Cyclohexyl LED packaging material and preparation method thereof

A technology of LED packaging and cyclohexyl, which is applied in the fields of electronic chemicals and polymer science, can solve the problems of high-temperature yellowing of phenyl, high-temperature yellowing, and ultraviolet aging yellowing, etc., and achieve high light transmittance and high refraction High index and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

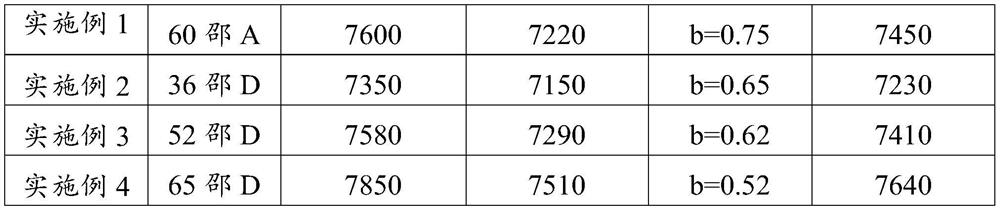

Embodiment 1

[0047] As an embodiment of the cyclohexyl LED packaging material of the present invention, the cyclohexyl LED packaging material described in this embodiment includes the following components by weight:

[0048] 100 g of cyclohexyl vinyl silicone resin, 100 g of cyclohexyl hydrogen silicone resin, 0.02 g of inhibitor (methyl ethynyl alcohol), 0.08 g of platinum catalyst (5000 ppm) coordinated by methyl vinyl siloxane, and adhesive (ene Propyl glycidyl ether) 4g.

[0049] The preparation method of the cyclohexyl LED encapsulation material of the present embodiment comprises the following steps:

[0050] (1) preparation of cyclohexyl vinyl elastomeric polymer:

[0051] (1a) Add 15 grams of methylvinyldimethoxysilane, 150 grams of dicyclohexyldimethoxysilane, 150 grams of methylcyclohexyldimethoxysilane, and cyclohexyltriethoxysilane into a 3000ml four-necked flask. 120 grams of base silane, 800 grams of xylene and 1 gram of zinc benzoate, stirred evenly;

[0052] (2a) Add 800...

Embodiment 2

[0062] As an embodiment of the cyclohexyl LED packaging material of the present invention, the cyclohexyl LED packaging material described in this embodiment includes the following components by weight:

[0063] Cyclohexyl vinyl silicone resin 100g, cyclohexyl hydrogen-containing silicone resin 200g, inhibitor (methyl ethynyl alcohol) 0.06g, methyl vinyl siloxane coordinated platinum catalyst (3000ppm) 0.3g, adhesive (ene Propyl glycidyl ether) 5g.

[0064] The preparation method of the cyclohexyl LED encapsulation material of the present embodiment comprises the following steps:

[0065] (1) Preparation of cyclohexyl vinyl silicone resin:

[0066] (1a) Add 60 g of trimethyl-ethoxysilane, 300 g of cyclohexyltriethoxysilane, 50 g of methylcyclohexyldimethoxysilane, 100 g of dicyclohexyldimethoxysilane, 100g tetraethyl orthosilicate, 100g butanol, 1000g xylene and 1.2g aluminum triisopropoxide, stir well;

[0067] (1b) Add 1000g of distilled water dropwise when the temperatur...

Embodiment 3

[0079] As an embodiment of the cyclohexyl LED packaging material of the present invention, the cyclohexyl LED packaging material described in this embodiment includes the following components by weight:

[0080] 50 g of cyclohexyl vinyl silicone resin, 200 g of cyclohexyl hydrogen-containing silicone resin, 0.025 g of inhibitor (methyl ethynyl alcohol), 0.25 g of platinum catalyst (3000 ppm) coordinated by methyl vinyl siloxane, adhesive (ene Propyl glycidyl ether) 5g.

[0081] The preparation method of the cyclohexyl LED packaging material of the present embodiment comprises the following steps:

[0082] (1) Preparation of cyclohexyl vinyl silicone resin:

[0083] (1a) Add 50 grams of trimethyl-ethoxysilane, 15 grams of vinyldimethylethoxysilane, 250 grams of cyclohexyltriethoxysilane, and vinyltriethoxysilane into a 5000ml four-necked flask. 15 grams, 20 grams of methylvinyldimethoxysilane, 84 grams of methylcyclohexyldimethoxysilane, 150 grams of dicyclohexyldimethoxysila...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| optical indicatrix | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com