Modified vanadium tetrasulfide Fenton catalyst and preparation method and application thereof

A vanadium tetrasulfide Fenton and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low activity, low utilization rate of hydrogen peroxide, poor stability, etc., to achieve Simple preparation method, excellent catalytic performance, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

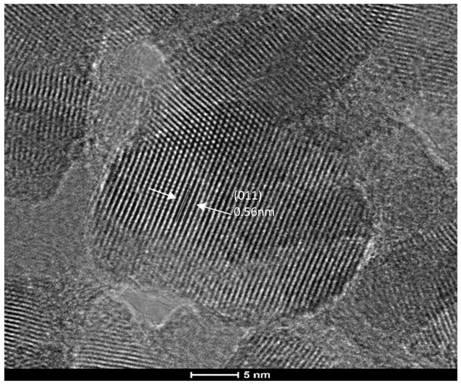

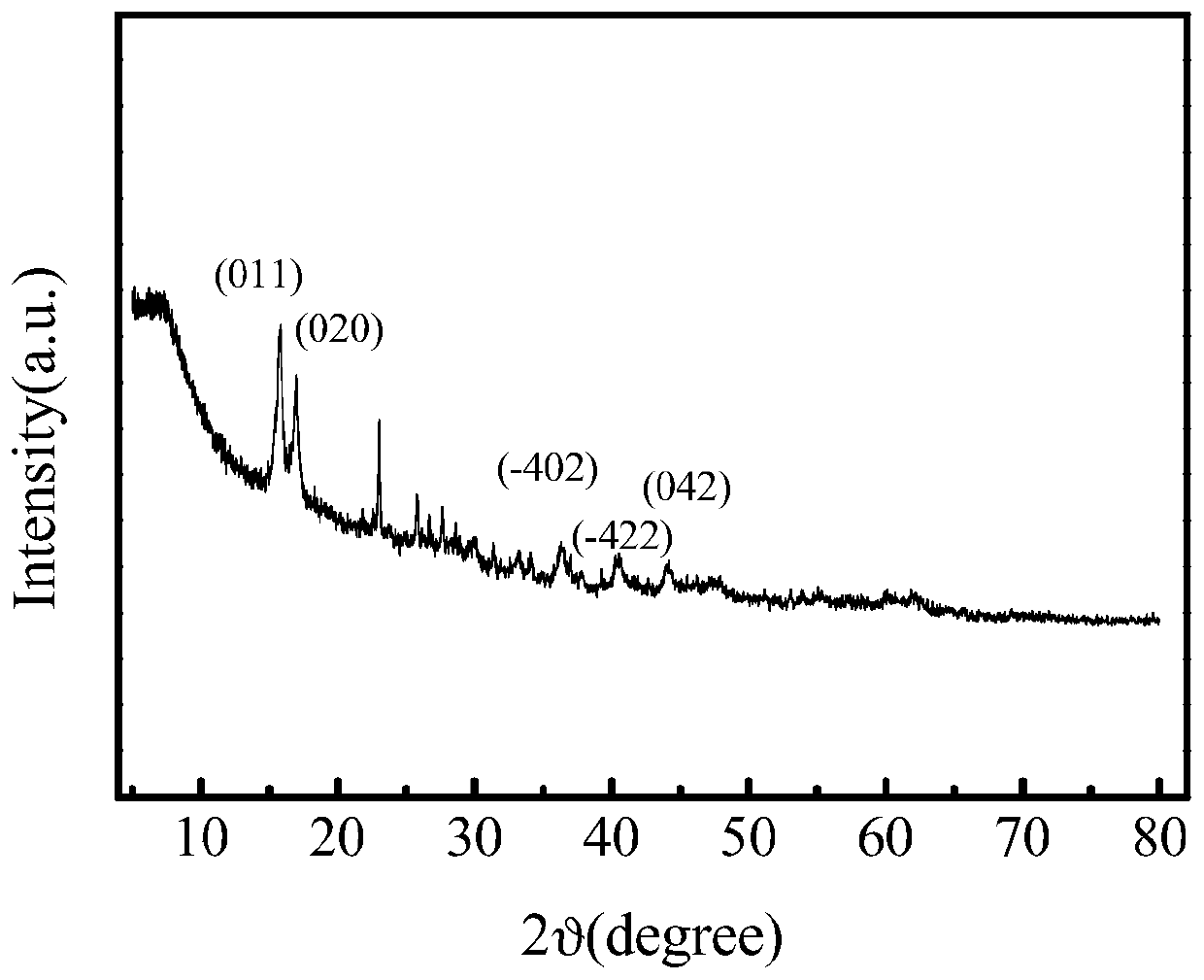

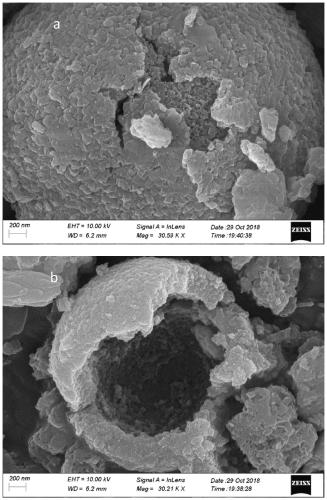

[0039] The preparation method of a kind of modified vanadium tetrasulfide Fenton catalyst as the embodiment of the present invention, described method comprises the following steps:

[0040] (1) Weigh 0.5g of cetylpyridinium bromide polymer into 30mL of deionized water, stir to dissolve, add 0.35g of ammonium metavanadate, heat to 60°C, and stir for 20min to obtain solution A;

[0041] (2) Weigh 1.13g of thioacetamide and add it to 30mL of ethylene glycol, stir and dissolve to obtain solution B, mix solution A and solution B, and stir at 60°C for 30min to obtain solution C;

[0042] (3) Put solution C in a 100mL autoclave, put the autoclave into an oven and react at 160°C for 12h;

[0043] (4) After cooling, take out the suspension in the reactor, centrifuge and wash the obtained solid with ethanol and deionized water alternately for a total of 6 times, dry the final solid in a 60°C oven for 10 hours, and grind After obtaining described modified vanadium tetrasulfide Fenton c...

Embodiment 2

[0050] The application of a modified vanadium tetrasulfide Fenton catalyst in the degradation of organic pollutants in water as an embodiment of the present invention, the method may further comprise the steps:

[0051] (1) 0.03g of the CNO-VS prepared in Example 1 4 Put the catalyst into 50mL of 10mg / L organic pollutant solution, add 50μL of hydrogen peroxide solution at the same time, and start the Fenton reaction with continuous stirring in the water bath at 35°C;

[0052] The organic pollutants are respectively: rhodamine B (RhB), methylene blue (MB), acid orange 7 (AO7), bisphenol A (BPA), 2-chlorophenol (2-CP) and ciprofloxacin (CIP ).

[0053] Samples were taken at different time points to determine the concentration of pollutants.

[0054] The results of the degradation rate as Figure 5 shown, for CNO-VS 4 Catalyst degradation curves for RhB, MB, AO7, BPA, 2-CP, CIP. In 90 minutes, the degradation rate of BPA and 2-CP reached 100%, the degradation rate of RhB rea...

Embodiment 3

[0056] The application of a modified vanadium tetrasulfide Fenton catalyst in the degradation of organic pollutants in water as an embodiment of the present invention, the method may further comprise the steps:

[0057] (1) 0.03g of the CNO-VS prepared in Example 1 4 Put the catalyst into 50mL of 10mg / L RhB solution, add 50μL of hydrogen peroxide solution at the same time, and start the Fenton reaction with continuous stirring in the water bath at 35°C;

[0058] (2) react for 90min, detect the concentration of RhB;

[0059] (3) CNO-VS after step (2) 4 After the catalyst is separated and dried, put it into 50mL of RhB solution, and add 50μL of hydrogen peroxide solution at the same time, in a water bath at 35°C, start the Fenton reaction for 90min with continuous stirring, and detect the concentration of RhB;

[0060] (4) Repeat step (3).

[0061] Figure 6 Be the CNO-VS that embodiment makes 4 Catalyst recycling activity evaluation diagram for RhB degradation. It can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com