Special material for preset breakage point loop filter element

A technology of breaking point and terry, which is applied in the field of special polypropylene formula, can solve the problems of short replacement cycle of filter elements, poor filter water quality, increased pressure of filter elements, etc., and achieve extended replacement cycle, high elastic modulus of velvet fiber, and high pile rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Included by weight percentage:

[0027] Isotactic polypropylene 91%;

[0029] Benzoyl Peroxide 1.5%;

[0030] Polybutene 2%;

[0031] Titanate coupling agent 1%

[0032] Antioxidant 2%

[0033] Polyhexamethylene adipamide 1%

[0034] The antioxidant is composed of antioxidant 168 and antioxidant 1010 in a weight ratio of 1:0.4-1.

[0035] The preparation method comprises the following steps:

[0036] 1. Add the raw materials into the high-speed mixer in proportion, and stir at a speed of 200 rpm for 10 rpm.

[0037] 2. Pour the blended material into a granulator to melt and extrude to make 10mm diameter granules, and the granulation temperature is 240 degrees.

[0038] 3. Hot air drying with moisture content below 50PPM.

Embodiment 2

[0040] Included by weight percentage:

[0041] Isotactic polypropylene 92%;

[0043] Benzoyl Peroxide 1.2%;

[0044] Polybutene 1.8%;

[0045] Titanate coupling agent 0.7%

[0046] Antioxidant 1.3%

[0047] Polyhexamethylene adipamide 1%

[0048] The antioxidant is composed of antioxidant 168 and antioxidant 1010 in a weight ratio of 1:0.4-0.8.

[0049] The preparation method comprises the following steps:

[0050] 1. Add the raw materials into the high-speed mixer in proportion, and stir at a speed of 200 rpm for 10 rpm.

[0051] 2. Pour the blended material into a granulator to melt and extrude to make 15mm diameter granules, and the granulation temperature is 250 degrees.

[0052] 3. Hot air drying with moisture content below 50PPM

Embodiment 3

[0054] Included by weight percentage:

[0055] Isotactic polypropylene 90%;

[0057] Benzoyl Peroxide 1%;

[0058] Polybutene 3%;

[0059] Titanate coupling agent 1%

[0060] Antioxidant 1.4%

[0061] Polyhexamethylene adipamide 0.6%

[0062] The antioxidant is composed of antioxidant 168 and antioxidant 1010 in a weight ratio of 1:0.4.

[0063] The preparation method comprises the following steps:

[0064] 1. Add the raw materials into the high-speed mixer in proportion, and stir at a speed of 200 rpm for 10 rpm.

[0065] 2. Pour the blended material into a granulator to melt and extrude to make 20mm diameter granules, and the granulation temperature is 280 degrees.

[0066] 3. Hot air drying with moisture content below 50PPM.

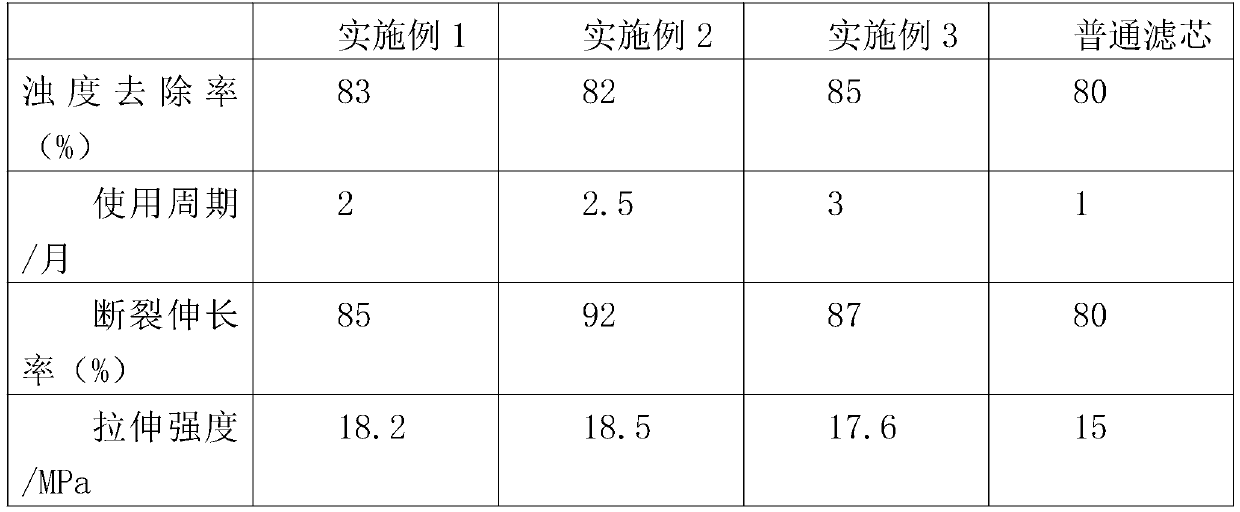

[0067] The performance test data is as follows:

[0068]

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com