High-flow heat-conducting nylon composite material, preparation method and application thereof

A nylon composite material and high-flow technology, applied in the field of composite materials, can solve the problems of poor fluidity of nylon products, low fluidity of nylon materials, and application limitations, and achieve the effect of improving fluidity, significant technology and market value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0025] In the present invention, the type of the antioxidant is not particularly limited, and it may be various existing auxiliary agents capable of improving the oxidation resistance of the nylon composite material. According to a preferred embodiment of the present invention, the antioxidant is a composite antioxidant containing a primary antioxidant and an auxiliary antioxidant, wherein the primary antioxidant is a hindered phenolic antioxidant (such as 1010), the auxiliary antioxidant is selected from at least one of phosphite antioxidants, mercaptan antioxidants and thioester antioxidants. In addition, the weight ratio of the primary antioxidant to the secondary antioxidant is preferably 1:(1-3).

[0026] The present invention is not particularly limited to the type of the lubricant, and can be various existing auxiliary agents that can improve the lubricating performance of nylon composite materials, and its specific examples include but are not limited to: pentaerythrit...

Embodiment 1

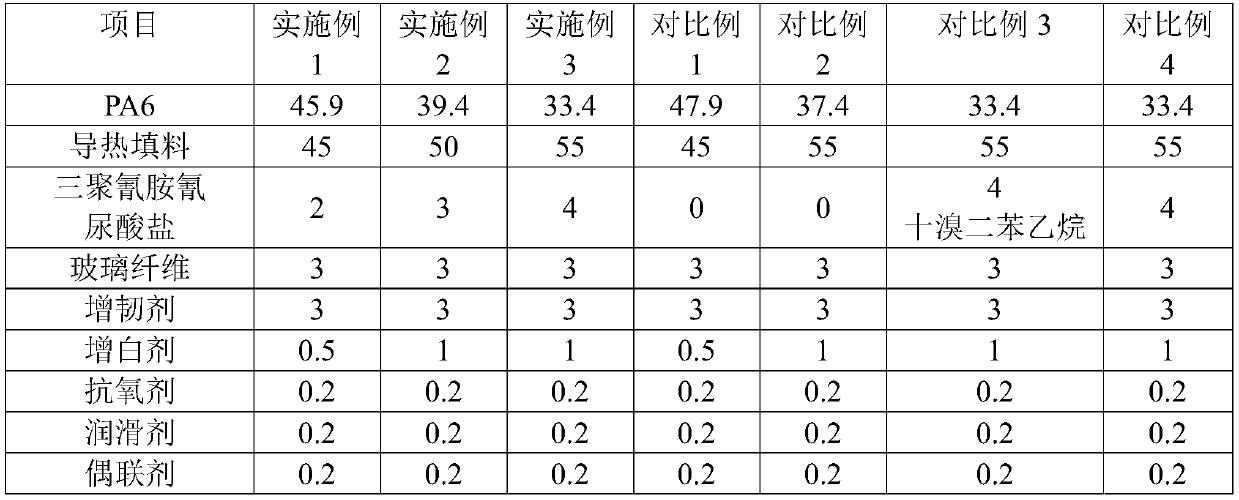

[0032]Weigh various raw materials according to the material ratio in Table 1, and mix nylon resin (PA6, relative viscosity of 2), thermally conductive filler (magnesium hydroxide), melamine cyanurate, glass fiber (monofilament diameter 10-13 μ m and length 3 ~5mm chopped glass fiber), toughening agent (polyethylene grafted maleic anhydride (PE-MAH), polyethylene graft rate 0.4wt%), whitening agent (rutile titanium dioxide), antioxidant (Compound of 1010 and 168 according to the weight ratio of 1:2), lubricant (ethylene bis stearic acid amide) and coupling agent (KH-550) were added to the high-speed mixing pot and mixed for 3 minutes to obtain a premix. Afterwards, the premixed material is fed into a twin-screw extruder from the main feeding port, and subjected to melt extrusion, cooling, and granulation to obtain a high-fluidity heat-conducting nylon composite material. Wherein, the extrusion temperature of the twin-screw extruder is set at 200-260° C., and the rotation speed ...

Embodiment 2

[0034] Weigh various raw materials according to the ratio of materials in Table 1, nylon resin (PA6, relative viscosity is 2.4), thermal conductive filler (aluminum hydroxide), melamine cyanurate, glass fiber (monofilament diameter 10 ~ 13μm and length 3 ~5mm chopped glass fiber), toughening agent (polyethylene grafted maleic anhydride (PE-MAH), polyethylene graft rate 1.0wt%), whitening agent (rutile titanium dioxide), antioxidant (Compound of 1010 and 168 according to the weight ratio of 1:2), lubricant (butyl stearate) and coupling agent (KH-560) were added into a high-speed mixing pot and mixed for 3 minutes to obtain a premix. Afterwards, the premixed material is fed into a twin-screw extruder from the main feeding port, and subjected to melt extrusion, cooling, and granulation to obtain a high-fluidity heat-conducting nylon composite material. Wherein, the extrusion temperature of the twin-screw extruder is set at 200-260° C., and the rotation speed is set at 250 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Grafting rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com