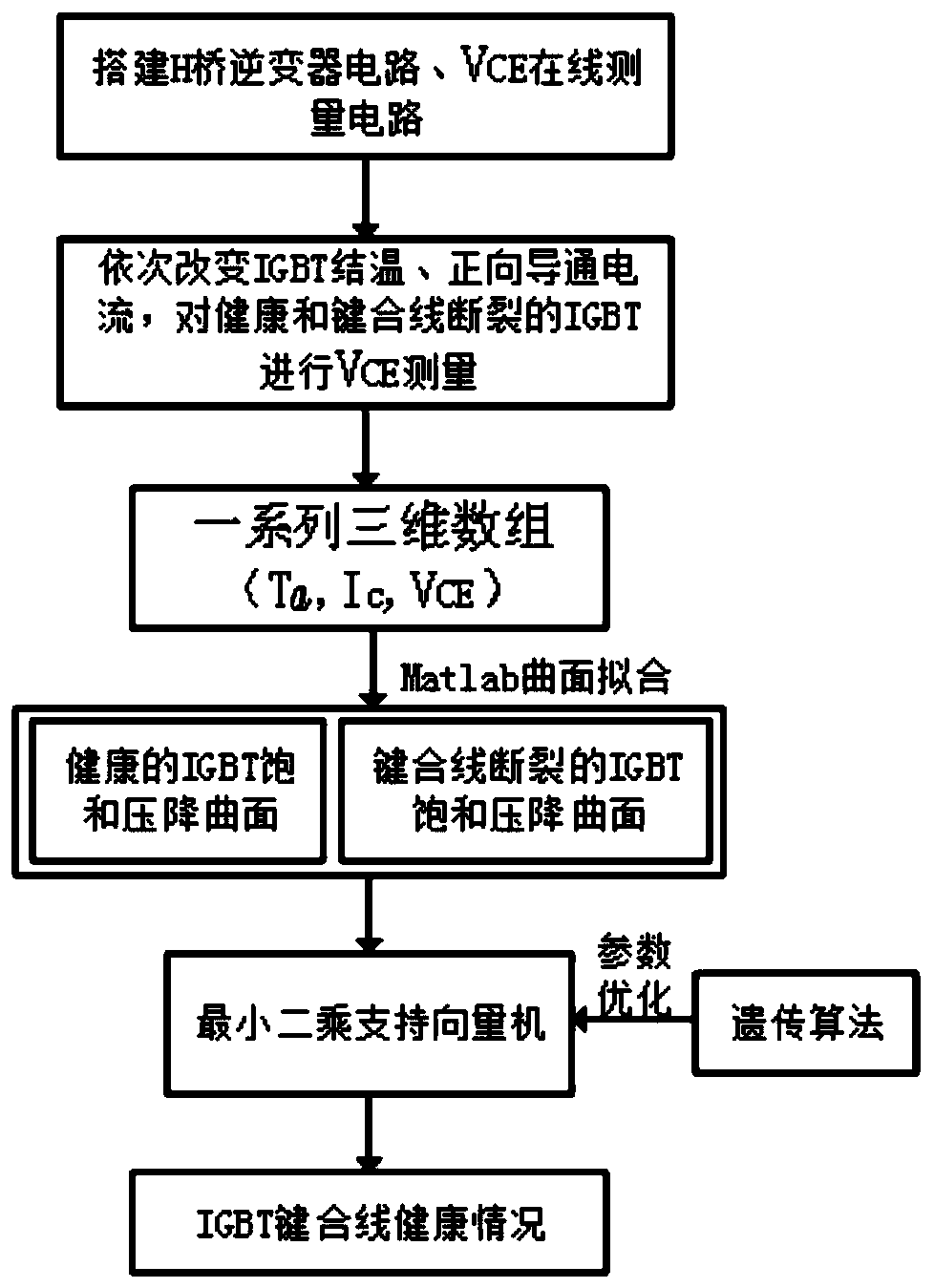

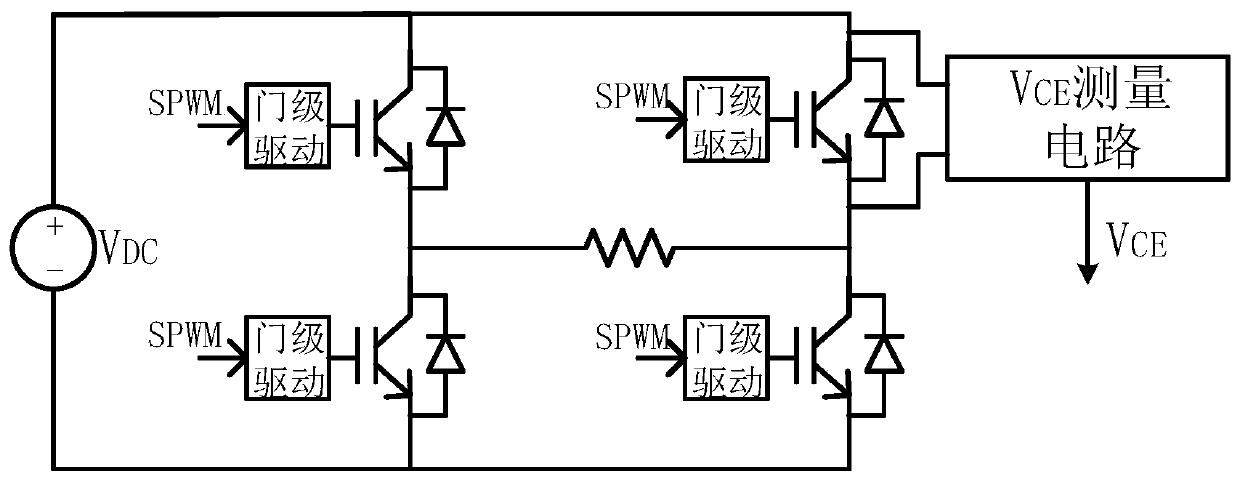

[0055] like figure 1 As shown, the present invention provides a method for online state monitoring of IGBT module bonding wires, as follows image 3 The shown full-bridge inverter circuit is taken as an example to introduce the implementation process of this method in detail. The specific implementation steps are as follows:

[0056] Step 1. Build the full-bridge inverter circuit and V CE In-line measurement circuit, the V CE The two input terminals of the online measurement circuit are connected to the collector and emitter of the IGBT power module of the full-bridge inverter circuit to realize the connection between the full-bridge inverter circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com