Vertical slurry crusher

A pulverizer and slurry technology, applied in grain processing and other directions, can solve the problems of different material sizes, high fine powder content, low pulverization efficiency, etc., and achieve the effect of uniform material particles, high pulverization efficiency and reasonable internal structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] the following to Figure 1 to Figure 24 Shown, the specific embodiment of the present invention is described.

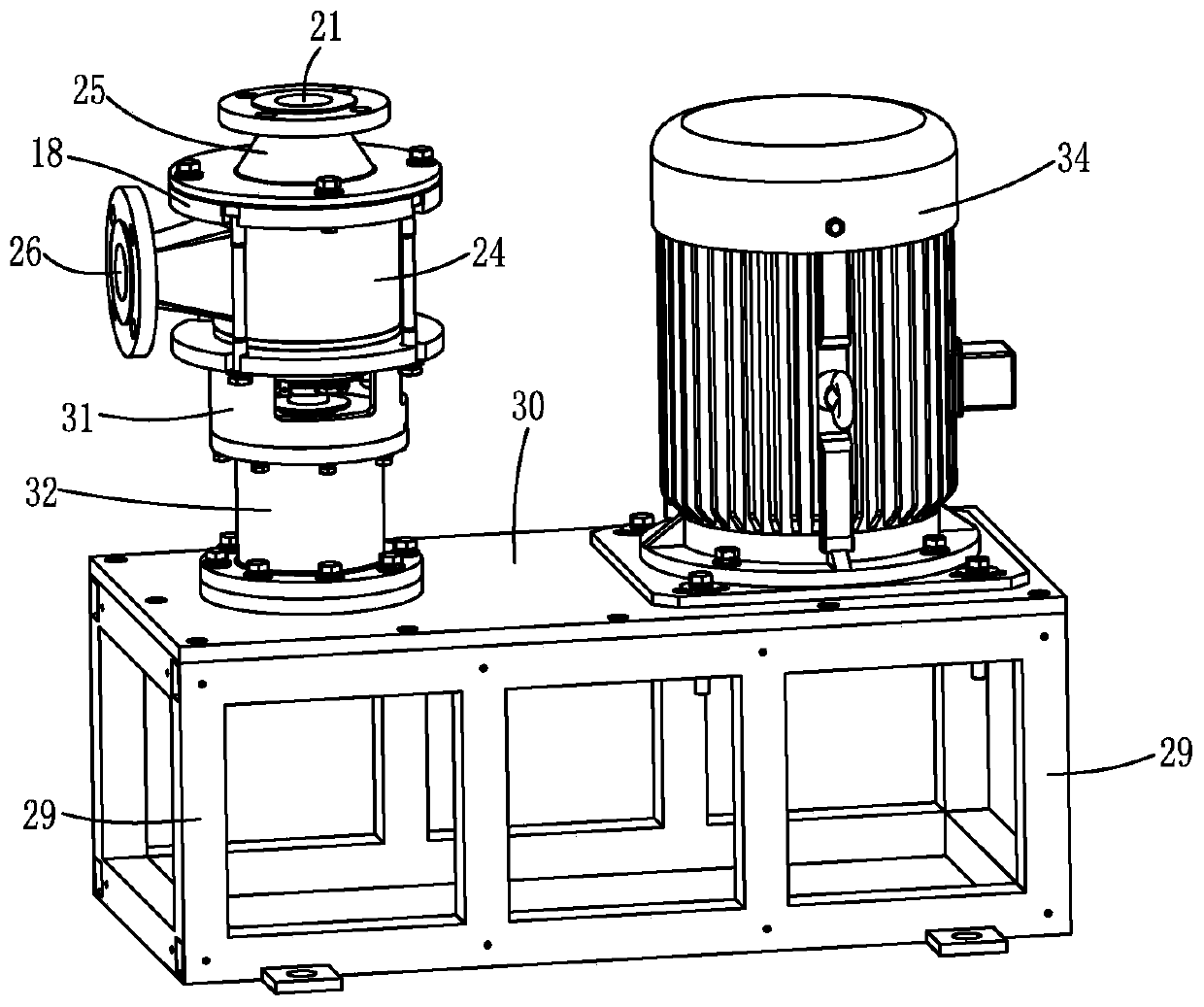

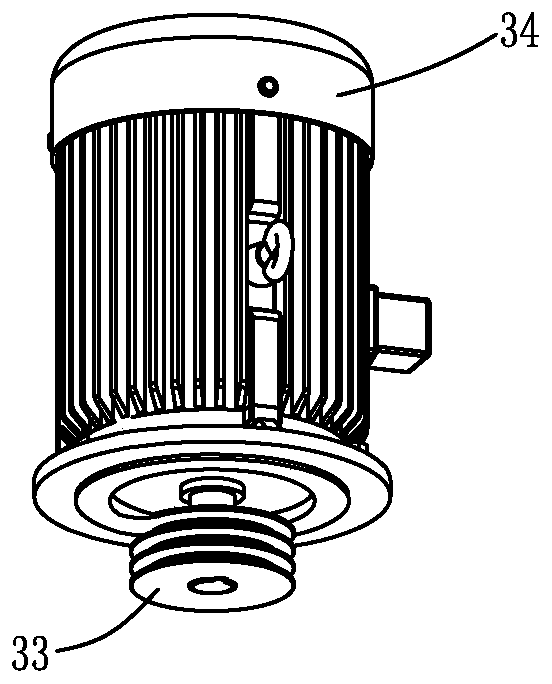

[0042] like figure 1 As shown, the vertical pulp pulverizer of the present invention is provided with a mounting frame 29, and a mounting plate 30 is arranged above the mounting frame 29. The vertical pulp pulverizer is fixedly installed on one side of the mounting plate 30, and the rotating shaft of the vertical pulp pulverizer The lower end of the 4 passes through the mounting plate 30, and the belt pulley 33 is installed at the lower end of the rotating shaft 4. The other side on the mounting plate 30 is fixedly installed motor 34, and the main shaft 35 of motor 34 passes mounting plate 30, as image 3 Shown, pulley 33 is also installed at the lower end of motor 34 main shafts 35, and drive belt is loaded onto between the two pulleys 33. Just formed the vertical pulp pulverizer unit of the present invention.

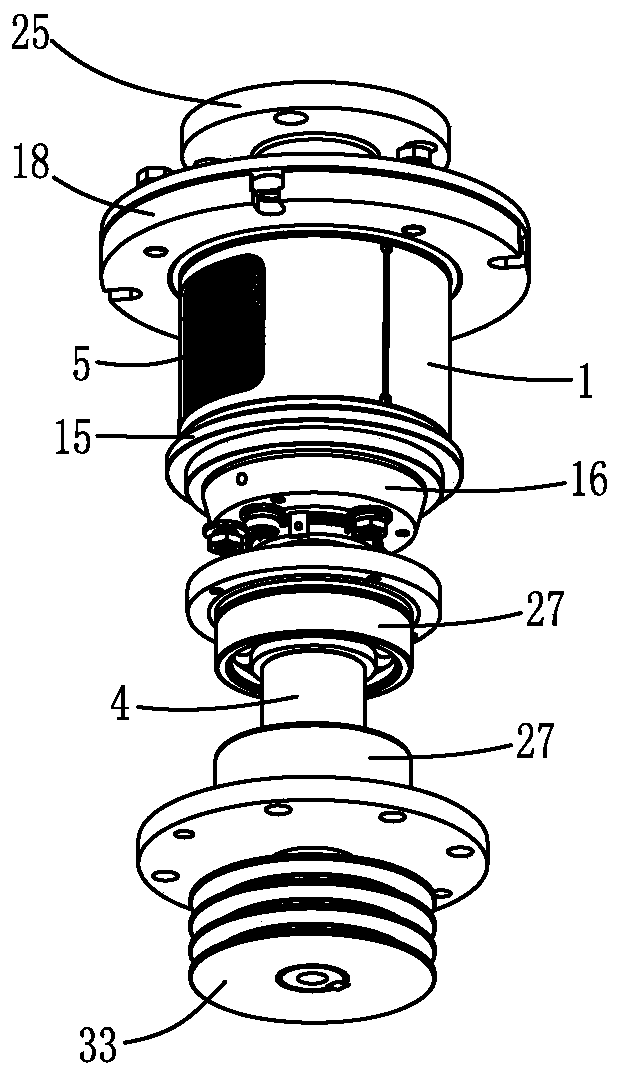

[0043] like figure 2 , Figure 4 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com