Technology and device for pyrolyzing biogas residues by molten salt and preparing phenol compounds

A technology of phenolic compounds and biogas residues, which is applied in the direction of educts, petroleum industry, special forms of carbonization, etc., can solve the problems of small-scale biogas residues that cannot meet large-scale processing, water and soil pollution, and bacterial transmission, etc., and achieve pyrolysis effect Better, solve energy consumption problems, and respond quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

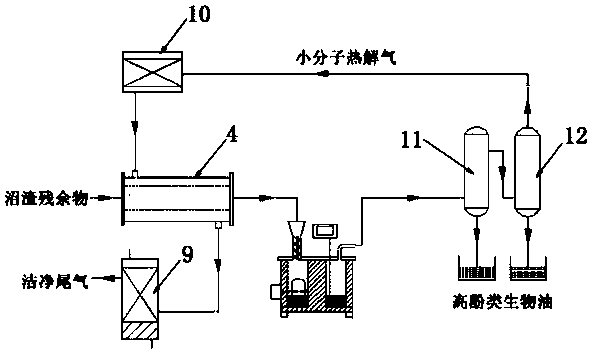

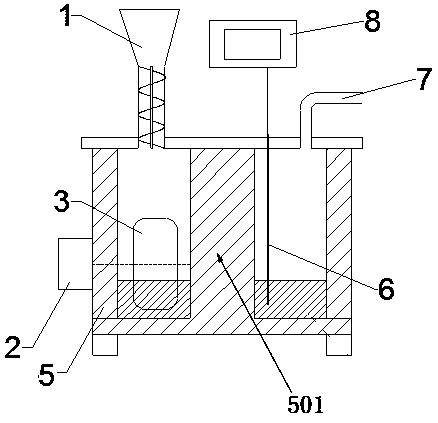

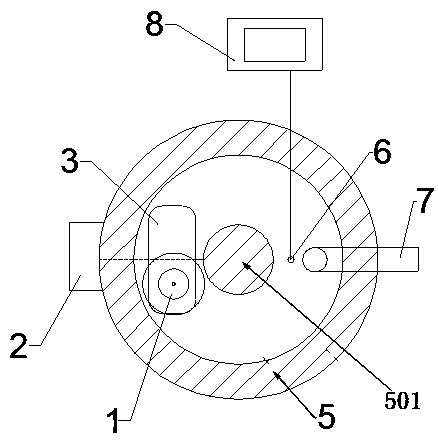

[0030] Example: Control Figure 1~3

[0031] A device for pyrolyzing biogas residue with molten salt to prepare phenolic compounds, including a biogas residue crushing and feeding device, a thermal cracking reaction device, and a product collection and processing device.

[0032] The biogas residue crushing and feeding device comprises a pulverizer, a drying box 4 and a screw feeder 1 connected in sequence, and the discharge port of the screw feeder 1 is connected to the biogas residue inlet at the top of the pyrolysis reactor 5 by Pipe connection; the screw feeder 1 is a feeder that can continuously rotate while ensuring airtightness, and can uniformly and uninterruptedly transport the residue of biogas residue into the molten salt pyrolysis reactor 5 . The drying box 4 includes a drying box body and a heat exchange interlayer sheathed on the outside of the drying box body. The heat exchange interlayer is provided with a hot fluid inlet and a hot fluid outlet.

[0033] The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com