Epoxy-structure adhesive for prefabrication and splicing of bridge segment

An adhesive and epoxy technology, applied in the direction of adhesives, novolac epoxy resin adhesives, epoxy resin adhesives, etc., to achieve the effects of fast strength growth, long service life, and long operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

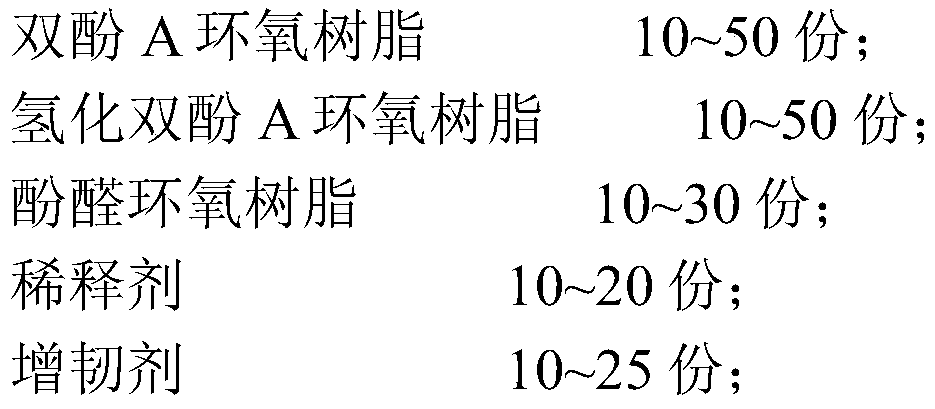

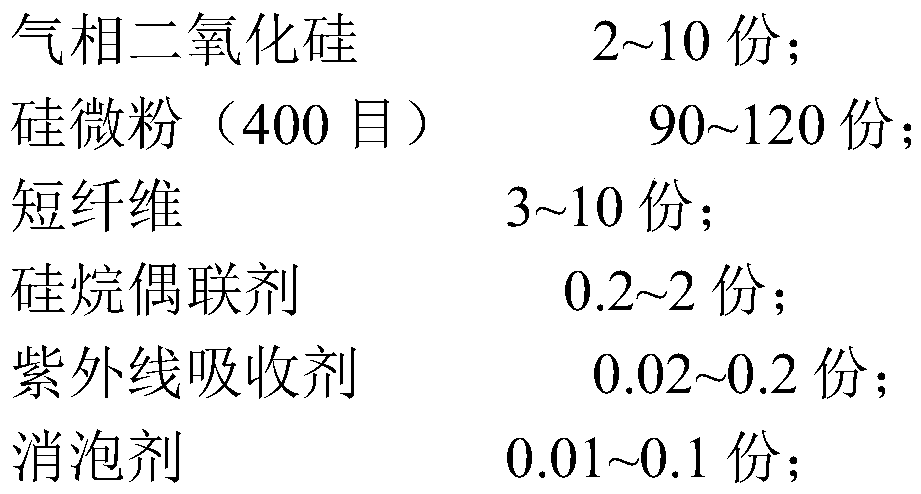

[0056] A component

[0057] Bisphenol A epoxy resin: 30 parts, hydrogenated bisphenol A epoxy resin: 25 parts, novolac epoxy resin: 15 parts, thinner: 16 parts, toughening agent: 10 parts, fumed silica: 7 parts, Silica powder (400 mesh): 95 parts, short fiber: 4 parts, silane coupling agent: 1 part, ultraviolet absorber: 0.12 parts, defoamer: 0.06 parts.

[0058] B component

[0059] Phenolic modified polyamidoamine: 20 parts, self-catalyzed modified alicyclic amine: 20 parts, cardanol aminal: 24 parts, highly active silane coupling agent: 4 parts.

[0060] The highly active silane coupling agent is ND-42 (anilinomethyltriethoxysilane).

[0061] A component: B component = 3:1 (weight ratio), the use temperature is 5°C~20°C.

Embodiment 2

[0063] A component

[0064] Bisphenol A epoxy resin: 35 parts, hydrogenated bisphenol A epoxy resin: 20 parts, novolac epoxy resin: 15 parts, thinner: 10 parts, toughening agent: 15 parts, fumed silica: 7 parts, Silica powder (400 mesh): 100 parts, short fiber: 5 parts, silane coupling agent: 1 part, ultraviolet absorber: 0.12 parts, defoamer: 0.06 parts.

[0065] B component

[0066] Phenolic modified polyamide-amine: 20 parts, self-catalyzed modified alicyclic amine: 12 parts, cardanol aminal: 32 parts, highly active silane coupling agent: 4 parts.

[0067] The highly active silane coupling agent is Y-9669 (N-phenyl-Y-aminopropyltrimethoxysilane).

[0068] A component: B component = 3:1 (weight ratio), and the use temperature is 15°C to 30°C.

Embodiment 3

[0070] A component

[0071] Bisphenol A epoxy resin: 40 parts, hydrogenated bisphenol A epoxy resin: 15 parts, novolac epoxy resin: 15 parts, thinner: 10 parts, toughening agent: 15 parts, fumed silica: 6 parts, Silica powder (400 mesh): 106 parts, short fiber: 5 parts, silane coupling agent: 1

[0072] parts, UV absorber: 0.12 parts, defoamer: 0.06 parts.

[0073] B component

[0074] Phenolic modified polyamide-amine: 28 parts, self-catalyzed modified alicyclic amine: 4 parts, cardanol aminal: 32 parts, highly active silane coupling agent: 4 parts.

[0075] The highly active silane coupling agent is Y-9669 (N-phenyl-Y-aminopropyltrimethoxysilane).

[0076] A component: B component = 3:1 (weight ratio), the use temperature is 25°C ~ 40°C.

[0077] Performance tests were performed on the above three formula samples, including operating time, compressive strength, and damp heat aging resistance. The working time refers to the time when the viscosity of the adhesive increas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com