A kind of preparation method of vanadium slag/calcium oxide diffusion couple

A calcium oxide and diffusion couple technology, applied in the field of material research, can solve the problems of not finding calcium oxide, not finding it, deliquescence, etc., to reduce deliquescence degeneration and avoid cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a method for preparing a vanadium slag / calcium oxide diffusion couple, comprising the following steps:

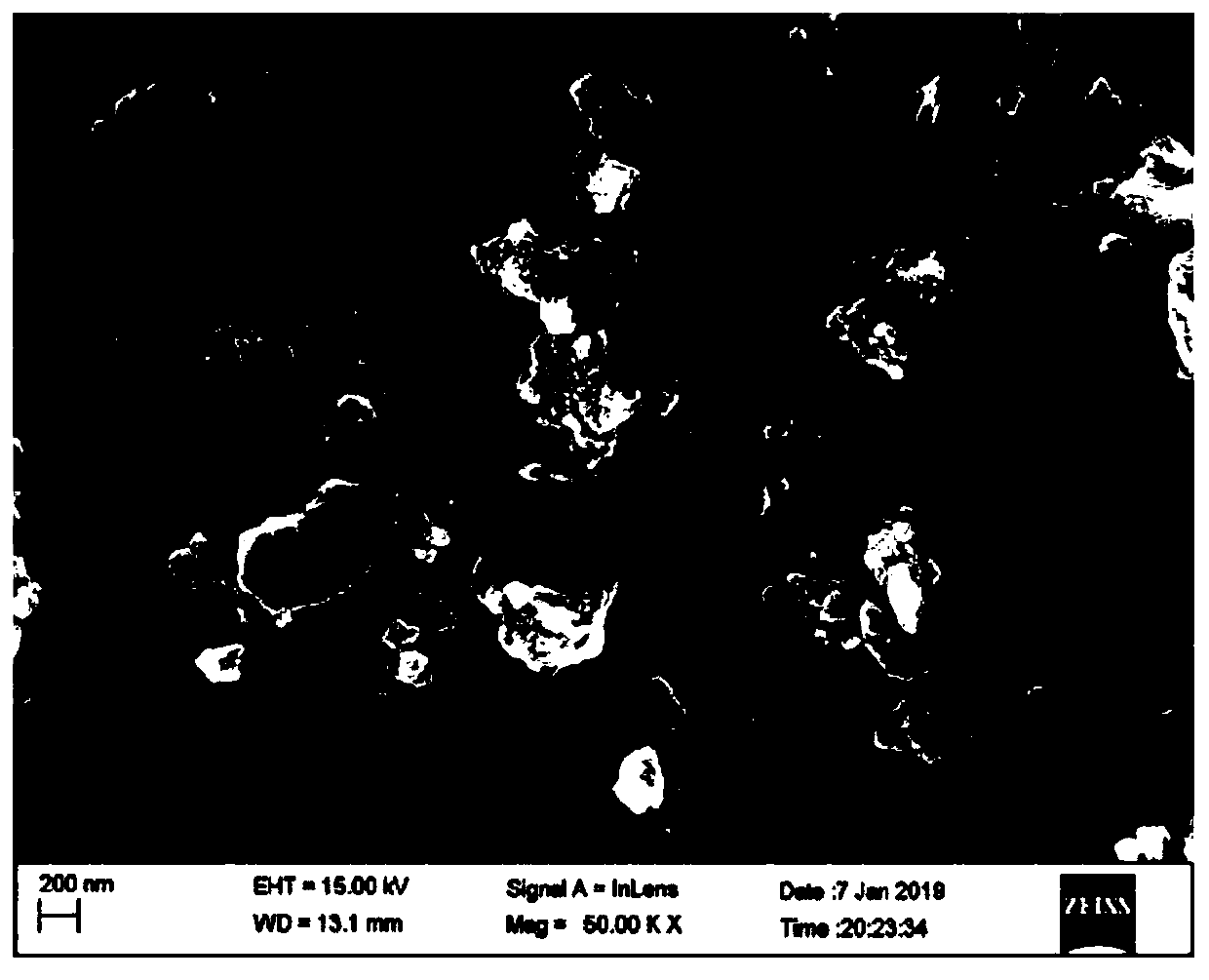

[0051] S1. Use a high-energy ball mill to mill 30g of calcium oxide powder at a speed of 150r / min for 3 hours, then dry it, and use a field emission scanning electron microscope-energy dispersive spectroscopy (SEM-EDS) to characterize the calcium oxide powder. The characterization results are as follows figure 1 shown. Depend on figure 1 It can be seen that the particle size of the calcium oxide powder is relatively uniform, and the particle size is about 200nm.

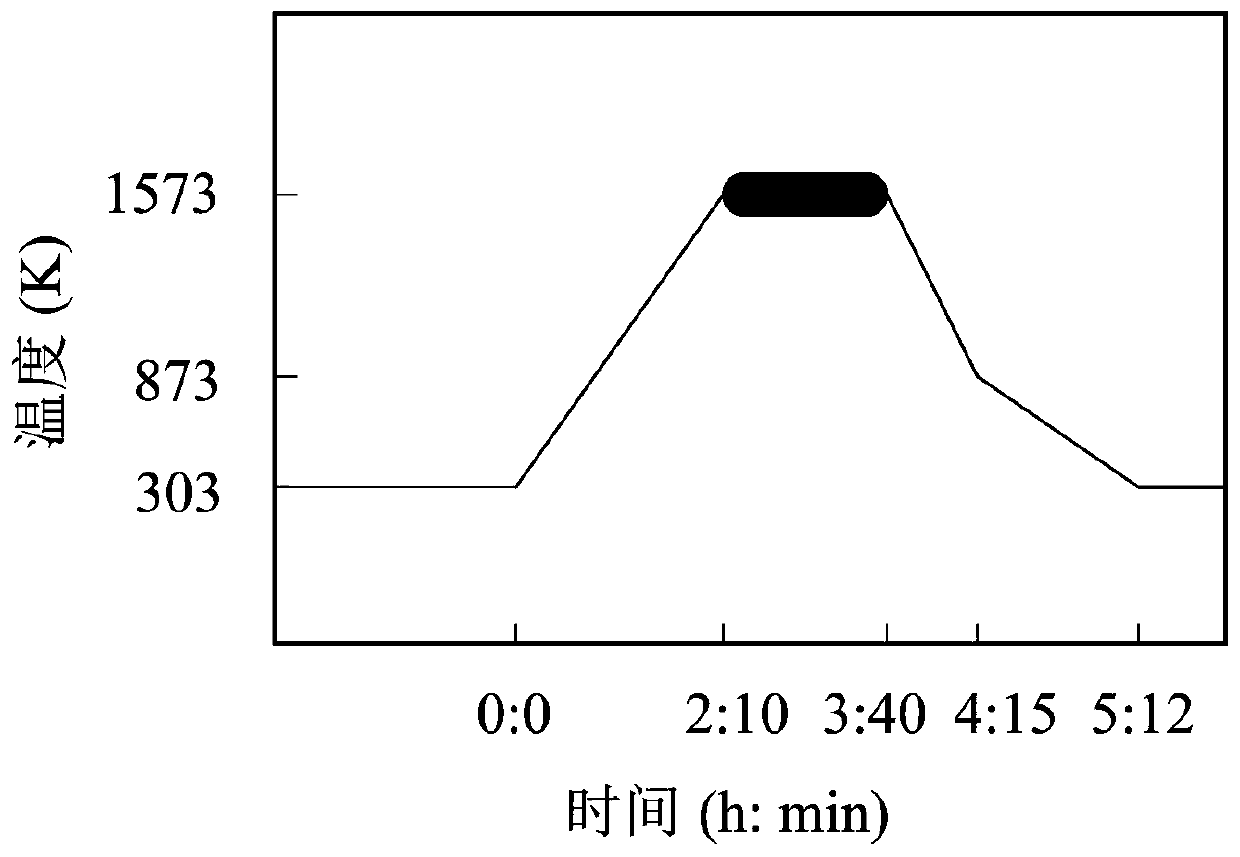

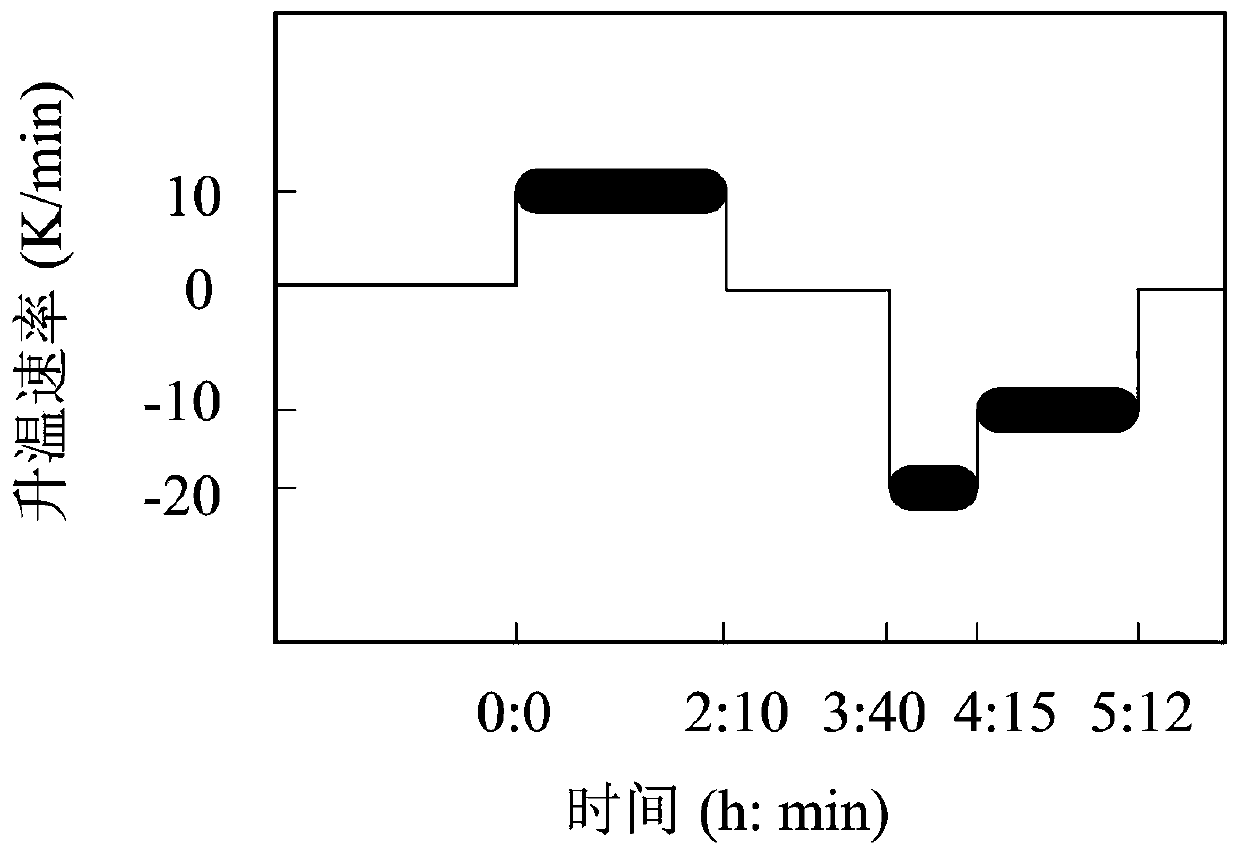

[0052] The calcium oxide powder was put into a stainless steel mold with an inner diameter of 30mm, and a pressure of 14130N was applied by a tablet press to press the calcium oxide powder into a tablet with a diameter of 30mm and a thickness of 5mm. Place the prepared sheet in a vacuum hot-press furnace for sintering: set the pressure of the vacuum hot-press furnace to 14130N, wh...

Embodiment 2

[0060] This embodiment provides a method for preparing a vanadium slag / calcium oxide diffusion couple, comprising the following steps:

[0061] S1. Mill 20g of calcium oxide powder with a high-energy ball mill at a speed of 200r / min for 1 hour, and then dry it. Put the calcium oxide powder after ball milling and drying into a stainless steel mold with an inner diameter of 30mm, and press the calcium oxide powder into a tablet with a diameter of 30mm and a thickness of 5mm by applying a pressure of 13800N by a tablet press. Place the prepared sheet in a vacuum hot-press furnace for sintering: set the pressure of the vacuum hot-press furnace to 13800N, when the vacuum degree reaches 160Pa, raise the temperature to 1563K at a heating rate of 10K / min, and after holding for 80min, heat it to 20K / min cooling rate down to 873K, and then down to room temperature at a cooling rate of 10K / min. Then the tablet is taken out, and the upper and lower circular surfaces of the tablet are gr...

Embodiment 3

[0068] This embodiment provides a method for preparing a vanadium slag / calcium oxide diffusion couple, comprising the following steps:

[0069] S1. Mill 30g of calcium oxide powder with a high-energy ball mill at a speed of 300r / min for 2 hours, and then dry it. Put the calcium oxide powder after ball milling and drying into a stainless steel mold with an inner diameter of 30mm, and press the calcium oxide powder into a tablet with a diameter of 30mm and a thickness of 5mm by applying a pressure of 14890N by a tablet press. Place the prepared sheet in a vacuum hot-press furnace for sintering: set the pressure of the vacuum hot-press furnace to 14890N, when the vacuum reaches 180Pa, raise the temperature to 1553K at a heating rate of 10K / min, and after holding for 100min, heat it up to 1553K at a temperature of 20K / min cooling rate down to 873K, and then down to room temperature at a cooling rate of 10K / min. Then the tablet is taken out, and the upper and lower circular surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com