Double-layer cylinder flow arranging type small-bore gun muzzle brake and manufacturing method thereof

A double-layer cylinder and brake technology, applied in the field of firearms and artillery, can solve the problems of muzzle shock wave hazard benefit, limited freedom, time-consuming manufacturing, etc., to reduce the flow of gunpowder gas, reduce recoil, and improve the return efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

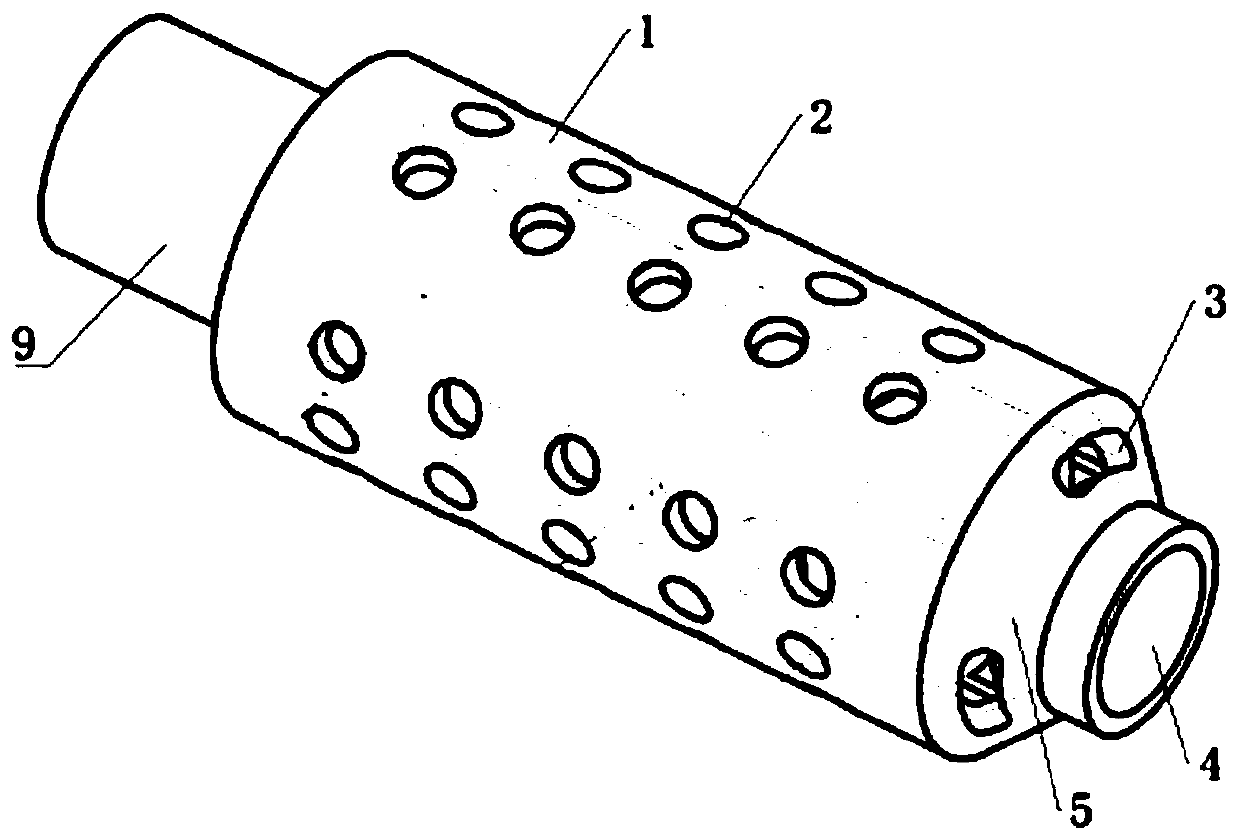

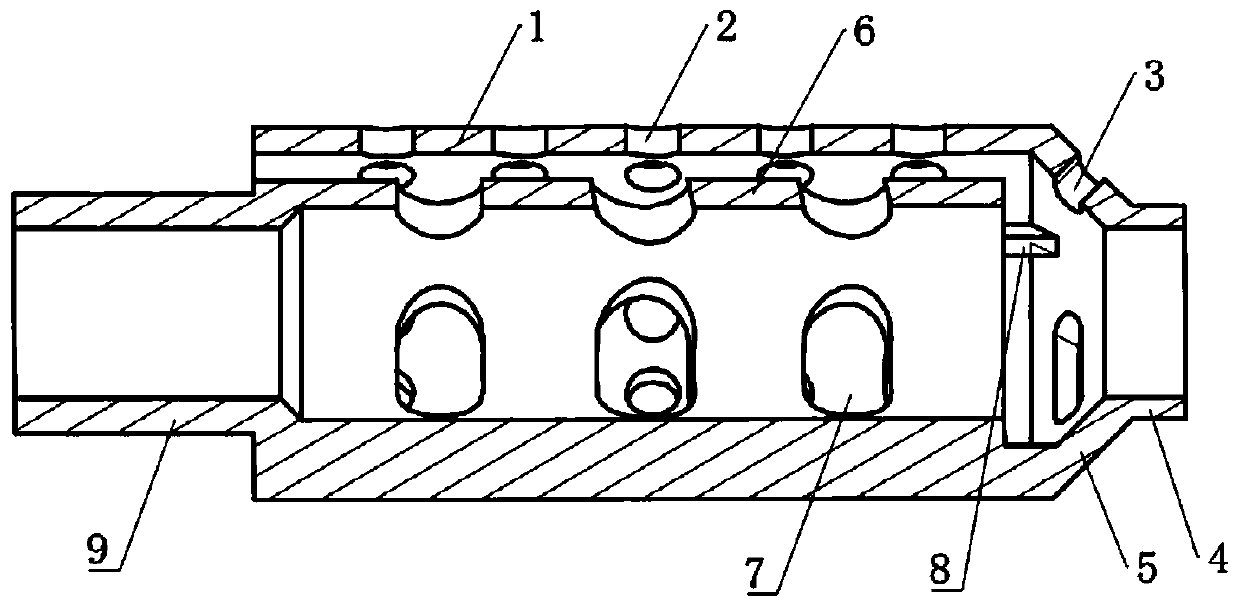

[0038] combine figure 1 , figure 2 , a double-layer rectification type 3D printed small-caliber muzzle brake of the present invention is an integrated centrosymmetric structure, with an inner cylinder 6 and an outer sleeve 1 .

[0039] Taking the direction pointed by the muzzle as the positive reference, the inner surface of the bottom end 9 of the inner layer cylinder is provided with a connecting thread, which is connected with the outer surface thread of the gun barrel head to form a thread pair.

[0040] Inner layer cylinder 6 head inner diameters are not less than the barrel caliber. The circumferential wall of the head of the inner cylinder 6 is provided with multiple groups of waist-shaped side holes 7 distributed symmetrically about the center of the gun axis. Each group of waist-shaped side holes 7 is equidistantly distributed along the gun axis direction with a plurality of waist-shaped side holes with different reclining angles and areas. In every group of waist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com