Preparation method of high-stretchability polyaniline-based flexible electrically conductive hydrogel

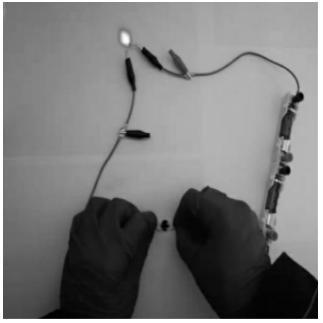

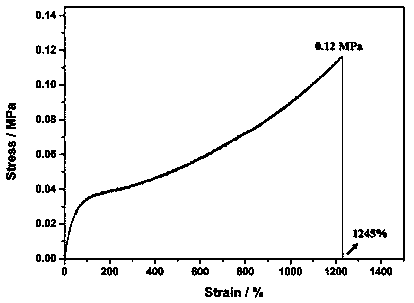

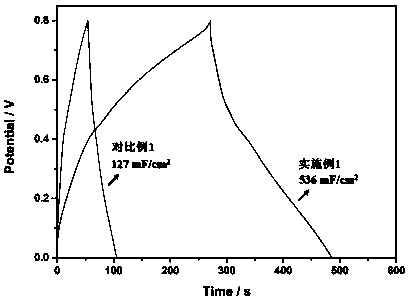

A polyaniline-based, flexible and conductive technology is used in the preparation of conductive functional polymer hydrogels and highly stretchable polyaniline-based flexible conductive hydrogels, which can solve problems such as inflexibility and restricting the use of flexible electronic devices. , to achieve the effect of promoting uniform distribution, excellent electrical conductivity and electrochemical performance, and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Dissolve 2.7g of NaOH solid in 20ml of deionized water, then slowly add 10g of acrylic acid in an ice-water bath to prepare a 50mol% neutralized acrylic acid aqueous solution; take 3ml of the above solution and mix it with 1g of acrylamide and 2ml of deionized water , stir until the solution is clear; then add 1ml 1wt% ammonium persulfate solution and 100μl 1wt% N,N'-methylenebisacrylamide solution in turn, stir until the solution is clear; pour the mixed solution into a plastic hose, seal it, ASH was prepared by reacting at 60°C for 4h.

[0028] (2) The ASH prepared in step (1) was swelled in a large amount of deionized water for 48 hours, then frozen at -18°C for 12 hours, and then thawed at room temperature for 4 hours to obtain a porous copolymer hydrogel.

[0029] (3) The porous copolymer hydrogel prepared in step (2) was placed in 30ml of 0.1mol / l aniline hydrochloride solution, stored in a vacuum environment for 3 hours, and then placed in a 0°C environment f...

Embodiment 2

[0039] (1) Dissolve 2.7g of NaOH solid in 20ml of deionized water, then slowly add 10g of acrylic acid in an ice-water bath to prepare a 50mol% neutralized acrylic acid aqueous solution; take 3ml of the above solution, mix with 1.3g of acrylamide and 2ml of deionized water Mix and stir until the solution is clear; then add 1ml 1wt% ammonium persulfate solution and 200μl 1wt% N,N'-methylenebisacrylamide solution in turn, stir until the solution is clear; pour the mixed solution into a plastic hose, seal , ASH was prepared by reacting at 60°C for 4h.

[0040] (2) The ASH prepared in step (1) was swelled in a large amount of deionized water for 48 hours, then frozen at -18°C for 12 hours, and then thawed at room temperature for 4 hours to obtain a porous copolymer hydrogel.

[0041] (3) The porous copolymer hydrogel prepared in step (2) was placed in 30ml of 0.1mol / l aniline hydrochloride solution, stored in a vacuum environment for 3 hours, and then placed in a 0°C environment f...

Embodiment 3

[0044] (1) Dissolve 2.7g of NaOH solid in 20ml of deionized water, then slowly add 10g of acrylic acid in an ice-water bath to prepare a 50mol% neutralized acrylic acid aqueous solution; take 3ml of the above solution and mix it with 1g of acrylamide and 2ml of deionized water , stir until the solution is clear; then add 1ml 1wt% ammonium persulfate solution and 300μl 1wt% N,N'-methylenebisacrylamide solution in turn, stir until the solution is clear; pour the mixed solution into a plastic hose, seal it, ASH was prepared by reacting at 60°C for 4h.

[0045] (2) The ASH prepared in step (1) was swelled in a large amount of deionized water for 48 hours, then frozen at -18°C for 12 hours, and then thawed at room temperature for 4 hours to obtain a porous copolymer hydrogel.

[0046] (3) The porous copolymer hydrogel prepared in step (2) was placed in 30ml of 0.2mol / l aniline hydrochloride solution, stored in a vacuum environment for 3 hours, and then placed in an environment of 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com