Silicolite heat insulation board and preparation technology thereof

A technology of thermal insulation board and rock quality, which is applied to the field of siliceous rock thermal insulation board and its preparation technology, and can solve the problems of easy cracking, poor bonding of thermal insulation board, poor thermal insulation and flame retardant effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

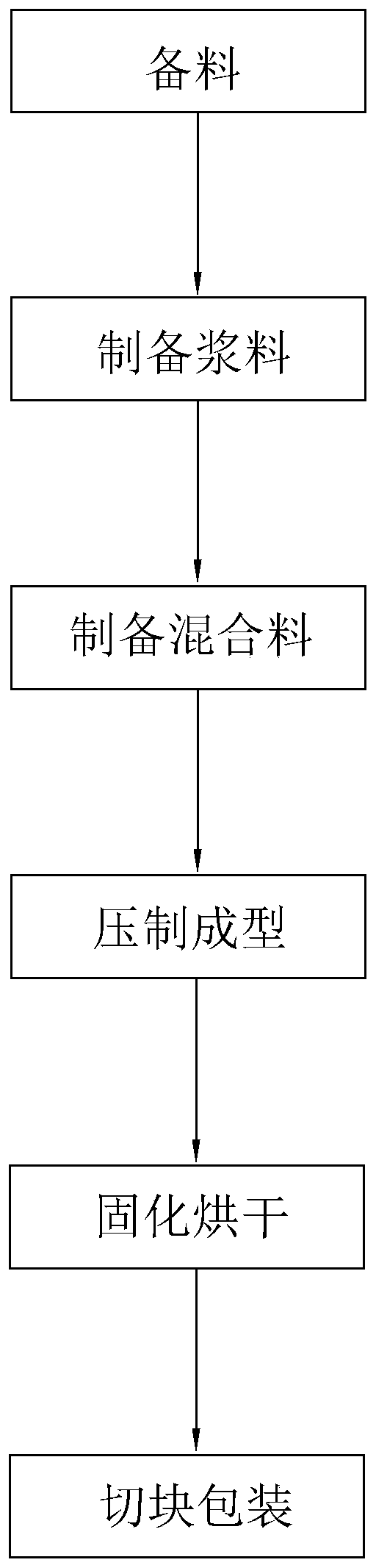

Method used

Image

Examples

Embodiment 1

[0058] Example 1: A siliceous thermal insulation board, the components and their corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0059] Step 1, prepare materials, take the following components by weight: metakaolin 120kg, silica sol 20kg, silicate ceramic particles 20kg, waste rubber powder 4kg, wood fiber 0.6kg, isooctyltriethoxysilane 0.2kg, and Mix evenly to obtain powder;

[0060] Step 2, prepare the slurry, add water with 55% of the total weight of the powder, and stir to obtain a uniform particle-free slurry;

[0061] Step 3, preparing a mixture, adding 9kg of EPS particles into the slurry, and fully stirring to obtain a mixture;

[0062] Step 4, compression molding, the mixture obtained in step 3 is compressed and molded through a compression mold, and the compression ratio is 35%;

[0063] Step 5, curing and drying, put the module obtained in step 4 together with the mold into a 45°C drying room, remove the mold aft...

Embodiment 2-8

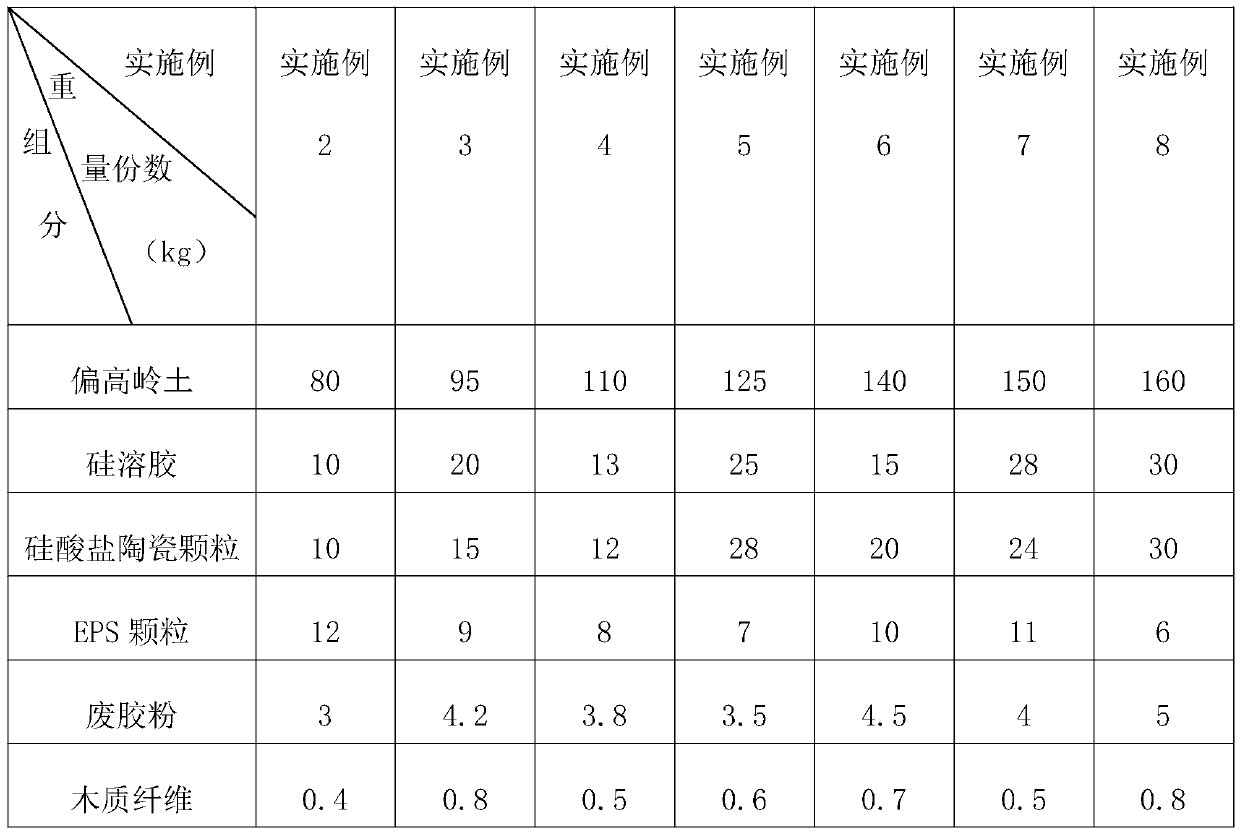

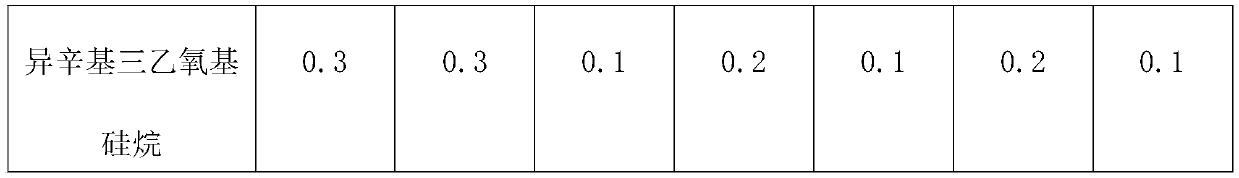

[0066] Embodiment 2-8: A siliceous thermal insulation board. The difference from Embodiment 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0067] Each component and parts by weight thereof in table 1 embodiment 1-8

[0068]

[0069]

Embodiment 9

[0070] Embodiment 9: A siliceous thermal insulation board. The difference from Embodiment 1 is that step 1 is specifically set as, preparing materials, and weighing the following components by weight: metakaolin 120kg, aluminate cement 20kg, porous filler 20kg, waste rubber powder 4kg, wood fiber 0.6kg, isooctyltriethoxysilane 0.2kg, and mix uniformly to obtain powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com