A fast charging method based on high temperature resistant lithium ion battery

A lithium-ion battery and fast charging technology, applied in the field of lithium-ion batteries, can solve problems such as failure of fast charging function, thermal runaway, reduction of charging power, etc., and achieve the effect of reducing charging waiting time, wide operating temperature range, and avoiding potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

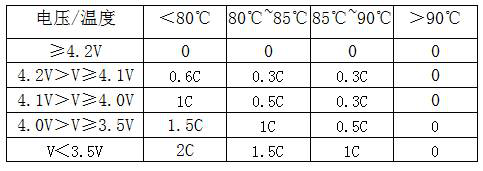

[0047] Taking the current 1C of normal fast charging as an example, during charging, the battery management system BMS (hereinafter referred to as BMS) collects the temperature and voltage data of the battery in real time, and adjusts the charging current according to the real-time voltage and temperature data, for example:

[0048] When the voltage is below 3.5V:

[0049] a) The charging current is 2C when the temperature is below 80°C;

[0050] b) The charging current is 1.5C when the temperature is above 80°C and below 85°C;

[0051] c) The charging current is 1C when the temperature is above 85°C and below 90°C;

[0052] d) Charging is not allowed when the temperature is above 90°C.

[0053] When the voltage is above 3.5V and below 4.0V:

[0054] a) The charging current is 1.5C when the temperature is below 80℃;

[0055] b) The charging current is 1C when the temperature is above 80°C and below 85°C;

[0056] c) The charging current is 0.5C when the temperature is abo...

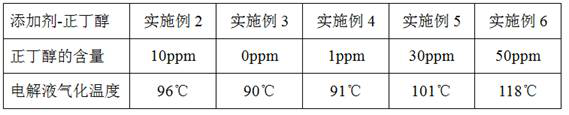

Embodiment 2

[0073] This embodiment provides a method for preparing a high temperature resistant lithium-ion battery, the steps are as follows:

[0074] 1. Electrolyte preparation: Prepare the electrolyte in the glove box, which is filled with nitrogen with a purity of 99.999%, the moisture in the glove box is controlled at ≤5ppm, and the temperature is room temperature (23°C±1°C). Mix the solvent system with a mass ratio of DMC:DEC:EC=3:4:3 evenly, seal it, put it in the refrigerator until it cools down to 10°C, transfer it to the glove box, and then add it to LiPF 6 Fully mix to form a lithium salt molar concentration of 1mol / L in the non-aqueous electrolyte of the lithium battery, and then add n-butanol (CH 3 (CH 2 ) 3 OH), so that it contains 10ppm of n-butanol (CH 3 (CH 2 ) 3 OH) non-aqueous electrolyte, after uniform mixing, the non-aqueous lithium battery electrolyte is obtained.

[0075] 2. Preparation of lithium battery positive electrode: Prepare lithium battery positive el...

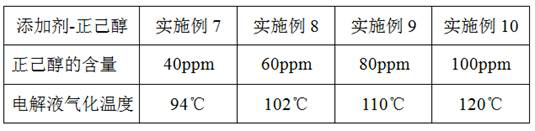

Embodiment 7-10

[0086] Replace n-butanol with additive n-hexanol.

[0087] The configuration and manufacturing method of Embodiment 7-10 are carried out with reference to the configuration and method of Embodiment 1.

[0088] As shown in table 2, each index and test result of the embodiment 7-10 that the present invention carries out are as shown in the table:

[0089] Table 2 is the comparison of electrolyte vaporization temperature data after adding different contents of n-hexanol additives

[0090]

[0091] The high-temperature-resistant lithium battery provided by the present invention, the electric vehicle produced by using the battery can have a wider working temperature range, and is more suitable for use in a high-temperature environment, which is specifically reflected in that it can carry out continuous high-current rapid charging in hot summer, improving The charging speed of electric vehicles reduces the waiting time for users to charge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com