Method for improving the fiber strength of waste paper with low lignin content by using cellulase/amino acid modification and paper prepared by the method

A technology of cellulase and waste paper fiber, which is applied in the treatment of secondary cellulose fiber, paper, and fiber raw materials. It can solve the problem that the effect of cellulase treatment is not particularly obvious, and achieve the improvement of paper physical properties and carboxyl content. Increase and improve the effect of physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

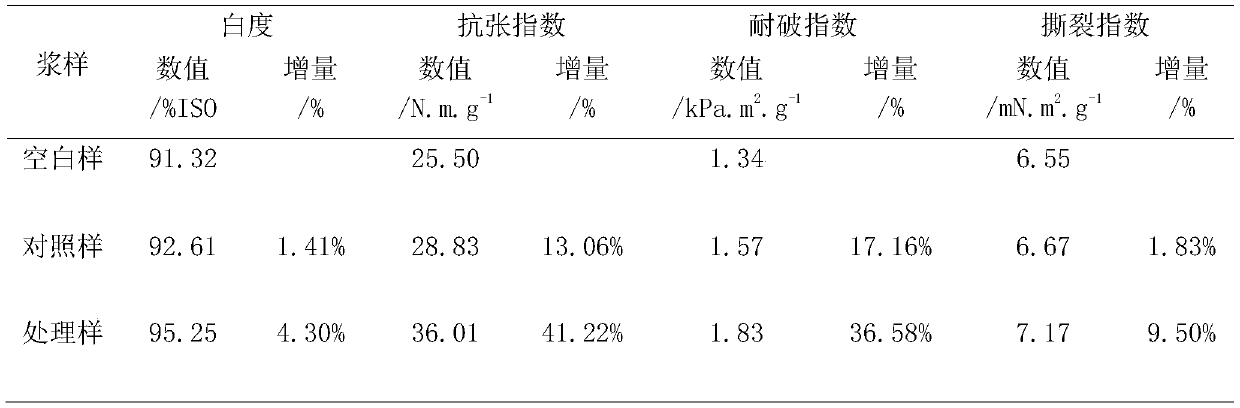

Embodiment 1

[0031] A kind of method that utilizes cellulase / amino acid modification to promote the waste paper fiber strength of low lignin content that embodiment 1 provides (the processing method of processing sample in embodiment 1), comprises the steps:

[0032] (1) Take 30 grams of absolutely dry office waste paper (MOW) and cut into pieces, soak in water, then pulp the waste paper in a high-consistency pulper, and the speed of pulping is set to 320r / min, , the pulping concentration is controlled to be 10wt%, the temperature is set to 50°C, and the pulping time is 20min; after the pulping is completed, the pulp is collected and the pulp concentration is adjusted to 8wt%, to obtain waste paper pulp;

[0033] (2) the waste paper pulp described in step (1) is adjusted to a pH value of 7.0 with disodium hydrogen phosphate / citric acid buffer solution, then in the waste paper pulp, cellulase is added (the addition of cellulase is 3U / g, i.e. Every gram of waste paper pulp absolute dry mass ...

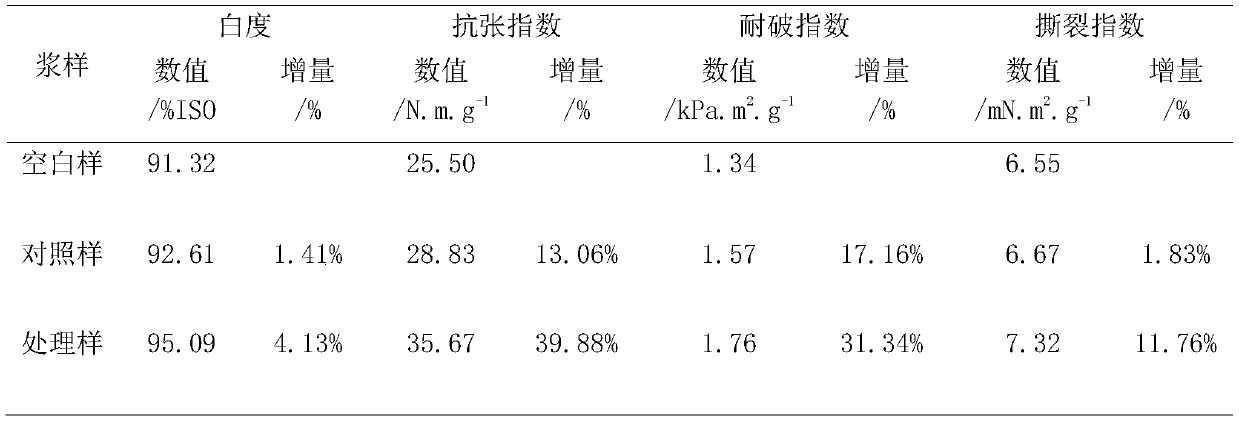

Embodiment 2

[0045] A kind of method (the processing method of treatment sample in embodiment 2) that utilizes cellulase / amino acid modification to promote low lignin content waste paper fiber strength that embodiment 2 provides, comprises the following steps:

[0046] (1) Weigh 30 grams of dry office waste paper and cut it into pieces, soak it in water, and then pulp the waste paper in a high-consistency pulper. The speed of pulping is set at 320r / min, and the pulping concentration The control is 10wt%, the temperature is set to 50°C, and the pulping time is 20min; after the pulping is completed, the pulp is collected and the pulp concentration is adjusted to 8wt% to obtain waste paper pulp;

[0047] (2) the waste paper pulp described in the step (1) is adjusted to a pH value of 7.0 with disodium hydrogen phosphate / citric acid buffer solution, then in the pulp, add cellulase (the addition of cellulase is 3U / g, i.e. every Add 3U) and glutamic acid (the quality that glutamic acid adds is re...

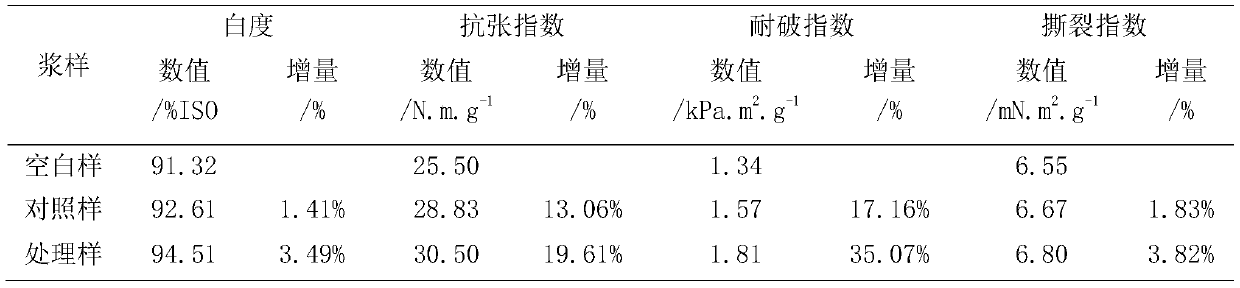

Embodiment 3

[0059] A kind of method (the processing method of processing sample in embodiment 3) that utilizes cellulase / amino acid modification to improve low lignin content waste paper fiber strength that embodiment 3 provides, comprises the following steps:

[0060] (1) Weigh 30 grams of dry office waste paper and cut it into pieces, soak it in water, and then pulp the waste paper in a high-consistency pulper. The speed of pulping is set to 300r / min, and the pulping concentration The control is 10wt%, the temperature is set at 40°C, and the pulping time is 25min. After the pulping was finished, the pulp was collected and the pulp concentration was adjusted to be 8wt%, so as to obtain waste paper pulp;

[0061] (2) the waste paper pulp described in step (1) is adjusted to a pH value of 6 with disodium hydrogen phosphate / citric acid buffer solution, then in the waste paper pulp, cellulase is added (the addition of cellulase is 4U / g, i.e. Add 4U) and 2wt% glycine per gram of dry pulp (th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com