Method for improving quality of inner surface of 3D printed part

A 3D printing, inner surface technology, applied in the field of 3D printing, can solve the problems of not mentioning the degradation effect of the etching process, difficult to control the accuracy of the internal structure, etc., to improve the anti-oxidation ability, easy to control and operate, and good effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

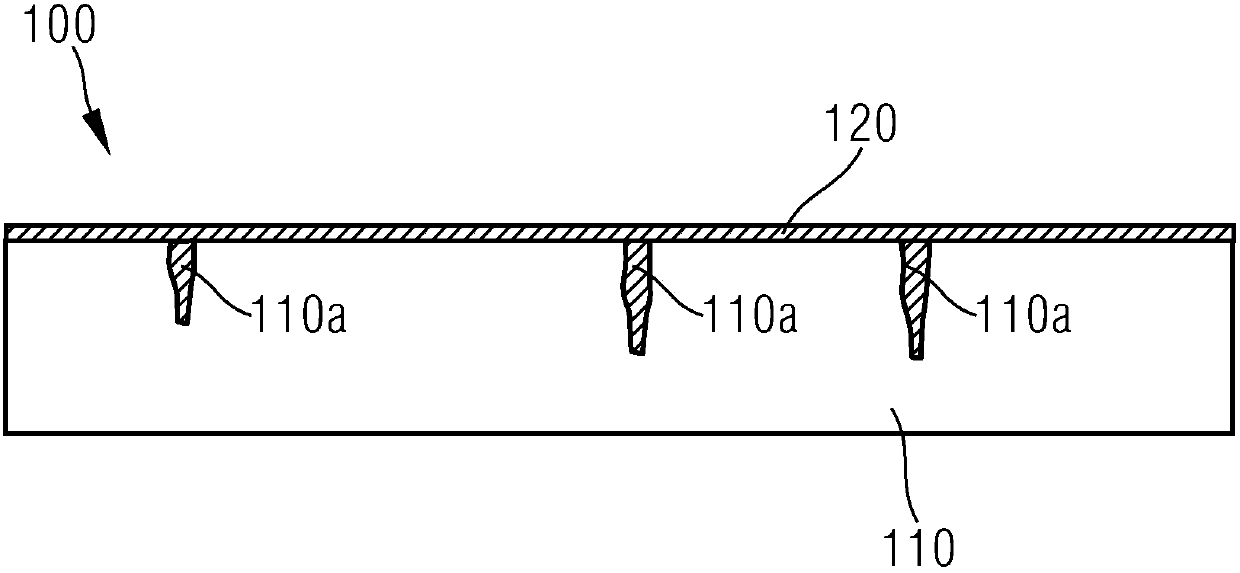

[0020] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0021] The invention provides a method for improving the quality of the inner surface of a 3D printed part, which includes the following steps:

[0022] First, step S1 is executed to perform 3D printing according to a predetermined model to obtain a printed finished part. Wherein, the selective laser melting equipment includes a molding cylinder, in which a piston is arranged, and the piston can move up and down. A printing plate is arranged on the piston, and metal powder is placed in the space on the printing plate. The piston adjusts the printing space in the forming cylinder by moving up and down. Selective laser melting equipment performs laser scanning on the metal powder, breaks the metal powder into a powder matrix, and continues to laser scan the powder matrix until the powder matrix is sintered from the bottom up into a pre-printed sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com