All-steel radial tire with 90-degree belt structure

A technology of radial tires and belt layers, which is applied to tire parts, reinforcement layers of pneumatic tires, vehicle components, etc., can solve problems such as non-abrasion resistance and partial wear, insufficient steering ability, and easy groove cracks, etc., and achieve reduction Effects of lateral deformation, suppression of lateral expansion, increase of lateral rigidity and righting moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1, the all-steel radial tire is made of rubber steel wire reinforcement material, due to the viscoelasticity of the rubber material, it exhibits technical characteristics such as large deformation nonlinearity, temperature sensitivity and easy thermo-oxidative aging. All-steel radial tires can be roughly divided into three parts: tread, sidewall and bead.

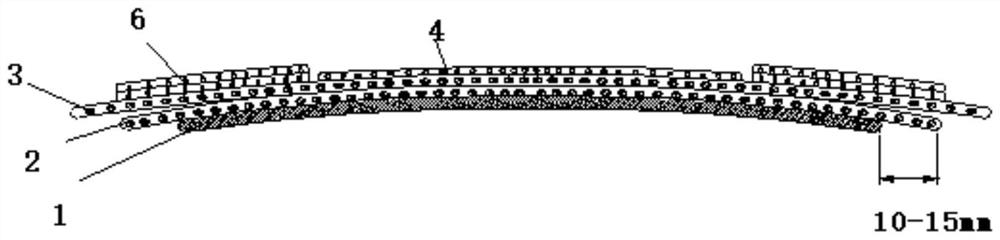

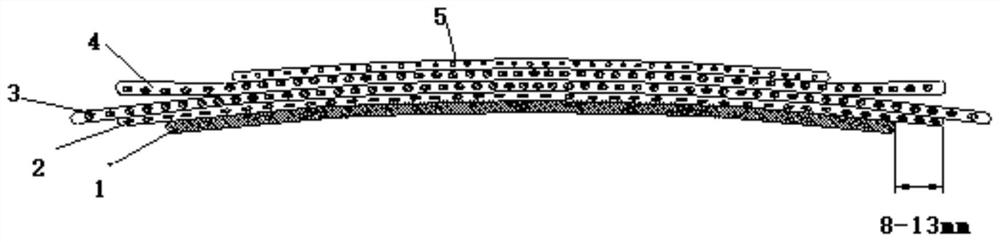

[0034] This application is mainly aimed at improving the design of the belt layer of the tread and the geometrical features of the contour. At present, there are mainly two types of belt layers that are more common in China, namely, a four-layer belt stack structure, and a 0-degree belt layer + three-layer belt layer stack structure.

[0035] This application is based on the existing technology. The 1# belt layer adopts a 90° carcass steel wire structure and supplemented by a comprehensive optimization configuration of the belt layer range and shoulder thickness, so as to increase the lateral rigidity and ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com