Silicon-carbon composite material and preparation method thereof, and application of silicon-carbon composite material

A technology of silicon-carbon composite materials and silicon-based materials, applied in nanotechnology, electrical components, electrochemical generators, etc. for materials and surface science, can solve problems such as poor reversible specific capacity, reduce consumption and increase reversibility Effect of specific capacity and high reversible specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

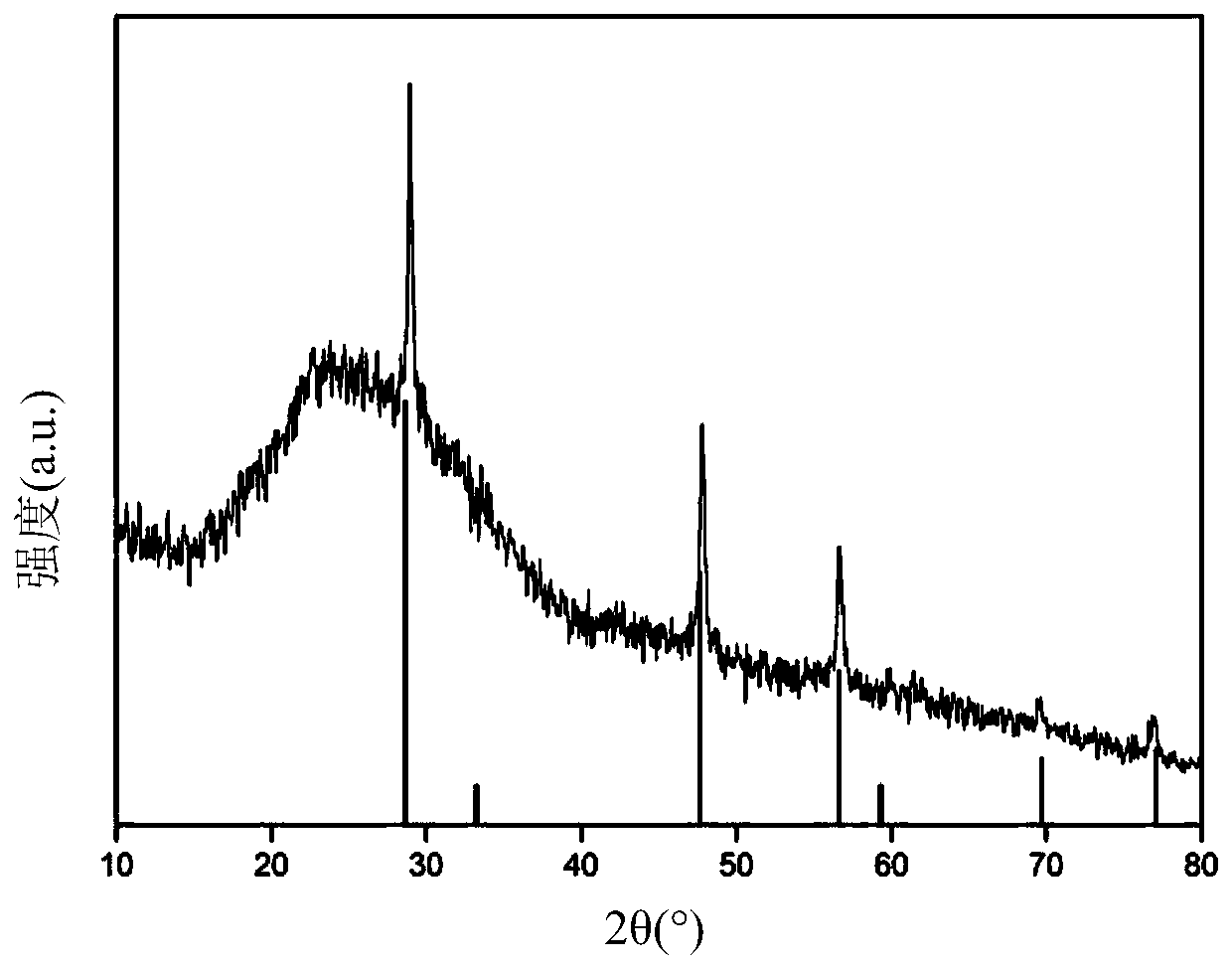

[0041] (1) Add 0.1625g metal magnesium powder, 0.1993g diatomite powder and 2.2025g sodium chloride powder into the ball mill and ball mill at a speed of 180r / min for 2.5h, then put the resulting mixture into a tube furnace, and feed Argon gas was used as a protective atmosphere, and the temperature was raised to 650°C at a rate of 2°C / min for 3 hours, and then cooled to room temperature naturally, and the product was placed in 65ml of 1mol / L hydrochloric acid solution and washed for 5.5h, then centrifuged, and circulated according to this method Wash and centrifuge 3 times, and finally put the product into a vacuum oven to dry for 12 hours to obtain a silicon-based material.

[0042] (2) Get 120 mg of the silicon-based material obtained in step (1) and disperse it into a mixed solution consisting of 320 ml of absolute ethanol and 80 ml of deionized water, perform ultrasonic treatment, then add 4 ml of concentrated ammonia water (mass fraction: 28%, the same below), then under...

Embodiment 2

[0047] (1) Put 0.2400g metal magnesium powder, 0.3041g diatomite powder and 3.0451g sodium chloride powder into the ball mill and ball mill at a speed of 120r / min for 10h, then put the resulting mixture into a tube furnace and pass through argon Gas was used as a protective atmosphere, and the temperature was raised to 700°C at a rate of 5°C / min for 3 hours, and then cooled to room temperature naturally, and the product was placed in 65ml of 1mol / L hydrochloric acid solution for stirring and washing for 6 hours, then centrifuged, and the centrifuged cycle was washed according to this method 3 times, and finally put the product into a vacuum drying oven to dry for 12 hours to obtain a silicon-based material.

[0048] (2) Take 150 mg of the silicon-based material obtained in step (1) and disperse it into a mixed solution composed of 320 ml of absolute ethanol and 80 ml of deionized water, and perform ultrasonic treatment, then add 4 ml of concentrated ammonia water to the resulti...

Embodiment 3

[0053] (1) Add 0.3120g metal magnesium powder, 0.4010g diatomite powder and 4.1430g sodium chloride powder into the ball mill and ball mill at a speed of 150r / min for 6h, then put the resulting mixture into a tube furnace and pass through argon Air was used as a protective atmosphere, and the temperature was raised to 650°C at a rate of 5°C / min for 6 hours, and then cooled to room temperature naturally, and the product was placed in 65ml of 3mol / L hydrochloric acid solution for stirring and washing for 8 hours, and then centrifuged. 3 times, and finally put the product into a vacuum drying oven to dry for 12 hours to obtain a silicon-based material.

[0054] (2) Disperse 150 mg of the silicon-based material obtained in step (1) into a mixed solution consisting of 200 ml of absolute ethanol and 50 ml of deionized water, perform ultrasonic treatment, then add 2.5 ml of concentrated ammonia water to the resulting dispersion, and then Under vigorous stirring, 1 ml of ethyl orthosi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Inverse capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com