Red light semiconductor laser based on GexSi<1-x> variable lattice constant matrix

A lattice constant, laser technology, applied in semiconductor lasers, lasers, laser parts and other directions, can solve the problems of poor device characteristics, high light decay, complex generation and migration, etc., to achieve improved output power and photoelectric conversion efficiency, reliable Good performance and the effect of reducing tensile strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

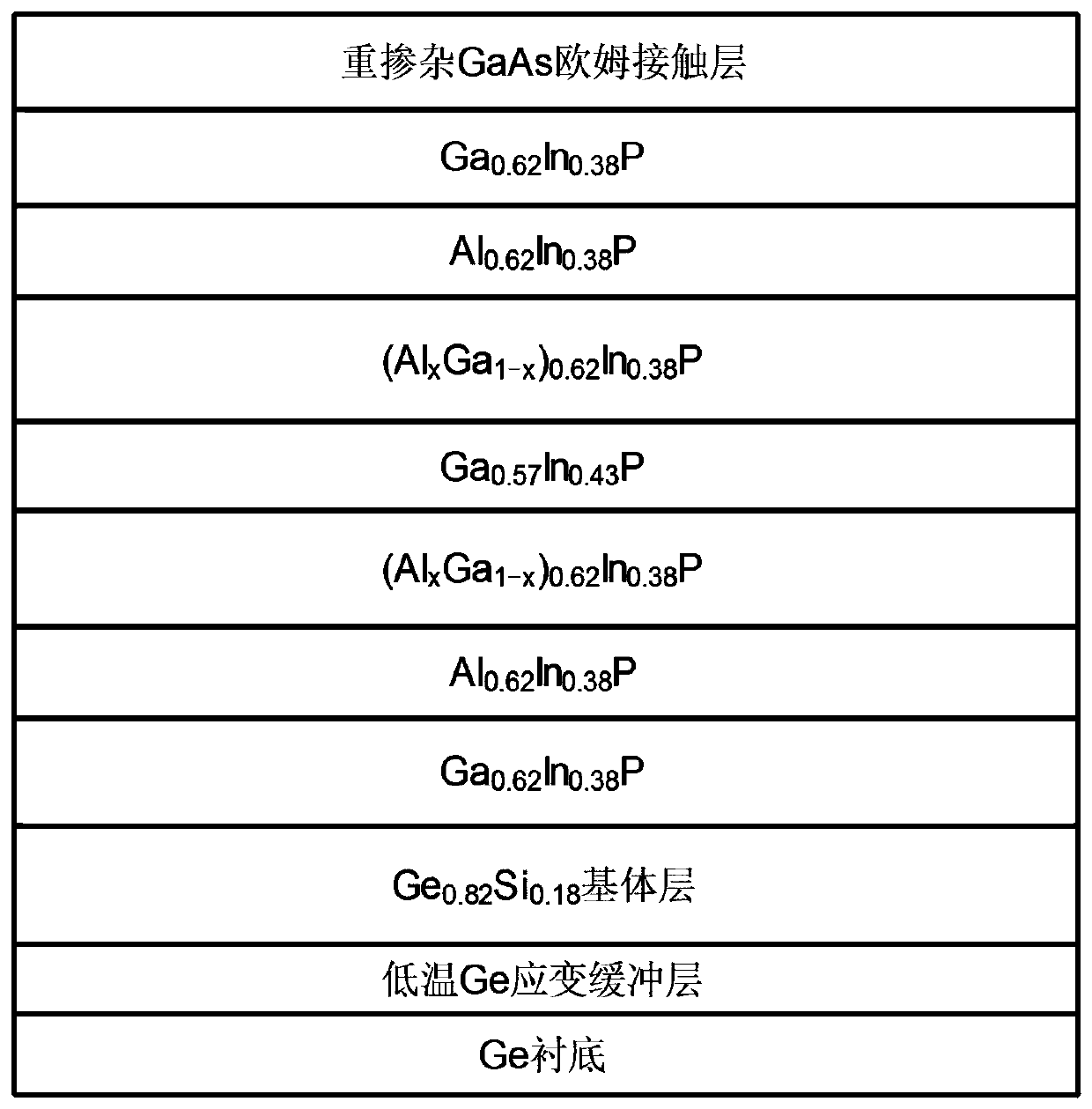

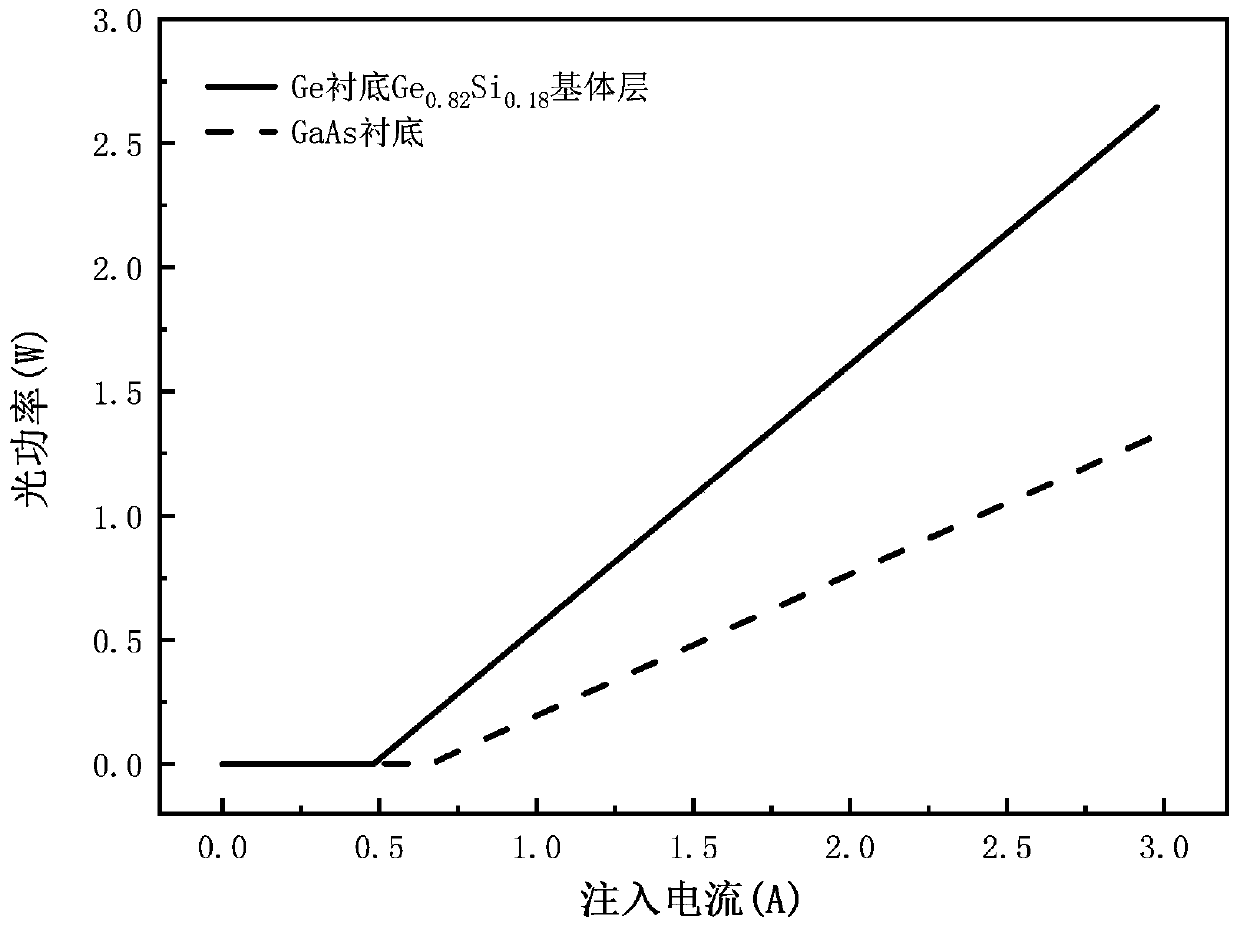

[0036] refer to figure 2 , is based on the Ge substrate Ge of the embodiment 1 of the present invention x Si 1-x Schematic diagram of the structure of the 620nm red semiconductor laser in the substrate layer. In Example 1, the cavity length of the entire semiconductor laser is 1.5 mm, the stripe width of the current injection zone is 120 μm, and the cavity surface is not coated. The device structure is a Ge substrate, a low-temperature Ge strained buffer layer, and a Ge 0.82 Si 0.18 Base layer, Ga 0.62 In 0.38 P buffer layer, Al 0.62 In 0.38 P lower confinement layer, (Al x Ga 1-x ) 0.62 In 0.38 P lower waveguide layer, (Al x Ga 1-x ) 0.62 In 0.38 P upper waveguide layer, Al 0.62 In 0.38 Confinement layer on P, Ga 0.62 In 0.38 P barrier layer, heavily doped GaAs ohmic contact layer. where the quantum well region is compared to Ge 0.82 Si 0.18 The substrate lamination strain is 0.4% Ga 0.57 In 0.43 P layer, the thickness of the well is 8nm.

[0037] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com