Low-nitrogen swirling burner based on out-phase reduction of superfine pulverized coal and transformation method

A technology of swirl burner and fine coal powder, which is applied in the direction of combustion method, burner for burning powder fuel, burner, etc., can solve the problems of high price of natural gas, less application, and scarce quantity, and achieve the increase of NOx reduction efficiency, Effect of reducing fuel-type NOx and short internal diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

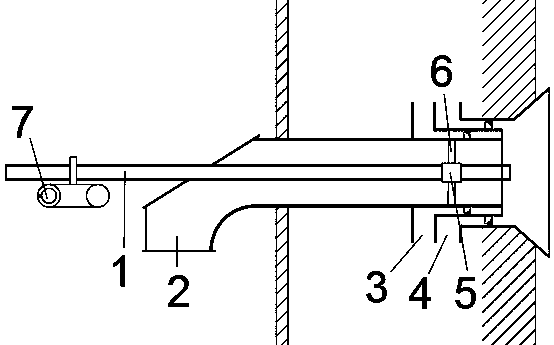

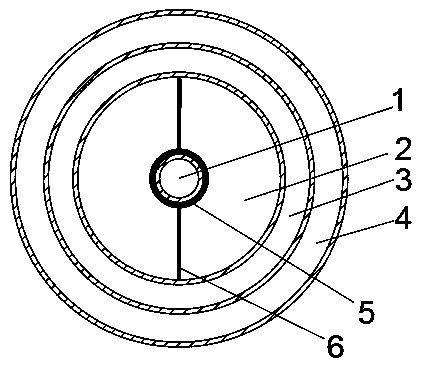

[0030] combine figure 1 , figure 2 , a low-nitrogen cyclone burner for heterogeneous reduction of ultra-fine pulverized coal in this embodiment, mainly consists of a central ultra-fine pulverized coal tube 1, a smooth anti-wear sleeve 5, a sleeve fixing device 6, and a tail leak-proof treatment device, etc. composition. A central ultra-fine pulverized coal pipe is installed in the axial central air duct of the swirl burner to transport ultra-fine coal powder into the furnace. Outer secondary air channel 4, and the central superfine pulverized coal pipe can adjust the relative position of the central superfine pulverized coal nozzle and the outlet of the primary air duct through the handwheel 7.

[0031] In this embodiment, the initial mark position of the handwheel rotation is recorded when the central superfine pulverized coal nozzle is flush with the outlet of the primary air duct. During the operation of the burner, the position of the central superfine pulverized coal p...

specific Embodiment approach 2

[0033] Specific implementation mode two: as Figure 1~2 As shown, this embodiment discloses a specific embodiment one, a modification method of a superfine pulverized coal heterogeneous reduction low-nitrogen swirl burner described in the specific embodiment, and the modification method includes the following steps:

[0034] Step 1: Weld the sleeve fixing device with wear-resistant material on the side of the existing swirl burner close to the furnace;

[0035] Step 2: Weld a smooth wear-resistant sleeve with an inner diameter larger than the outer diameter of the central ultra-fine pulverized coal pipe on the sleeve fixing device;

[0036] Step 3: Insert the central ultra-fine pulverized coal tube that has undergone anti-wear treatment into the swirl burner, and pass through the sleeve installed in step 2, and make a good connection between the central ultra-fine pulverized coal tube and the tail insertion area of the swirl burner. Anti-leakage measures, and at the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com