Composite catalyst for PET degradation and PET degradation method

A catalyst, composite technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

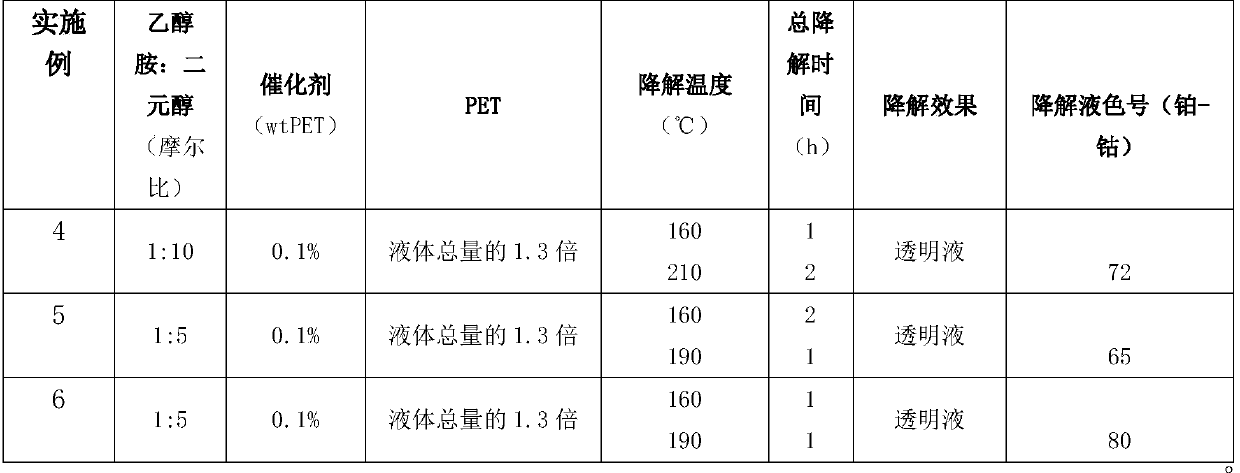

Examples

Embodiment 1

[0023] A composite catalyst for PET degradation comprises solid organotin and solid inorganic tin, wherein, in parts by weight, the ratio of solid organotin to solid inorganic tin is 2:1. The solid organotin is monobutyltin oxide, and the solid inorganic tin is stannous chloride.

[0024] The preparation method of the catalyst is as follows: weigh according to the weight ratio, and then mix the two evenly.

Embodiment 2

[0026] A composite catalyst for degradation of PET comprises solid organic tin and solid inorganic tin, wherein, in parts by weight, the ratio of solid organic tin to solid inorganic tin is 2.5:1. The solid organotin is monobutyltin oxide, and the solid inorganic tin is stannous chloride.

[0027] The preparation method of catalyst is the same as embodiment 1.

Embodiment 3

[0029] A composite catalyst for PET degradation comprises solid organotin and solid inorganic tin, wherein, in parts by weight, the ratio of solid organotin to solid inorganic tin is 1.5:1. The solid organotin is monobutyltin oxide, and the solid inorganic tin is stannous chloride.

[0030] The preparation method of catalyst is with embodiment 1:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com