Preparation method for amino-terminated hyperbranched polysiloxane modified waterborne polyurethane

An amino-terminated hyperbranched, water-based polyurethane technology is applied in the field of preparation of amino-terminated hyperbranched polysiloxane-modified water-based polyurethane, and can solve the problems of low emulsion stability, severe phase separation, insufficient mechanical properties and cohesion, etc. , to achieve the effect of increasing interaction, good mechanical properties and bonding properties, and increasing the compatibility of two phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

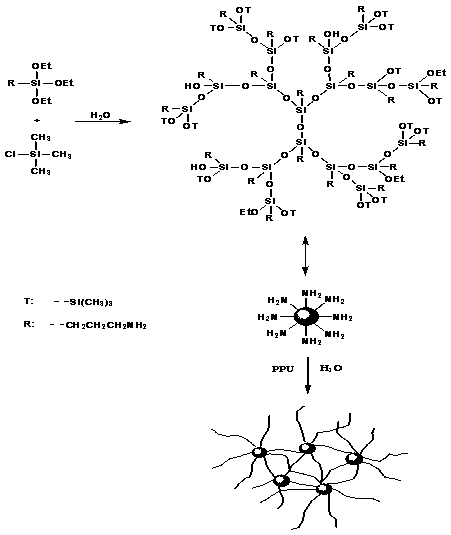

[0017] Step 1: HPSi-NH 2 preparation of

[0018] Add 3.6g of water to 22.14g of kh550, and add 20mL of ethanol to the system, slowly add 10.8g of TMCS dropwise under stirring conditions, and continuously reflux and stir at 50°C for 5h. After the reaction, adjust with sodium ethylate The pH of the system is neutral, and the solid salt generated is removed by high-speed centrifugation, and finally the small molecule ethanol is removed by a rotary evaporator to obtain the amino-terminated hyperbranched polysiloxane HPSi-NH 2 ;

[0019] Step 2: Preparation of HSiPU

[0020] First, add 20g of 1.4-butylene adipate (Mn=2000) and 8.89g of isophorone diisocyanate into a dry three-necked flask after vacuum dehydration, stir evenly, and add 3 drops of catalyst dilauric acid Dibutyltin, react at 75°C for 1.5h; add 1.45g of dimethylolpropionic acid, continue to react for 2.5h, until the -NCO content in the prepolymer remains constant, and obtain a polyurethane prepolymer (PPU);

[0021...

Embodiment 2

[0024] Step 1: HPSi-NH 2 preparation of

[0025] Add 1.8g of water to 22.14g of kh550, and add 20mL of ethanol, slowly add 10.8g of TMCS under stirring conditions, continuously reflux and stir at 50°C for 6h, adjust the pH of the solution to neutral with sodium ethoxide, and centrifuge The salt generated by the reaction was removed by a machine, and the small molecule ethanol was removed by a rotary evaporator to obtain the amino-terminated hyperbranched polysiloxane HPSi-NH 2 ;

[0026] Step 2: Preparation of HSiPU

[0027] First, add 10g of polytetrahydrofuran ether glycol (Mn=1000) and 5.22g of toluene diisocyanate into a dry three-necked flask after vacuum dehydration, stir evenly, add 3 drops of catalyst dibutyltin dilaurate, and react at 75°C 1.5h; add 1.33g dimethylolpropionic acid, continue to react for 2.5h, until the -NCO content in the prepolymer is constant, and obtain the polyurethane prepolymer PPU;

[0028] Then add 0.73g of butylamine to the obtained PPU an...

Embodiment 3

[0030] Step 1: HPSi-NH 2 preparation of

[0031] Add 3.6g of water to 22.14g of kh550, and add 30mL of ethanol, slowly add 15.0g of TMCS under stirring conditions, keep stirring and reflux reaction at 55°C for 5h, adjust the pH of the system to neutral with sodium ethoxide, and centrifuge The generated solid salt was removed by machine, and small molecule ethanol was removed by rotary evaporator to obtain amino-terminated hyperbranched polysiloxane HPSi-NH 2 ;

[0032] Step 2: Preparation of HSiPU

[0033] Add 20g of polyethylene glycol (Mn=2000) and 5.04g of hexamethylene diisocyanate after vacuum dehydration into a dry three-necked flask, stir evenly, add 3 drops of catalyst dibutyltin dilaurate, at 75°C React for 1 hour; add 1.60 g of dimethylolpropionic acid and continue the reaction for 2 hours until the -NCO content in the prepolymer remains constant to obtain PPU;

[0034] Then add 2.40g of pentaerythritol triacrylate to the obtained PPU, react at 80°C for 2h, cool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com