Triangular vibration grinding process for aluminum alloy part

An aluminum alloy, triangular technology, applied in the field of triangular vibration grinding process, can solve the problems of affecting product quality, high maintenance cost, incomplete grinding, etc., to achieve the effect of ensuring integrity and uniformity, high safety, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

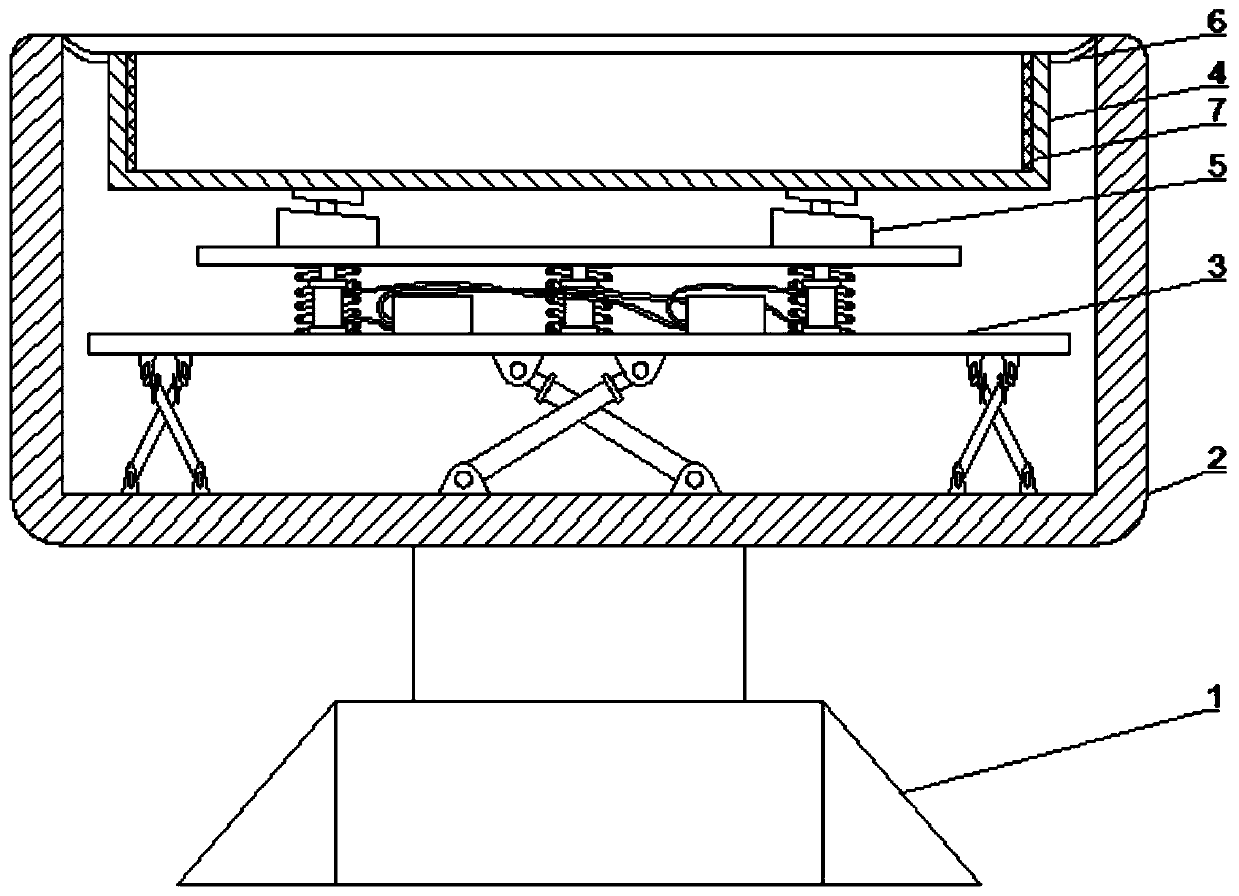

[0035] Such as figure 1 The shown triangular vibration grinding process for aluminum alloy parts includes: a base 1, a shell 2, an adjustment plate 3, a grinding bucket 4, a vibration mechanism 5 and a protective layer 6, and the base 1 is provided with a shell 2. An adjustment plate 3 is arranged inside the housing 2, a vibration mechanism 5 is arranged on the adjustment plate 3, a grinding bucket 4 is arranged on the vibration mechanism 5, and a protective layer 6 is arranged on the edge of the grinding bucket 4, One side of the protective layer 6 is fixed on the grinding bucket 4, and the other side of the protective layer 6 is fixed on the housing 2, and the protective layer 6 is made of a flexible material; the vibrating mechanism 5 is provided with a plurality of The vibration mechanism 5 is arranged at the edge of the bottom of the grinding bucket 4;

[0036] It also includes a grinding step, which specifically includes the following steps: grinding, the vibration mech...

Embodiment 2

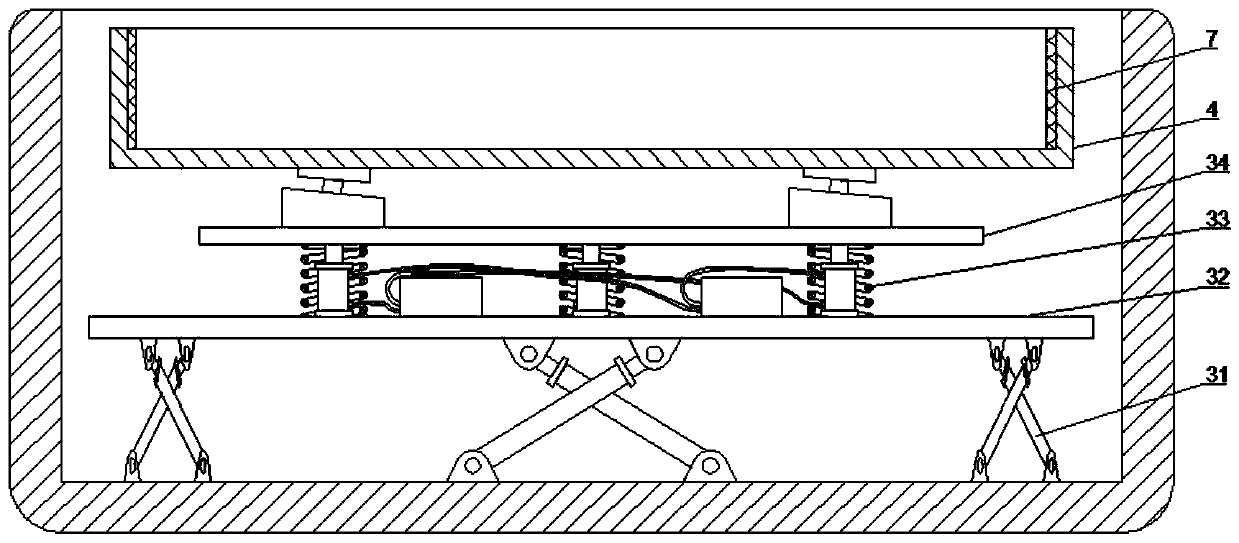

[0045] Such as figure 2 and 3 The shown triangular vibration grinding process for aluminum alloy parts includes: a base 1, a shell 2, an adjustment plate 3, a grinding bucket 4, a vibration mechanism 5 and a protective layer 6, and the base 1 is provided with a shell 2. An adjustment plate 3 is arranged inside the housing 2, a vibration mechanism 5 is arranged on the adjustment plate 3, a grinding bucket 4 is arranged on the vibration mechanism 5, and a protective layer 6 is arranged on the edge of the grinding bucket 4, One side of the protective layer 6 is fixed on the grinding bucket 4, and the other side of the protective layer 6 is fixed on the housing 2, and the protective layer 6 is made of a flexible material; the vibrating mechanism 5 is provided with a plurality of The vibration mechanism 5 is arranged at the edge of the bottom of the grinding bucket 4;

[0046] It also includes a grinding step, which specifically includes the following steps: grinding, the vibrat...

Embodiment 3

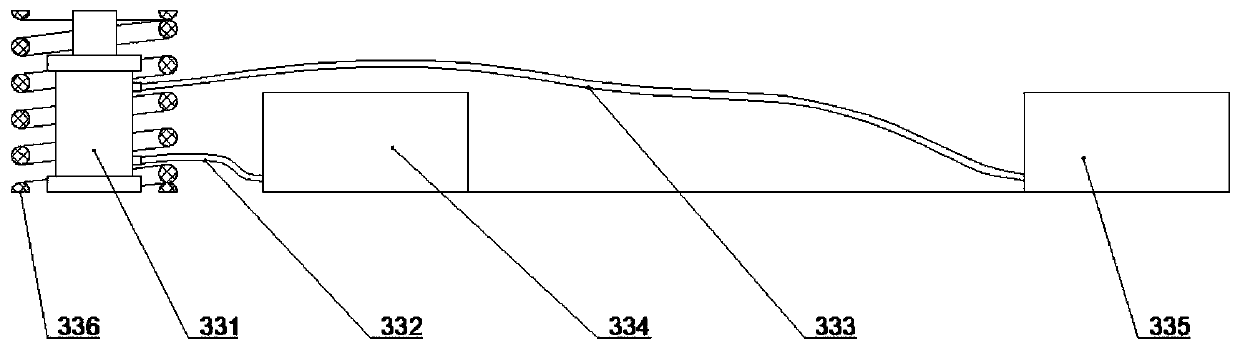

[0052] Such as Figure 4 , 5 A triangular vibration grinding process for aluminum alloy parts shown in and 6 includes: a base 1, a housing 2, an adjustment plate 3, a grinding bucket 4, a vibrating mechanism 5 and a protective layer 6, and the base 1 is provided with Housing 2, an adjustment plate 3 is arranged inside the housing 2, a vibration mechanism 5 is arranged on the adjustment board 3, a grinding bucket 4 is arranged on the vibration mechanism 5, and a protective layer is arranged on the edge of the grinding bucket 4 6. One side of the protective layer 6 is fixed on the grinding bucket 4, and the other side of the protective layer 6 is fixed on the housing 2. The protective layer 6 is made of flexible materials; the vibration mechanism 5 is provided with multiple, The vibration mechanism 5 is arranged at the bottom edge of the grinding bucket 4;

[0053] It also includes a grinding step, which specifically includes the following steps: grinding, the vibration mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com