A kind of environment-friendly one-side surface reinforced stable wood and its preparation method

A stable, wood-based technology, applied in chemical instruments and methods, wood heating, wood treatment, etc., can solve problems such as the chord-radial shrinkage ratio of polluted modified wood, achieve synchronous improvement of hardness and dimensional stability, and improve stability Sexuality, the effect of simple realization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

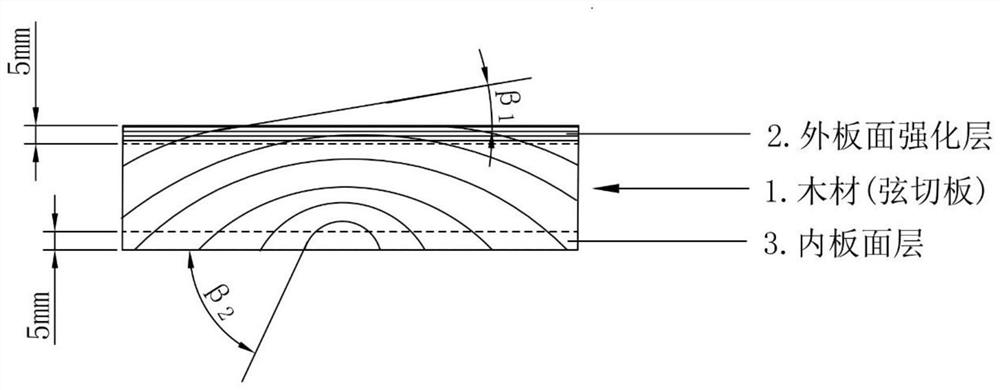

[0032] In this example, poplar wood is subjected to unilateral surface strengthening treatment, and the poplar wood used is a string-cut board, β 1 is 28°, β 2 60°, chord-radial shrinkage ratio of 1.88, initial moisture content of 8%, and average air-dry density of 0.48g / cm 3 .

[0033] (1) Thermal field control: heat up the hot plate to a target temperature of 180°C, stabilize the temperature at the target temperature of 180°C, and keep the temperature of the cold plate at 20°C.

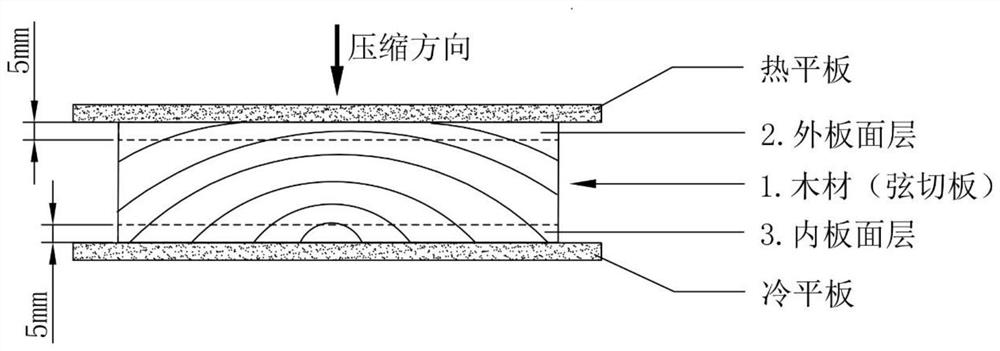

[0034] (2) Compression strengthening: place the inner surface layer of poplar wood on the cold plate, close the press, the outer surface layer of the wood is in contact with the hot plate, and the press compresses the wood to the target thickness in 240 seconds, the compression amount is 8mm , to prepare the reinforcement layer on the outer surface, the preparation process is as follows figure 1 shown.

[0035] (3) Deformation fixation: Raise the temperature of the hot plate to the target temper...

Embodiment 2

[0040] In this embodiment, poplar wood is subjected to one-sided surface strengthening treatment. The poplar wood used is the string cut board, β 1 is 25°, β 2 68°, chord-radial shrinkage ratio 2.09, initial moisture content 13%, average air-dry density 0.50g / cm 3 .

[0041] (1) Thermal field control: heat up the hot plate to a target temperature of 150°C, stabilize the temperature at the target temperature of 150°C, and keep the temperature of the cold plate at 40°C.

[0042] (2) Compression strengthening: the poplar wood is placed on the cold plate, the press is closed, the outer surface layer of the wood is in contact with the hot plate, and the press compresses the wood to the target thickness in 10 seconds, the compression amount is 5mm, and the outer plate is obtained. The strengthening layer of the board surface, the preparation process is as follows figure 1 shown.

[0043] (3) Deformation fixation: Raise the temperature of the hot plate to the target temperature ...

Embodiment 3

[0047] In this example, Okoume wood is strengthened on one side of the surface, and the Okoume wood used is a string-cut board, β 1 is 20°, β 2 65°, chord-radial shrinkage ratio of 1.93, initial moisture content of 11%, and average air-dry density of 0.45g / cm 3 .

[0048] (1) Thermal field control: heat up the hot plate to a target temperature of 130°C, stabilize the temperature at the target temperature of 130°C, and keep the temperature of the cold plate at 30°C.

[0049] (2) Compression strengthening: put the Okoume wood on the cold plate, close the press, the outer surface of the wood is in contact with the hot plate, and the press compresses the wood to the target thickness in 120 seconds, the compression amount is 5mm, and the obtained The reinforcement layer on the outer surface, the preparation process is as follows: figure 1 shown.

[0050] (3) Deformation fixation: Raise the temperature of the hot plate to the target temperature of 200°C and keep the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com