Direct current oil-free brushless decompression pantograph rise pump

A pressure relief and pressure relief valve technology, applied in the field of DC oil-free and brushless bow lift pumps, can solve the problems of high protection level and large starting torque, and achieve low protection level, large starting torque and strong overload capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

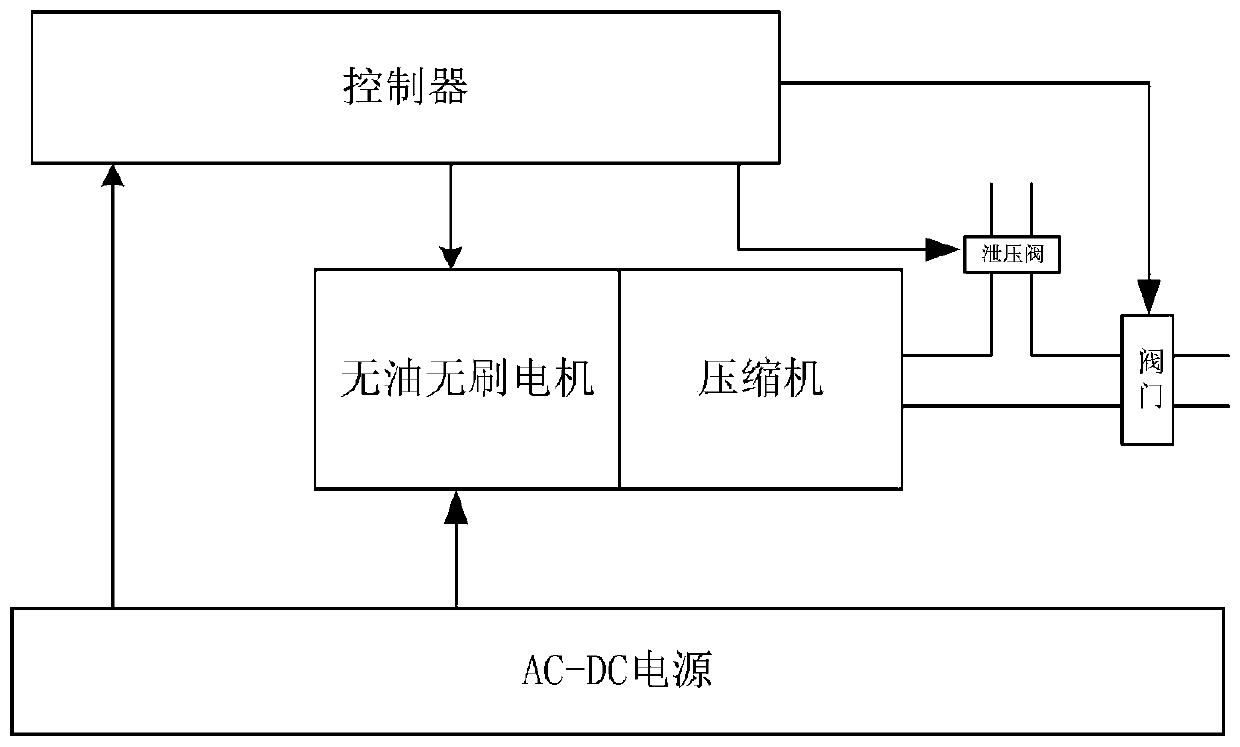

[0016] see figure 1 , a DC oil-free, brushless, pressure-relief lifting bow pump, the lifting bow pump is composed of an oil-free brushless motor, a controller, a compressor, a valve, a pressure relief valve and a DC-DC power supply; the oil-free The brush motor adopts DC power supply, and the output shaft of the motor is connected to the compressor; the output end of the compressor is connected to the output pipeline, and the end of the output pipeline is connected to the valve, and the valve and the compressor are directly connected to the pressure relief valve through a three-way valve; the DC- The DC power supply is used to convert 220V AC to DC; when in use, the oil-free brushless motor, valve and pressure relief valve are under the control of the controller. When external pressure is required, the controller controls the operation of the oil-free brushless motor to drive When the compressor is running, the valve opens and the pressure relief valve closes. When the requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com