Core needle and core pack inner hole expanding mechanism

A technology of core needle and core package, which is applied in the field of core package inner hole expansion mechanism, can solve the problems of automatic shell welding, center hole diaphragm damage, uneven heating of rolling needle, etc., to achieve compact structure, not easy to deform and rebound, and guarantee The effect of uniformity and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

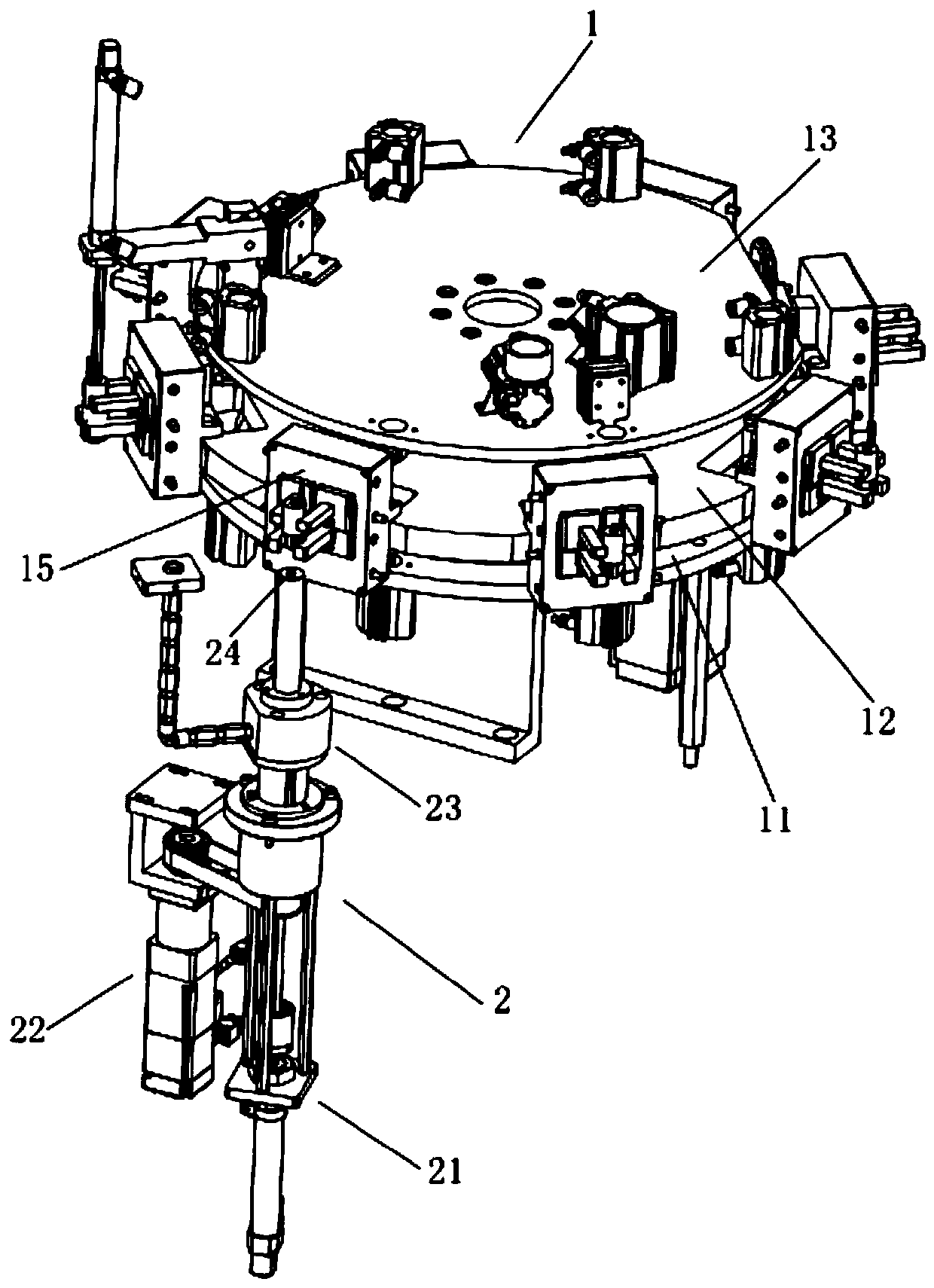

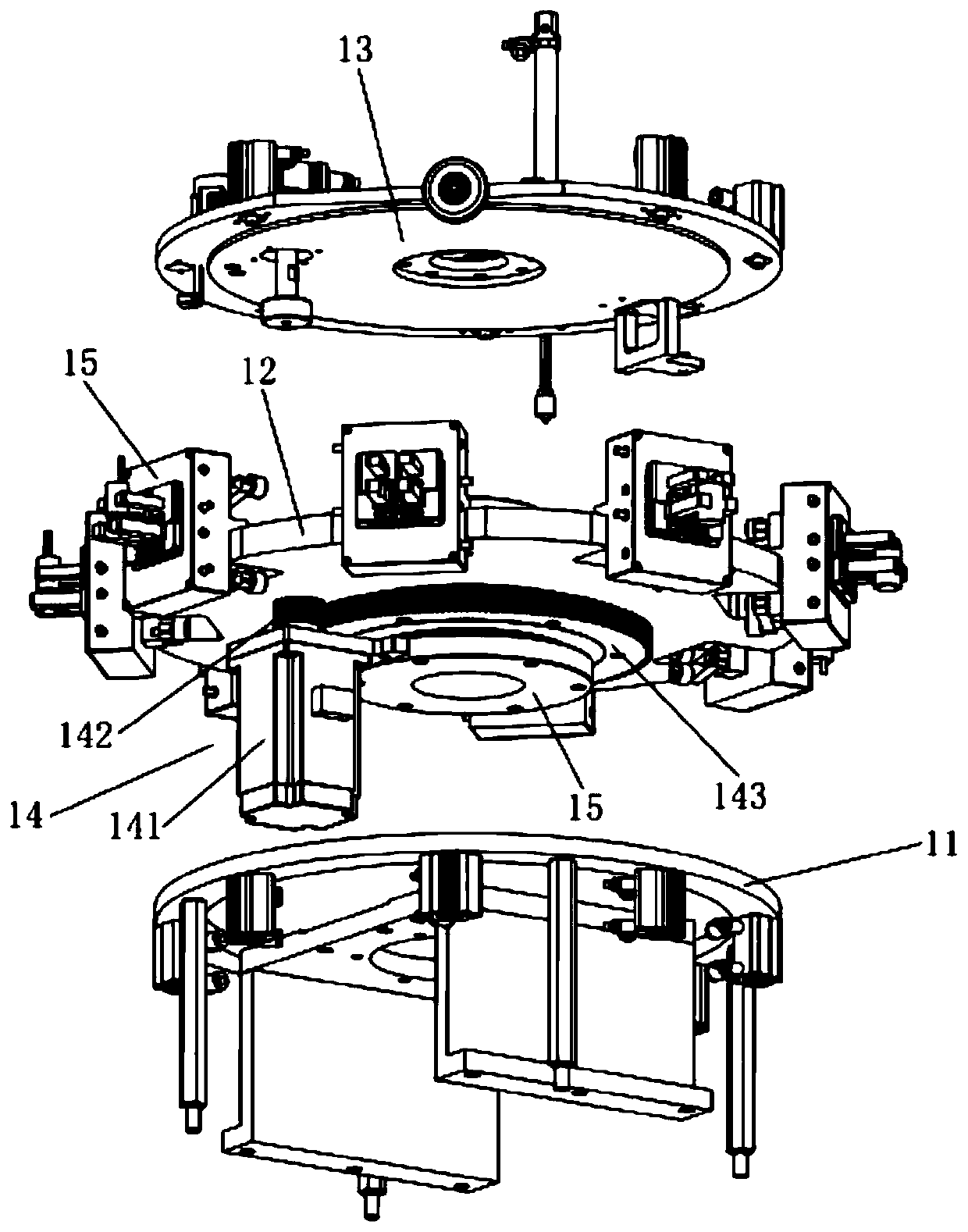

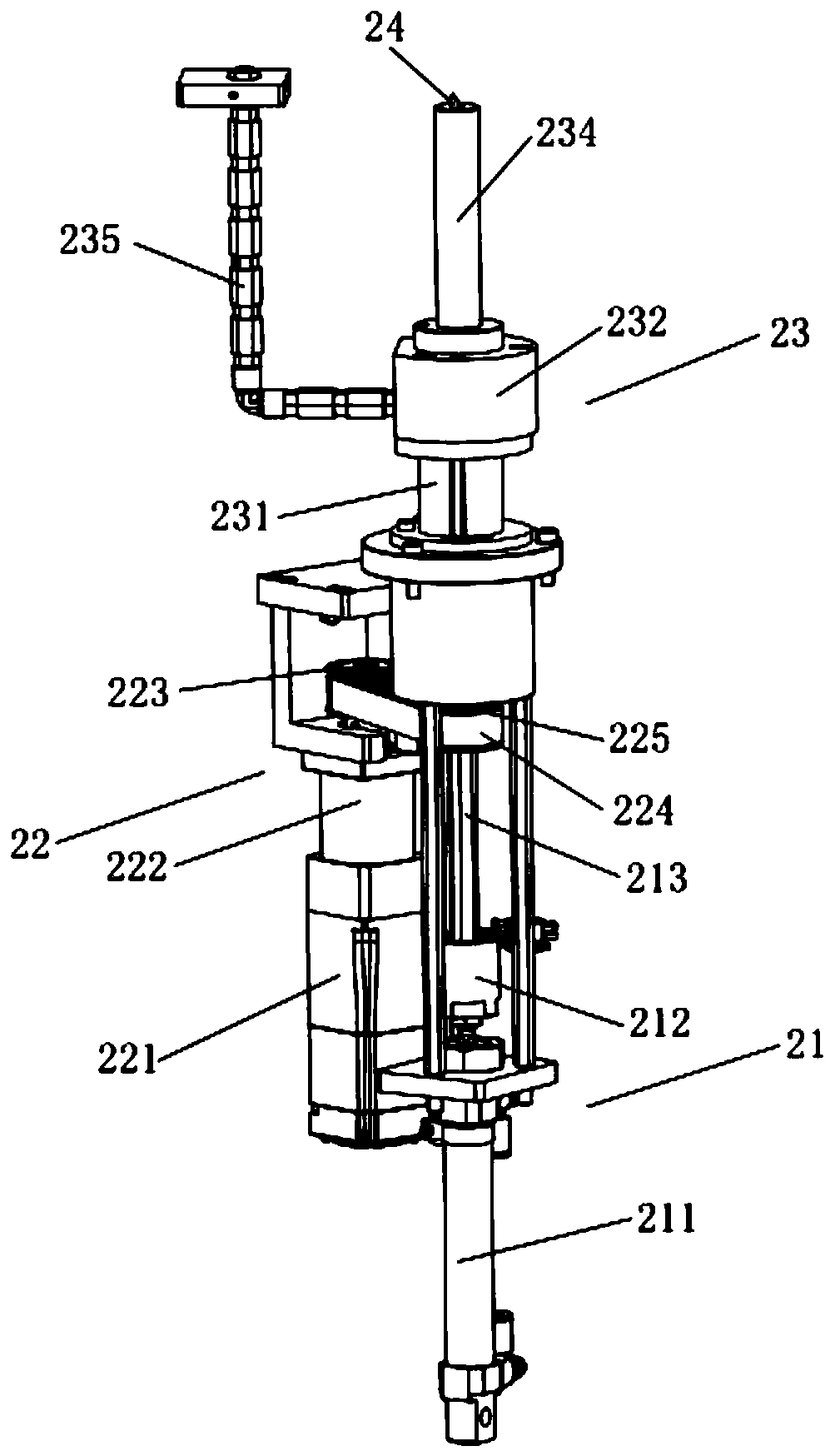

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, in this embodiment, the core package inner hole expansion mechanism used for reaming the center hole of the battery includes an automatic rotary feeding device 1 and an inner hole expanding device 2. The device 1 clamps and feeds the material, and the center hole of the cell is reamed by the inner hole reaming device 2 . combine figure 2 As shown, the automatic rotating feeding device 1 includes a lower fixed plate assembly 11, a turntable 12, an upper fixed plate assembly 13, a gear rotating assembly 14 and several clamping assemblies 15, and the lower fixed plate assembly 11 is used to install and fix various parts , the lower fixed disk assembly 11 is used as a part of the frame. The rotating disk 12 and the upper fixed disk assembly 13 are sleeved and fixed on the same rotating disk shaft 16 , and the rotating disk 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com