Rolling device and method for realizing rapid water drainage and gas exhaust of rubber soil roadbed

A technology of rubber soil and roadbed, which is applied in the direction of soil protection, roads, roads, etc., can solve the problems of low construction efficiency, shorten the construction period of roadbed rolling in rainy seasons, and the inability of rubber soil to effectively function, and achieve rolling efficiency improvement, scraping The mud effect is good and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

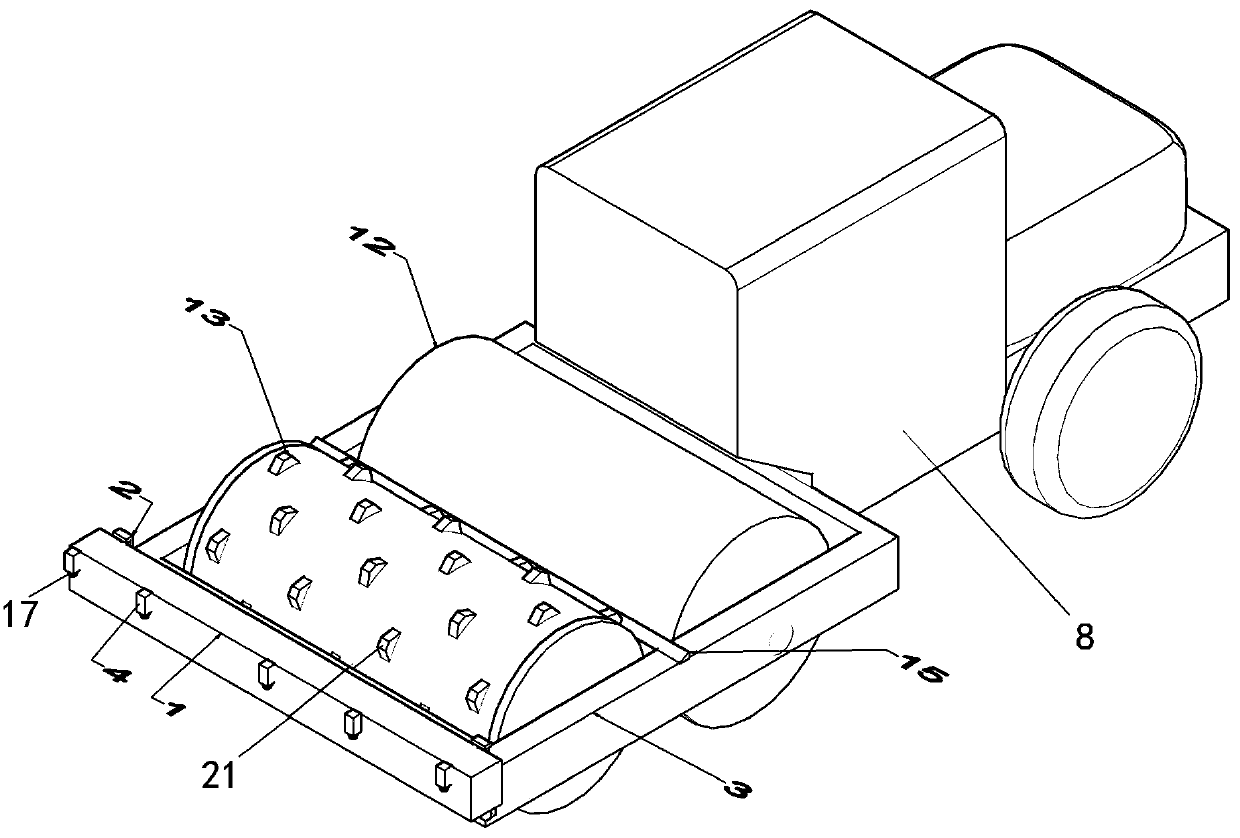

[0048] like Figure 1-Figure 10 As shown, a rolling device for realizing rapid drainage and exhaust of rubber soil roadbed includes a double-roller roller body 8, a fixed bracket 3 is installed in front of the double-roller roller body 8, and a front Rolling roller 13 and back rolling roller 12,

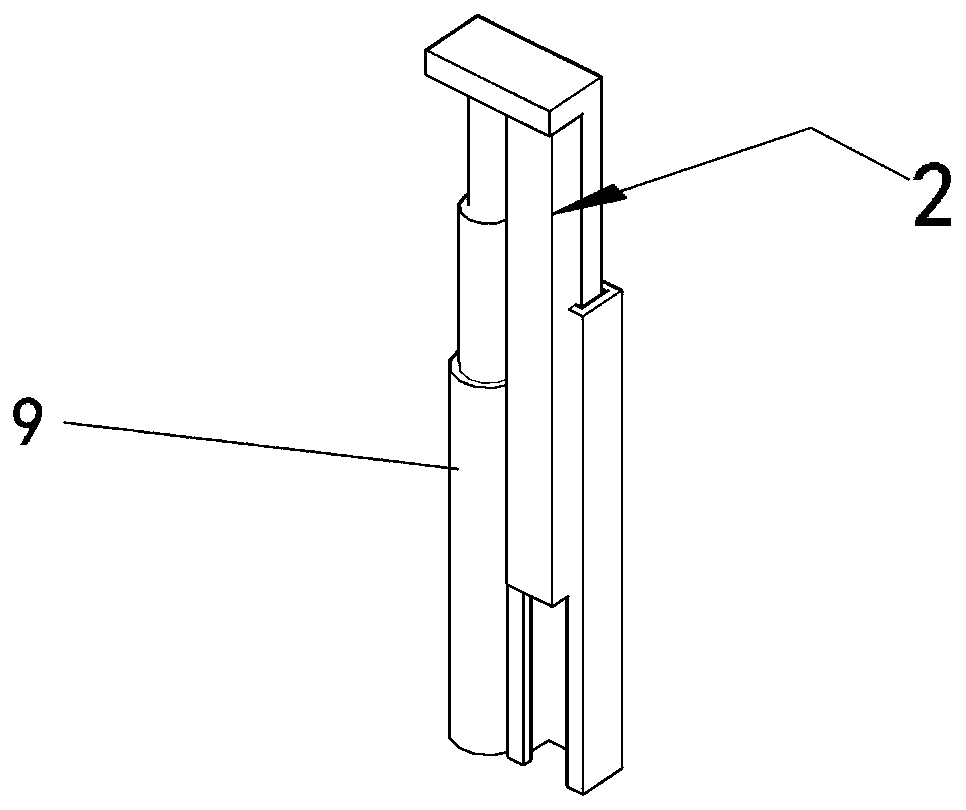

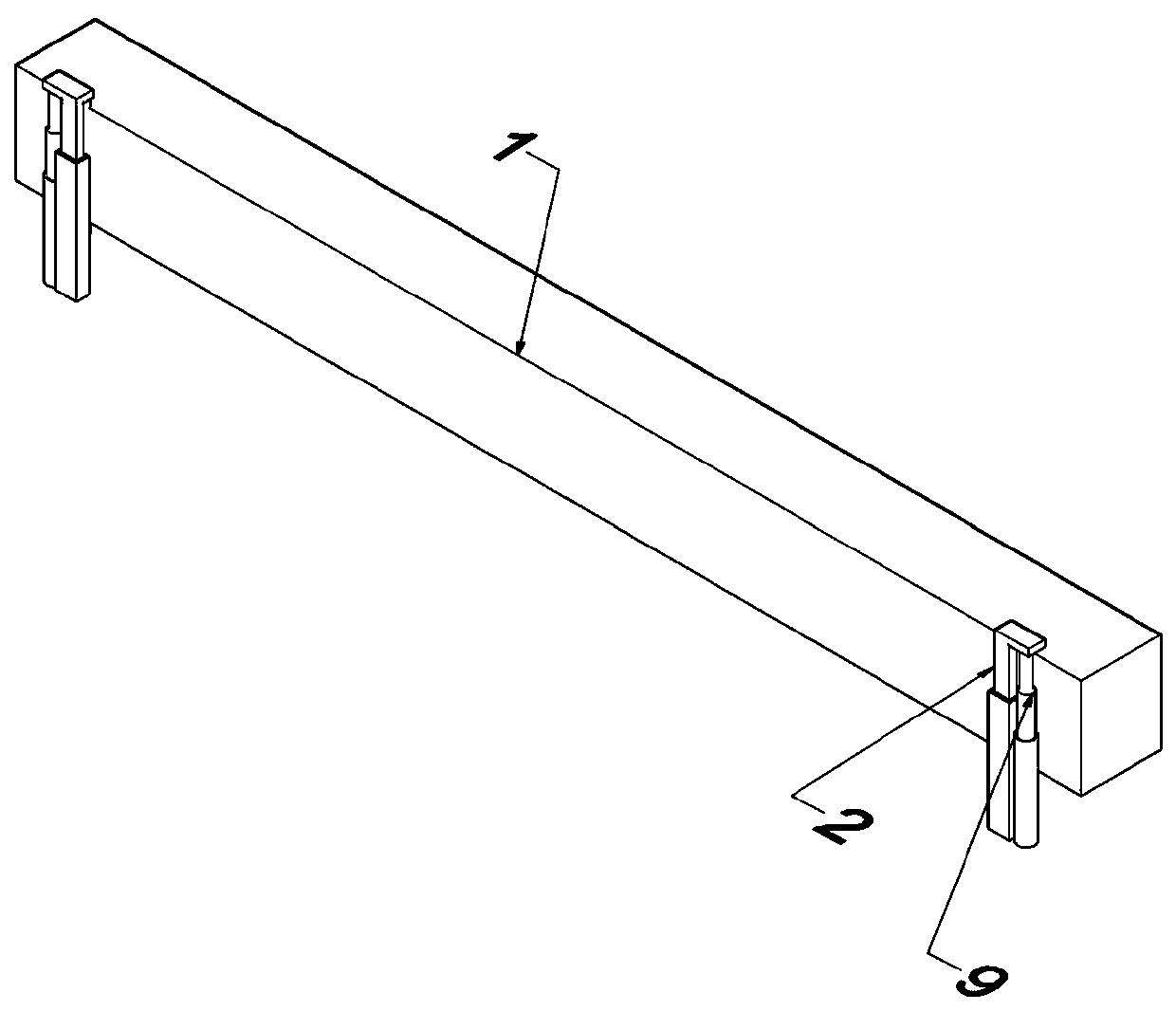

[0049] Lifting rods 9 with sliders 2 are respectively fixed on both sides of the front end of the fixed bracket 3, and the microwave heating device 1 is installed on the front end of the fixed bracket 3 through the slider 2;

[0050] The front rolling roller 13 is a sheep foot roller, including an outer cylinder 20, the outer cylinder 20 is an embedded steel pipe structure composed of an inner cylinder steel plate and an outer cylinder steel plate, and a supporting layer 14 is arranged between the inner cylinder steel plate and the outer cylinder steel plate The support layer 14 is composed of multiple arc-shaped plates 14-1 spliced together, each side of the arc-shaped plate 14-1...

Embodiment 2

[0061] A method for the above-mentioned rolling device to realize rapid drainage and exhaust of rubber soil roadbed, the method comprises the following steps:

[0062] Step 1: During the rolling process, the distance sensor 4 and the humidity sensor 17 at the front end of the fixed bracket 3 sense the humidity of the soil and the height of the microwave heating device 1 respectively, adjust the power of the microwave heating device 1 and start the lifting rod 9 according to the data Adjust the height of the microwave heating device 1 so that the microwave heating device 1 rapidly heats the soil body in front of and below the rolling roller 13;

[0063] Step 2: The bumps 21 on the front rolling roller 13 penetrate into the soil, and with the vibration of the vibrating device 5, the sheep's feet gradually penetrate into the soil and loosen the soil;

[0064] Step 3: Open the suction device 7 to pump out the gas, and the water vapor in the soil is quickly discharged through the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com