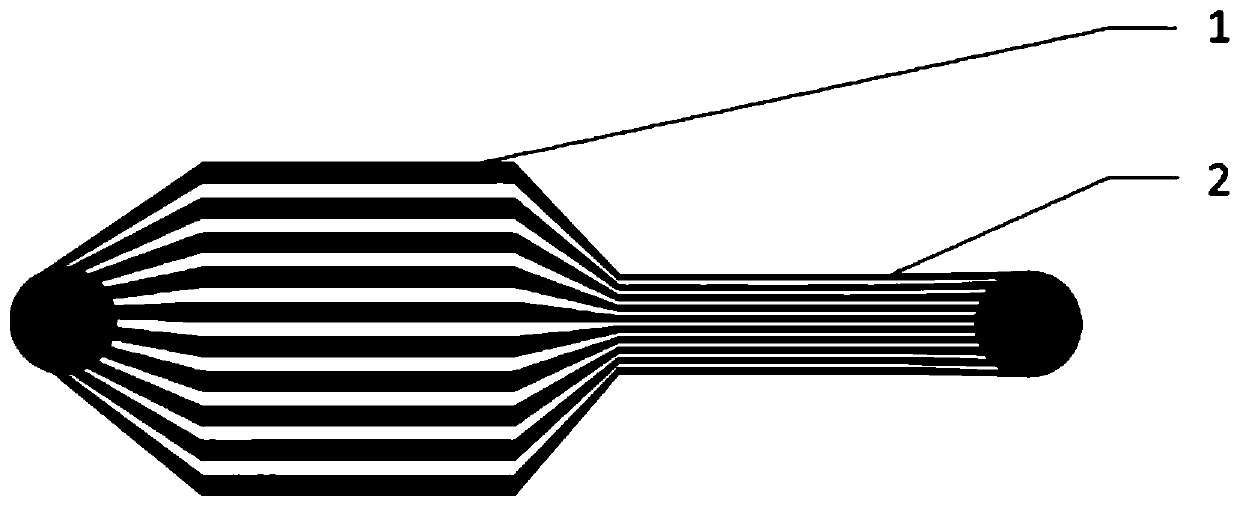

Flexible array microelectrode manufacturing method

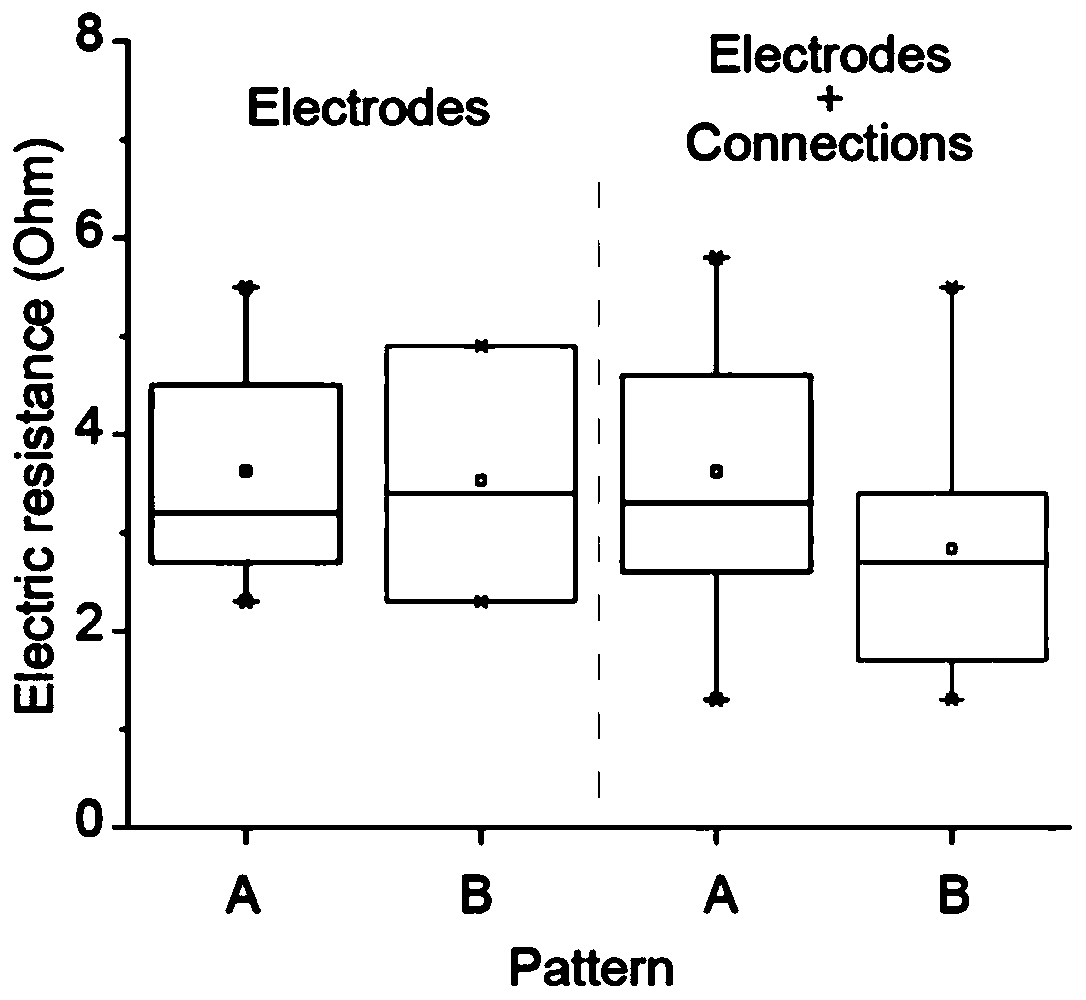

A flexible array and micro-electrode technology, which is applied in directions such as the use of electric/magnetic devices to transmit sensing components, can solve problems such as large electrode resistance, and achieve the effects of small thickness, simple preparation steps and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a method for preparing a flexible tactile sensor array microelectrode, comprising the following steps:

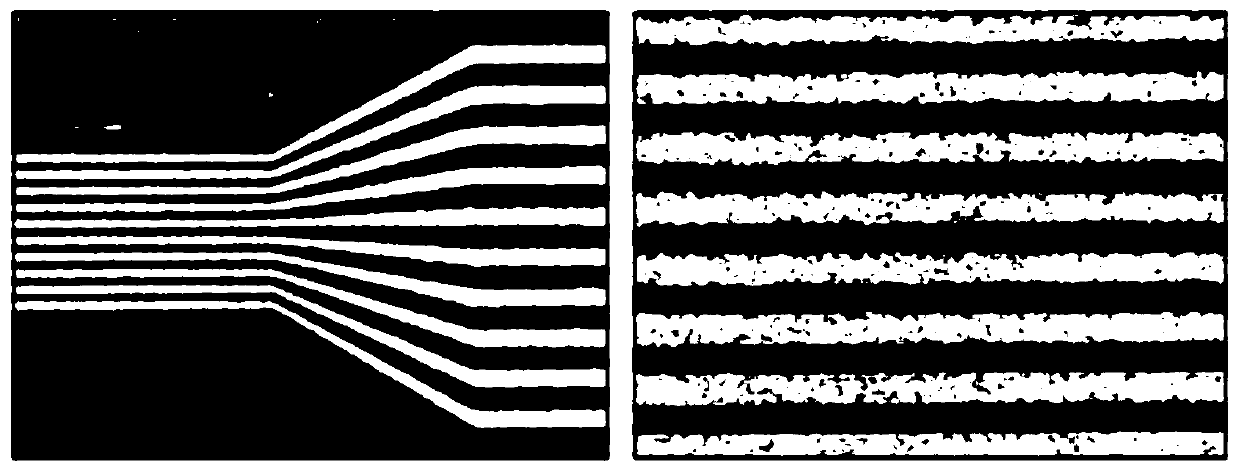

[0046] (1) Customize the mask of the electrode pattern. Customize the mask of the electrode pattern according to the design requirements, such as figure 2 shown;

[0047] (2) Cut the photosensitive dry film to the same size as the mirror stainless steel plate, and seal the photosensitive dry film and the mirror stainless steel plate well through a plastic sealing machine to ensure that the photosensitive dry film and the mirror stainless steel plate are closely attached.

[0048] (3) The side of the mask with ink is in contact with the side of the plastic-sealed photosensitive dry film and fixed with adhesive tape, and placed in an exposure machine for ultraviolet exposure. The exposure time is 40s. The shape of the channel can be projected on the photosensitive dry film.

[0049] (4) Prepare a developing solution with deionized water and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com